Environment-friendly board, floor and laminated board

An environment-friendly, board-based technology, applied to floors, coverings/linings, buildings, etc., can solve problems such as high production costs, difficult forming of bamboo charcoal boards, complicated processing technology, etc., and achieve the effect of simple production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

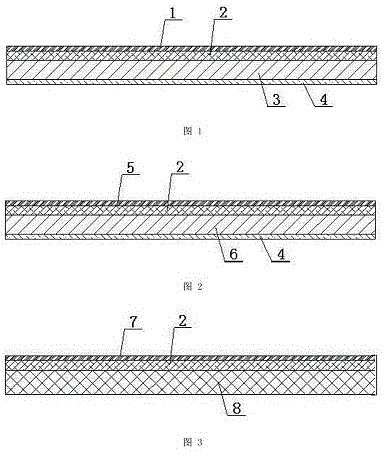

[0041] Such as figure 1 The shown environment-friendly floor comprises from top to bottom: corium layer 1, bamboo charcoal resin composite material adsorption layer 2, plank layer 3 and bamboo charcoal resin composite material waterproof material layer 4; each layer of material is bonded by adhesive, And molded into one, the base material of the adhesive can be selected from one of phenolic resin, urea-formaldehyde resin or epoxy resin, the adhesive of bamboo charcoal particles is dispersed in the adhesive matrix material, the particle size of bamboo charcoal particles More than 200 mesh. The thickness of above-mentioned corium layer 1 is 1.2mm, and the surface molding of corium layer 1 is provided with antiskid pattern, the thickness of adsorption layer 2 is 1.5mm, the thickness of plank layer 3 is 3mm, and the thickness of waterproof material layer 4 is 2mm.

Embodiment 2

[0043] Such as figure 2 Shown environment-friendly floor, this floor comprises from top to bottom: bamboo charcoal cortex 5, bamboo charcoal resin composite material adsorption layer 2, plywood 6 and bamboo charcoal resin composite material waterproof material layer 4; Each layer of material is bonded by adhesive, and Molded into one, the base material of the adhesive can be selected from one of phenolic resin, urea-formaldehyde resin or epoxy resin, and the adhesive of bamboo charcoal particles is dispersed in the adhesive matrix material, and the particle size of bamboo charcoal particles is larger than 200 mesh. The thickness of bamboo charcoal cortex 5 is 1.2mm, and the surface molding of bamboo charcoal cortex 5 is provided with anti-slip pattern, and the thickness of adsorption layer 2 is 1.5mm, and the thickness of plywood 6 is 3mm, and the thickness of waterproof material layer 4 is 2mm.

Embodiment 3

[0045] Such as image 3 The environment-friendly veneer as shown, the veneer includes from top to bottom: carbon skin layer 7, bamboo charcoal resin composite material adsorption layer 2, plastic plate layer 8; each layer of material is bonded by adhesive, and molded into one, so The matrix material of described adhesive can be selected a kind of in phenolic resin, urea-formaldehyde resin or epoxy resin, is dispersed with the adhesive of bamboo charcoal particle in the adhesive matrix material, and the granularity of bamboo charcoal particle is greater than 200 orders. The thickness of the carbon skin layer 7 is 1.2 mm, the surface of the carbon skin layer 7 is molded with decorative patterns, the thickness of the adsorption layer 2 is 1.5 mm, and the thickness of the plastic plate layer 8 is 5 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com