High-performance forward permeable membrane and electrostatic spinning preparation method thereof

A forward osmosis membrane, high-performance technology, applied in the field of membrane separation, can solve the problems of unsatisfactory salt cutoff rate of forward osmosis membrane, complex hydrophilic and hydrophobic interpenetrating nanofiber method, etc., to achieve hydrophilic improvement, increase water flux and The effect of salt cutoff and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

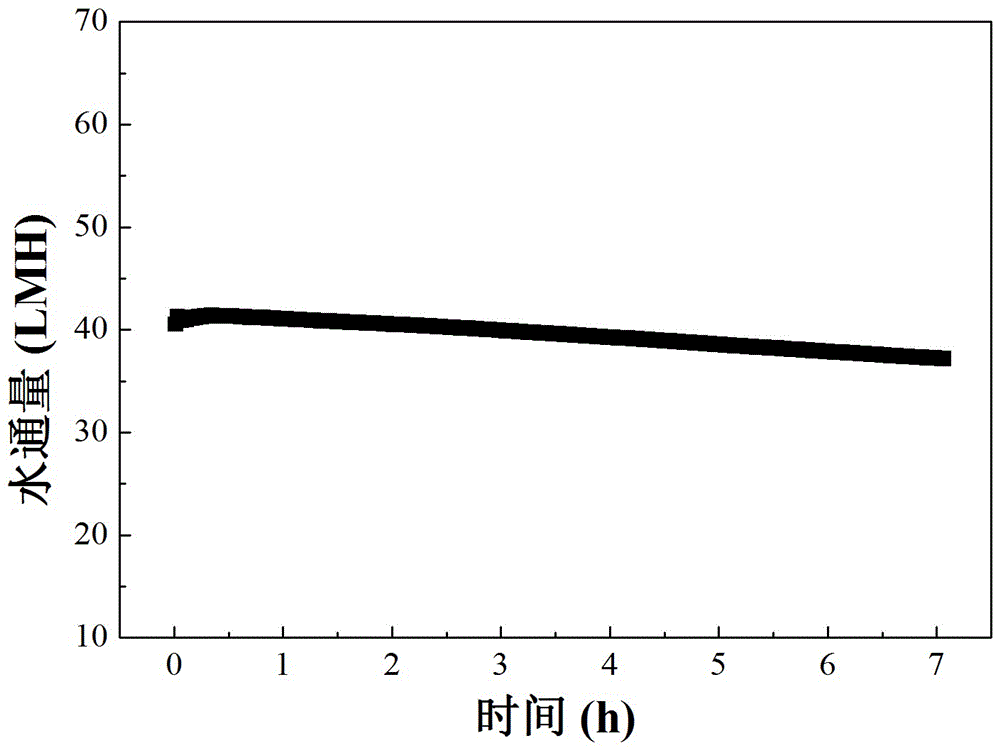

[0027] Dissolve 0.05g carbon nanotubes in a mixed solvent of 10g N-N dimethylformamide (DMF) and NN dimethylacetamide (DMAc) (DMF: DMAc=1:1), and configure a carbon concentration of 0.5% Nanotube solution: Dissolve 1g of polyacrylonitrile (PAN) in the above mixed solution and stir evenly to prepare a spinning solution with a concentration of 10%. The carbon nanotube / PAN solution was added to the syringe, the flow rate of the syringe was adjusted to 1.2 mL / h, and the distance between the syringe and the receiving device was 15 cm, and the nanofibers were prepared by spinning under 15 kV high voltage electrostatic. The obtained composite fiber membrane is dried in an oven at 60° C. for 12 hours, and the dried composite fiber membrane is laminated through a laminator to obtain a compacted composite fiber membrane.

[0028] Take the above-mentioned compacted composite fiber membrane as a support layer, soak it in a 3% m-phenylenediamine (MPD) aqueous solution for 2 minutes, take it o...

Embodiment 2

[0033] Dissolve 0.35g carbon nanotubes in a mixed solvent of 10g N-N dimethylformamide (DMF) and NN dimethylacetamide (DMAc) (DMF: DMAc=3:1), and configure a carbon concentration of 3.5% Nanotube solution: Dissolve 1.5g of polyacrylonitrile (PAN) in the above mixed solution and stir evenly to prepare a spinning solution with a concentration of 15%. The carbon nanotube / PAN solution was added to the spinning jet head, the flow rate of the spinning jet head was adjusted to 1.5 mL / h, the spinning jet head was 20 cm away from the receiving device, and the nanofibers were prepared by spinning under 25kV high voltage electrostatic. The obtained composite fiber membrane is placed in an oven at 70° C. and dried for 8 hours, and the dried composite fiber membrane is laminated through a laminator to obtain a compacted composite fiber membrane.

[0034] Take the above-mentioned compacted composite fiber membrane as a supporting layer, soak it in a 1% o-phenylenediamine aqueous solution for 1...

Embodiment 3

[0037] Dissolve 0.5 g of carbon nanotubes in 10 g of tetrahydrofuran to prepare a 5% carbon nanotube solution; dissolve 1.2 g of a mixture of polyacrylonitrile and polyvinyl alcohol (mass ratio 1:1) in the above mixed solution, Stir evenly to obtain a spinning solution with a concentration of 12%. Add the carbon nanotube / (PAN+PVA) solution into the spinning jet head, adjust the flow rate of the spinning jet head to 1mL / h, the spinning jet head is 10cm away from the receiving device, and spin it under 20kV high voltage electrostatic. fiber. The obtained composite fiber membrane is placed in an oven at 70° C. and dried for 8 hours, and the dried composite fiber membrane is laminated through a laminator to obtain a compact composite fiber membrane.

[0038] Take the above-mentioned compacted composite fiber membrane as a supporting layer, soak it in a 5% bisphenol aqueous solution for 3.5 minutes, take it out, remove the excess solution on the surface, and then place it in 5% isoph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com