Device and method for preparing tobacco source basic cigarette flavor material for novel tobacco products

A technology for a tobacco product and a preparation device, applied in the field of tobacco, can solve the problems of insufficient overall physiological satisfaction, insufficient aroma harmony, and insufficient aroma and rhythm, and achieve the effects of less harmful components, convenient mass production, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

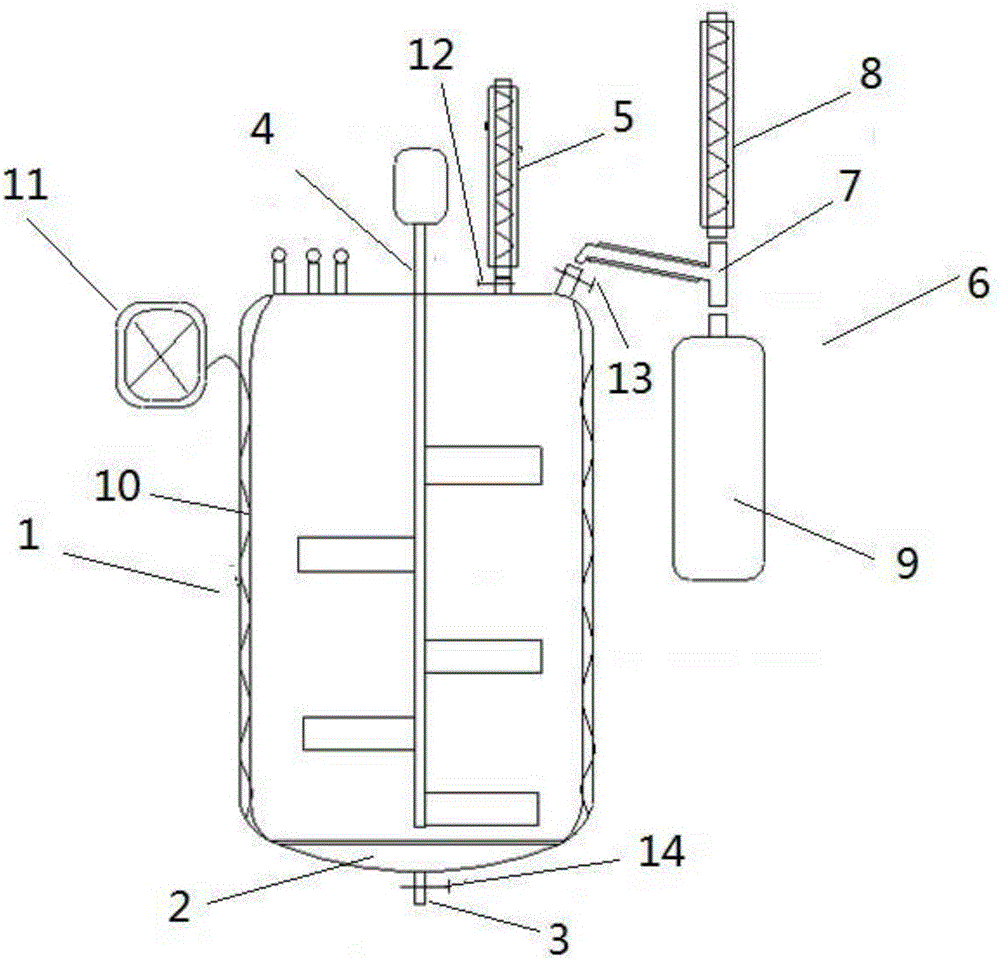

[0058] In advance, the heating temperature of the tobacco source basic smoke flavor raw material preparation device for new tobacco products is kept constant at 150°C, and the airtightness of the system and the condensation medium are checked. Weigh 60g of 20 mesh Zimbabwe 2014 L1O grade flue-cured tobacco powder and quickly put it into the special device, immediately close the system, and at the same time turn on the stirring motor and adjust the speed to 400 rpm to stir the tobacco raw materials. After heating for 3.5 hours, the collected The Maillard reaction is removed with the caramelization products. Replace with a clean collection bottle, quickly raise the temperature to 250°C at a heating rate of 20°C / min, stop heating after 20 minutes of dry distillation and pyrolysis, and remove the collected dry distillation pyrolysis product when the temperature of the material drops to room temperature. Close valve A, open valve B; quickly add 6 times the weight of 90% ethanol, an...

Embodiment 2

[0061] In advance, the heating temperature of the tobacco source basic smoke flavor raw material preparation device for new tobacco products is kept constant at 170°C, and the airtightness of the system and the condensation medium are checked. Weigh 50g of 40-mesh self-made flue-cured tobacco leaf group powder and quickly put it into the special device, immediately close the system, and at the same time turn on the stirring motor and adjust the speed to 300 rpm to stir the tobacco raw materials. After heating for 3 hours, the collected Mera De-reaction with caramelization products removed. Replace with a clean collection bottle, quickly raise the temperature to 270°C at a heating rate of 30°C / min, stop heating after 18 minutes of dry distillation, and remove the collected dry distillation pyrolyzate when the temperature of the material drops to room temperature. Close valve A and open valve B; quickly add 5 times the weight of 85% ethanol, raise the temperature to 58 ° C, and ...

Embodiment 3

[0064] In advance, the heating temperature of the tobacco source basic smoke flavor raw material preparation device for new tobacco products is kept constant at 175°C, and the airtightness of the system is checked. Weigh 80g of the self-prepared flue-cured tobacco leaf group raw material that has been cut twice by the shredding machine and quickly put it into the special device, immediately close the system, and at the same time turn on the stirring motor and adjust the speed to 500 rpm to stir the tobacco raw material and heat it for 2.5 hours Afterwards, remove the collected Maillard reaction products. Replace with a clean collection bottle, quickly raise the temperature to 230°C at a heating rate of 20°C / min, stop heating after 30 minutes of dry distillation, and remove the collected dry distillation pyrolyzate when the temperature of the material drops to room temperature. Close valve A, open valve B; quickly add 6 times the weight of 20% ethyl acetate-80% ethanol solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com