Blood fat-reducing probiotic fermented milk and preparation method thereof

A technology of probiotics and fermented milk, which is applied in the field of hypolipidemic probiotic fermented milk and its preparation, can solve the problems of slowness, non-growth and reproduction of probiotics, and impractical application, and achieve short fermentation time, high content of probiotics, Significant effect of lowering blood fat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1 (preparation of fermented milk):

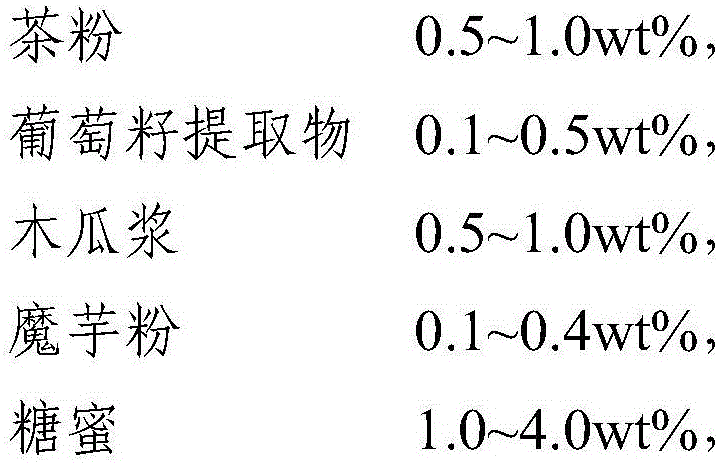

[0062] (1) Product ingredients

[0063] Add 5 grams of tea powder, 1 gram of grape seed extract, 10 grams of papaya pulp, 4 grams of konjac powder, and 40 grams of molasses into 940 grams of low-fat milk (1.0% fat, 3.2% protein) preheated to 40°C to make the material Completely dissolve and mix uniformly to obtain feed liquid;

[0064] (2) homogeneous sterilization

[0065] Preheat the feed liquid to heat up, homogenize at 60°C and 22MPa, heat and sterilize at 96°C for 90 minutes, then cool to 37°C to obtain the sterilized cooling feed liquid;

[0066] (3) Product inoculation and fermentation

[0067] Add L.plantarumST-III (2×10 6 CFU / g), L.caseiBD-II (2×10 6 CFU / g) and mannanase (2U / g), stirred for 3 minutes to mix the probiotics, mannanase and feed liquid evenly, and fermented at 37°C until the titrated acidity was 80°T to obtain fermented milk ;

[0068] (4) cooling

[0069] Cool the fermented milk to 20°C by st...

Embodiment 2

[0086] Embodiment 2 (preparation of fermented milk):

[0087] (1) Product ingredients

[0088] Add 1 gram of tea powder, 5 grams of grape seed extract, 5 grams of papaya pulp, and 1 gram of konjac powder in 978 grams of skimmed milk preheated to 50°C (restored by skimmed milk powder at a mass percentage of 12% and purified water) , 10 grams of molasses, completely dissolve the material, mix evenly, and obtain the material liquid;

[0089] (2) homogeneous sterilization

[0090] Preheat the feed liquid to heat up, homogenize at 70°C and 18MPa, heat and sterilize at 95°C for 120 minutes, then cool to 35°C to obtain the sterilized cooling feed liquid;

[0091] (3) Product inoculation and fermentation

[0092] Add L.plantarumST-III (5×10 6 CFU / g), L.caseiBD-II (5×10 6 CFU / g) and mannanase (0.5U / g), stirred for 5 minutes, so that the probiotics, mannanase and the feed liquid were mixed evenly, and at 38°C, left to ferment until the titrated acidity was 75°T, and the fermented ...

Embodiment 3

[0111] Embodiment 3 (preparation of fermented milk):

[0112] (1) Product ingredients

[0113] Add 8 grams of tea powder, 3 grams of grape seed extract, 8 grams of papaya pulp, 3 grams of konjac powder, and 30 grams of molasses into 948 grams of whole milk (fat 3.5%, protein 3.1%) preheated to 30 ° C, Stir to dissolve the material completely and mix evenly to obtain the material liquid;

[0114] (2) homogeneous sterilization

[0115] Preheat the feed liquid to heat up, homogenize at 65°C and 20 MPa, heat and sterilize at 96°C for 90 minutes, then cool to 37°C to obtain the sterilized cooling feed liquid;

[0116] (3) Product inoculation and fermentation

[0117] Add L.plantarumLPHS (5×10 6 CFU / g) and mannanase (0.8U / g), stirred for 3 minutes, so that the probiotics, mannanase and feed liquid were mixed evenly. milk;

[0118] (4) cooling

[0119] Cool the fermented milk to 18°C by stirring to obtain cooled fermented milk;

[0120] (5) Product filling and refrigerated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com