Preparation method of graphene/zirconium dioxide hollow sphere/sulfur composite material

A technology of zirconium dioxide and composite materials, which is applied in the field of preparation of positive electrode materials for lithium-sulfur batteries, can solve the problems of slow migration speed, reduced utilization rate of sulfur active materials, slow electrochemical reaction kinetic speed, etc., and achieves improved electronic conductivity. efficiency and ionic conductivity, and the effect of improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

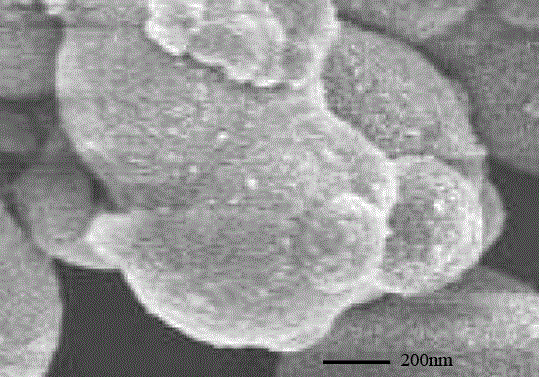

Image

Examples

Embodiment 1

[0019] (1) Weigh 100 mg of nano-calcium carbonate powder and add it to absolute ethanol, and ultrasonicate for 20 minutes to form a suspension.

[0020] (2) Weigh 200mg of zirconium oxychloride and 40mg of yttrium chloride and dissolve in 100mL of deionized water to prepare an aqueous solution.

[0021] (3) Slowly add the aqueous solution obtained in (2) into the suspension in a 90°C water bath for 3 hours, then add ammonia water to adjust the value, then add 100mg polyethylene glycol, and continue stirring the reaction mixture. After aging for a while at room temperature, a white precipitate was obtained, which was filtered, washed, and dried to obtain a white solid. After the reaction mixture was stirred for 3 hours, it was aged at room temperature for 12 hours to obtain a white precipitate, which was filtered, washed and dried to obtain a white solid.

[0022] (4) Put the obtained white solid into a muffle furnace, heat up to 500°C at a rate of 1°C / min in an air atmosphere...

Embodiment 2

[0025] (1) Weigh 100 mg of nano-calcium carbonate powder and add it to absolute ethanol, and ultrasonicate for 60 minutes to form a suspension.

[0026] (2) Weigh 20mg of zirconium oxychloride and 16mg of yttrium chloride and dissolve in 100mL of deionized water to prepare an aqueous solution.

[0027] (3) Slowly add the aqueous solution obtained in (2) into the suspension in a 90°C water bath for 5 hours, then add ammonia water to adjust the value, then add 100mg polyethylene glycol, and continue stirring the reaction mixture for 10 hours , aged at room temperature for 24 hours to obtain a white precipitate, which was filtered, washed and dried to obtain a white solid.

[0028] (4) Put the obtained white solid into a muffle furnace, raise the temperature to 550°C at a rate of 5°C / min in an air atmosphere, calcine and react for 3 hours, put it into a 10% acetic acid solution after cooling and stir React for 0.5 hours, filter, wash with water, and dry to obtain hollow zirconia...

Embodiment 3

[0031] (1) Weigh 100 mg of nano-calcium carbonate powder and add it to absolute ethanol, and ultrasonicate for 30 minutes to form a suspension.

[0032] (2) Weigh 100mg of zirconium oxychloride and 40mg of yttrium chloride and dissolve in 100mL of deionized water to prepare an aqueous solution.

[0033] (3) Slowly add the aqueous solution obtained in (2) into the suspension in a 90°C water bath for 4 hours, then add ammonia water to adjust the value, then add 100mg polyethylene glycol, and continue stirring the reaction mixture for 6 hours , aged at room temperature for 15 hours to obtain a white precipitate, which was filtered, washed and dried to obtain a white solid.

[0034] (4) Put the obtained white solid into a muffle furnace, raise the temperature to 525°C at a rate of 3°C / min in an air atmosphere, calcine and react for 5 hours, put it into a solution with a volume concentration of 6% after cooling, and stir for reaction After 4 hours, filter, wash with water, and dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com