Mechanism for dissociating battery cell winding needle and needle dissociating method for mechanism

A technology of coiling needles and batteries, which is applied to circuits, electrical components, secondary batteries, etc., can solve problems such as crashing separators, positive and negative electrodes, increased maintenance, and reduced tightness of winding cores. Unable to unwind the needle normally, high degree of automation, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention and its beneficial effects will be described in further detail below in conjunction with specific embodiments and accompanying drawings, but the specific embodiments of the present invention are not limited thereto.

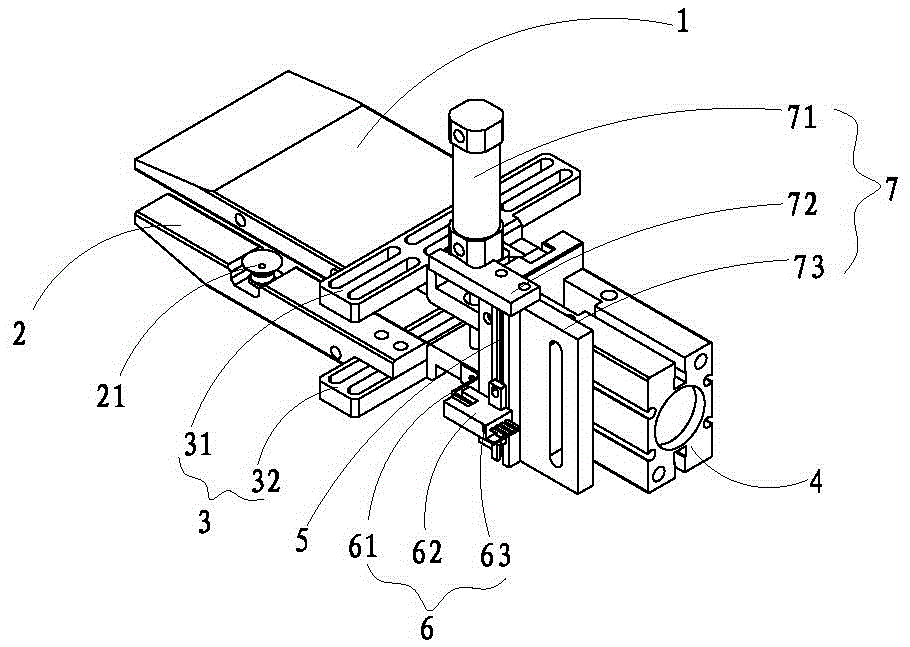

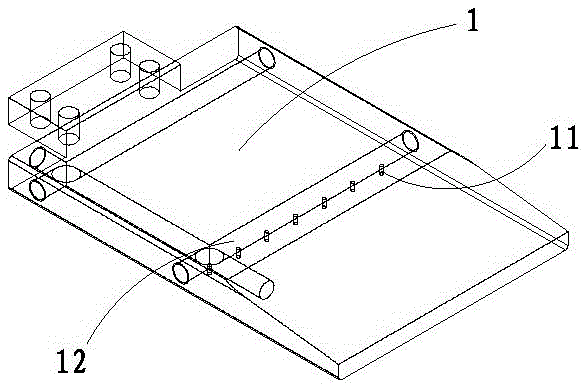

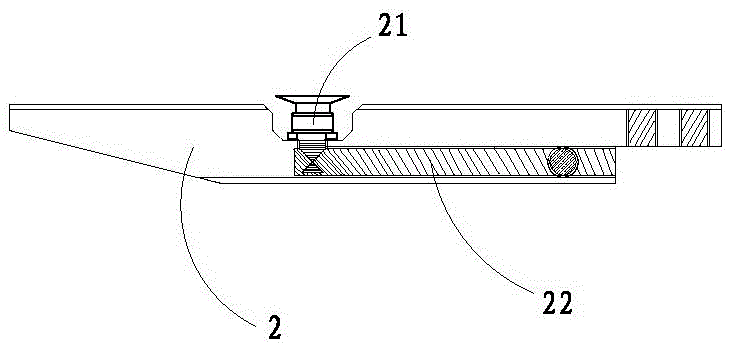

[0039] Such as Figure 1~6 As shown, a mechanism for pulling out the needle of the battery core, including a first discharge clamp 1, a second discharge clamp 2 corresponding to the first discharge clamp 1, a finger connector 3, and a finger cylinder 4. The fixed seat 5 arranged between the clamp finger connector 3 and the clamp finger cylinder 4, and the photoelectric control unit 6 and the limit control unit 7 installed on the fixed seat 5, the first discharge clamp 1, the second discharge clamp The clamps 2 are respectively connected to the clamp finger cylinder 4 through the clamp finger connector 3, the first discharge clamp 1 is provided with a vacuum suction hole 11, the second discharge clamp 2 is provided with a vacuum suctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com