Preparation method of antibacterial silver molybdate and graphite-phase carbon nitride composite visible-light-induced photocatalyst

A graphite phase carbon nitride and catalyst technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, botanical equipment and methods, etc., can solve the problem of low photocatalytic performance and achieve excellent antibacterial properties and high catalytic efficiency , The effect that the preparation conditions are easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of lamellar graphite phase carbon nitride

[0024] Under uniform stirring, slowly add 7g of ammonium chloride and 3.5g of melamine to 28mg of water, stir at room temperature for 20 minutes, heat to 100°C, and continue stirring for 30 minutes until the water is completely volatilized. The dried ammonium chloride and melamine mixture is put into a semi-closed crucible, put into the muffle furnace, reacted at 400°C for 4 hours, closed the muffle furnace, and ground.

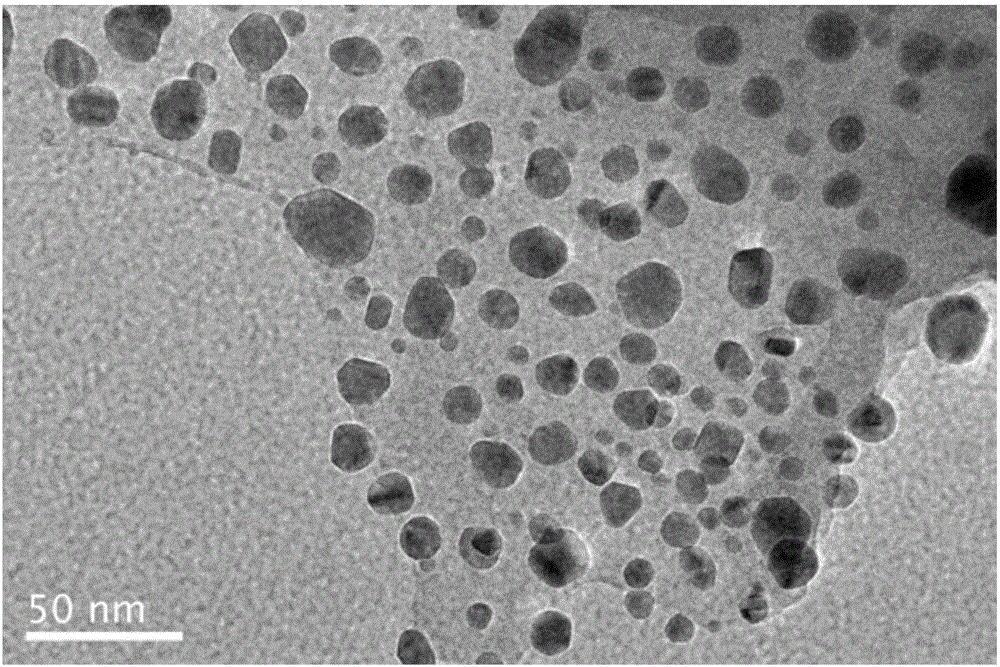

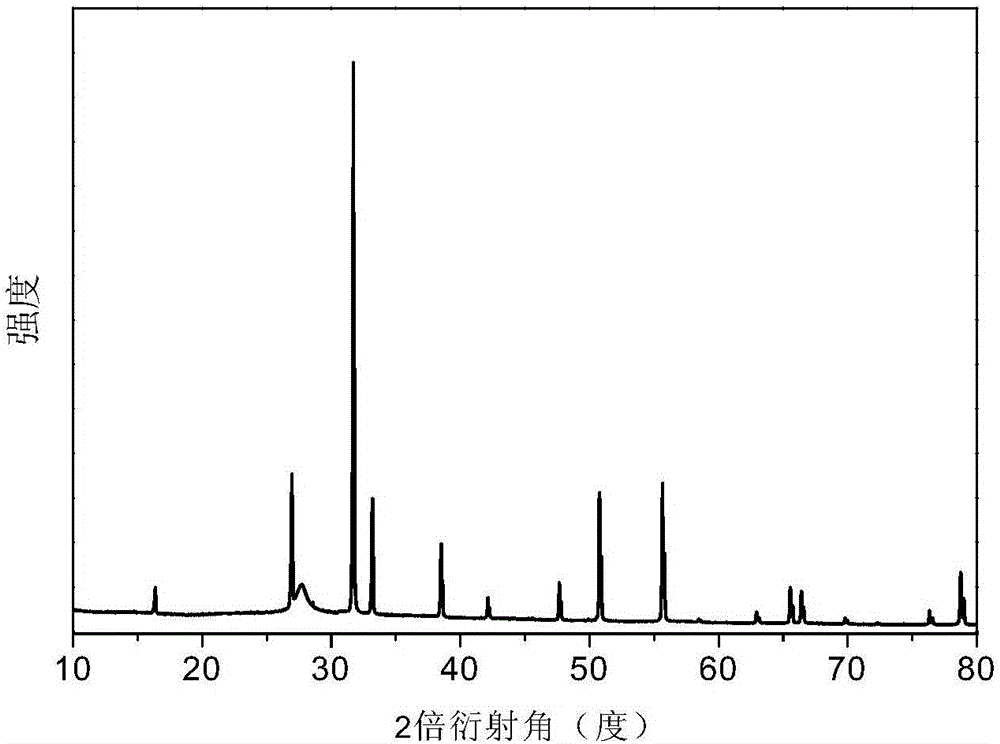

[0025] (2) Silver molybdate doped with g-C 3 N 4 Preparation of composite photocatalyst

[0026] Weigh 0.5 g of silver nitrate and dissolve it in water, then weigh 0.4 g of the lamellar graphite phase carbon nitride prepared in step (1) and add it to the silver nitrate solution, sonicate for 5 minutes, and stir for 10 minutes to form solution A. Weigh 0.25 g of ammonium molybdate tetrahydrate and dissolve it in water to form solution B. Subsequently, solution B was slowly added to solution A to adj...

Embodiment 2

[0028] (1) Preparation of lamellar graphite phase carbon nitride

[0029] Under constant stirring, slowly add 7g of ammonium chloride and 4.2g of melamine to 35mg of ethanol. Stir at a constant speed for 60 minutes at room temperature, heat to 100°C, and continue stirring for 60 minutes until the ethanol is completely volatilized. The dried ammonium chloride and melamine The mixture was put into a semi-closed crucible, calcined at 450°C, reacted for 6 hours, turned off the muffle furnace, and ground.

[0030] (2) Silver molybdate doped with g-C 3 N 4 Preparation of composite photocatalyst

[0031] Weigh 0.5g of silver nitrate and dissolve it in ethylene glycol, then weigh 0.475g of the lamellar graphite phase carbon nitride prepared in step (1) and add it to the silver nitrate solution, sonicate for 10 minutes, and stir for 20 minutes to form solution A . Weigh 0.35 g of sodium molybdate and dissolve it in ethylene glycol to form solution B. Subsequently, solution B was slowly add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com