Cylindrical workpiece spring clamping device used for linear cutting

A cylindrical workpiece and spring clamping technology, applied in the field of machining, can solve the problems of precision requirements affecting dimensional accuracy and geometric tolerance, easy deformation, poor rigidity, etc. long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

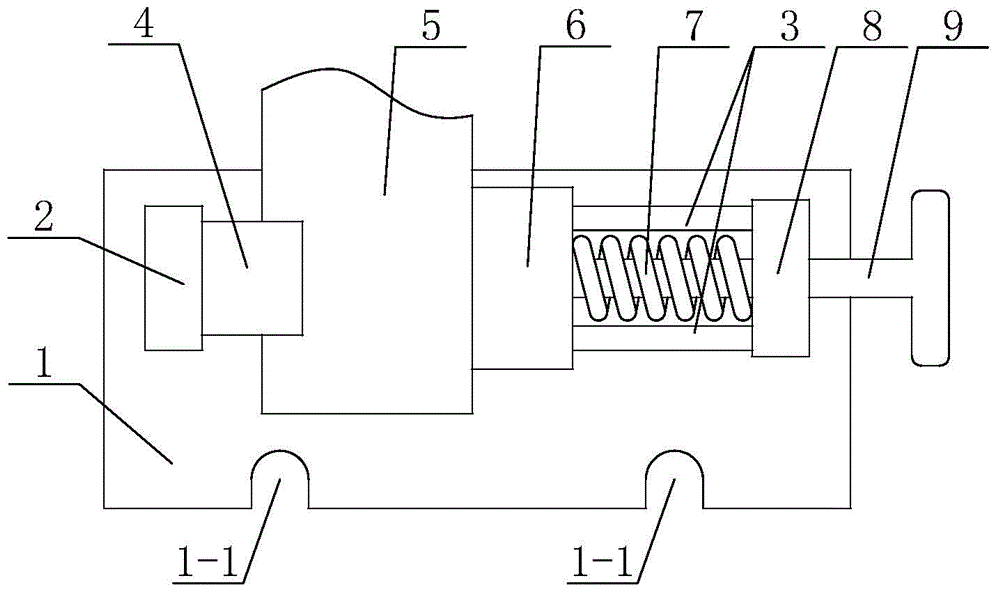

[0022] like figure 1 and figure 2 The shown spring clamping device for a cylindrical workpiece for wire cutting includes a base plate 1 with an open fixing groove 1-1 on one side, and a V-groove pad 4 and a V-groove pad 4 and A sliding head 6, two smooth bars 3 parallel to each other and used to support the sliding head 6, a compression spring 7 for driving the sliding T-shaped pull rod 9 for tightening spring 7; both ends of the upper side of the bottom plate 1 are respectively fixed with a pad support 2 and a pull rod support 8, and the cushion support 2 and the pull rod support 8 are fixedly installed There are two smooth bars 3 , the V-groove pad 4 is fixedly installed on the inner side of the upper end of the pad support 2 , and the sliding pressure head 6 is slidably installed on the two smooth bars 3 . The T-shaped pull rod 9 is slidably installed in the middle of the pull rod support 8 through a light hole. The compression spring 7 is sleeved between the tie rod su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com