Dried passion fruit and preparing method thereof

A passion fruit and preserved fruit technology, applied in confectionary, confectionary industry, food science, etc., can solve problems such as adverse effects on human health, damage to the integrity of passion fruit, and water loss on the surface of preserved fruit, so as to save production time and manpower , the effect of retaining the original flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Prepare passion fruit preserved fruit according to the following steps:

[0044] 1. Selection and cleaning: Select high-quality fresh passion fruit for cleaning.

[0045] 2. Exfoliation: Exfoliate the cuticle of the passion fruit with a machine, and then wash it with 1% salt water for 8 minutes.

[0046] 3. Piercing treatment: Prick 3 holes on the surface of the passion fruit, deep into the pulp layer.

[0047] 4. Prepare sugar solution: The ingredients of the sugar solution are: 100 kg of boiled water at a temperature of 100°C, 60 kg of white granulated sugar, and 10 kg of preserved fruit syrup. After the sugar liquid is prepared in the steam jacketed pot, it is poured into the barrel. The Brix range of the sugar liquid is 40 degrees Brix.

[0048] 5. Soak in sugar solution: put the passion fruit into the boiling sugar solution or cool the sugar solution to 50°C before putting it in, and soak for 36 hours. There is no need to stir during this period, and the product...

Embodiment 2

[0054] The process of this embodiment is basically the same as that of Example 1, and the adjustments of its formula and process parameters are shown in Table 1 and Table 2 for details.

[0055] Table 1 formula ratio

[0056] components

Example 1

Example 2

Example 3

Comparative example 2

Comparative example 3

Comparative example 4

Passion fruit / kg

100

100

100

100

100

100

White sugar / kg

30

20

25

50

10

5

Maltose / kg

5

1

-

-

10

-

Preserved fruit syrup / kg

-

-

3

-

-

20

Glucose powder / g

300

300

300

-

300

300

Finished Moisture Content

25%

22%

30%

26%

40%

12%

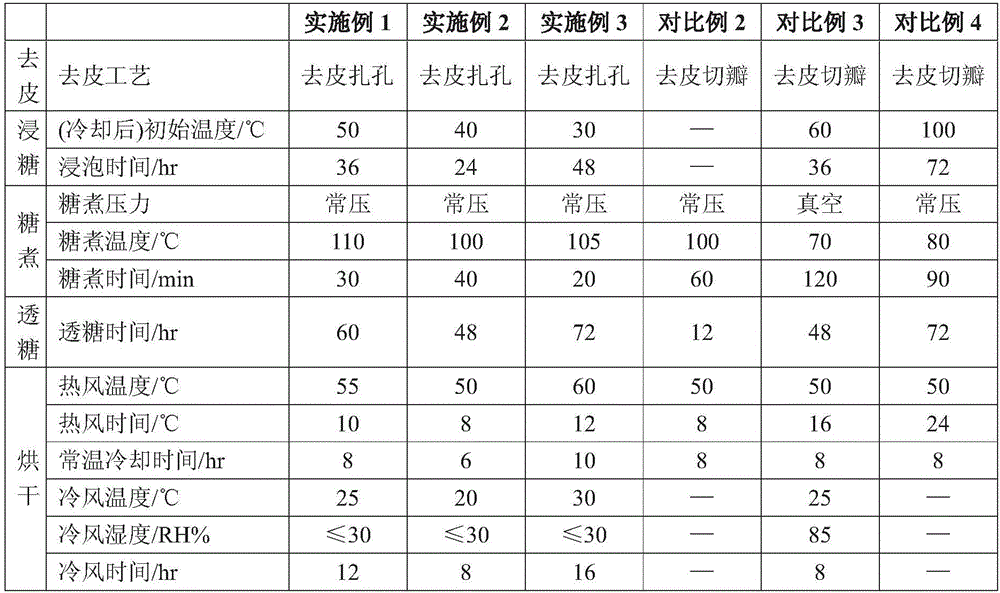

[0057] Table 2 process parameters

[0058]

Embodiment 3

[0060] The process of this embodiment is basically the same as that of Example 1, and the adjustments of its formula and process parameters are shown in Table 1 and Table 2 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com