Preparation method for copper surface corrosion inhibition assembled membrane

A copper surface and corrosion inhibition technology, applied in the direction of metal material coating process, etc., can solve the problem of easy corrosion of copper surface, and achieve the effect of inhibiting corrosion, reducing cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] After polishing the surface of the copper electrode with metallographic sandpaper of different meshes, rinse with absolute ethanol and deionized water to remove surface oil and grease.

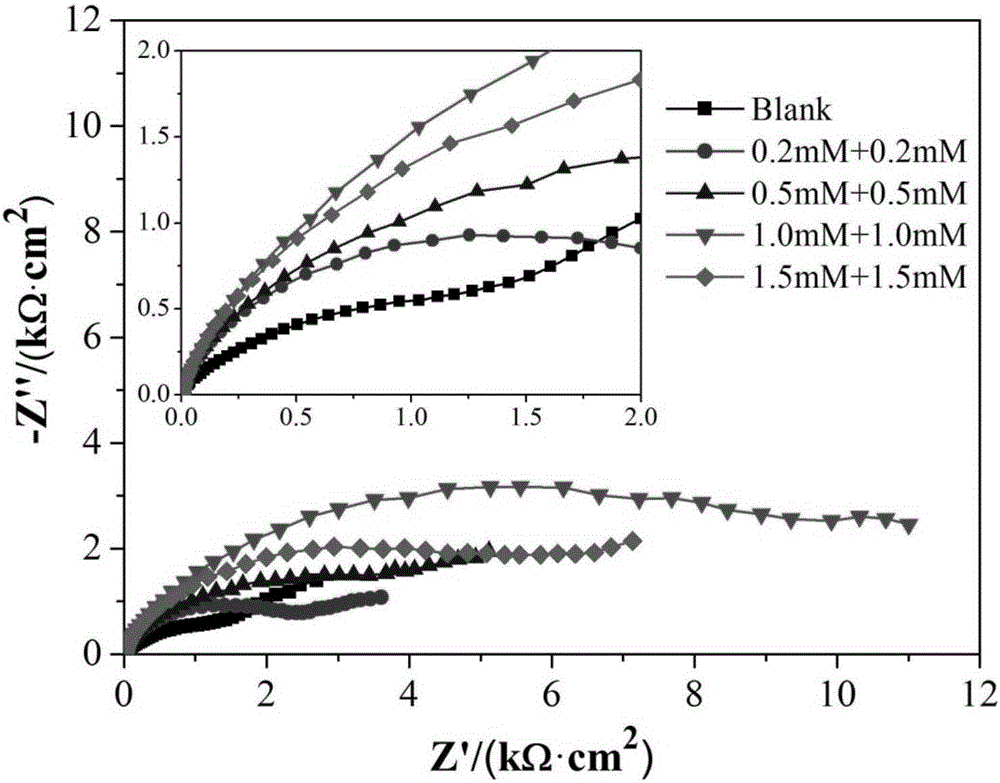

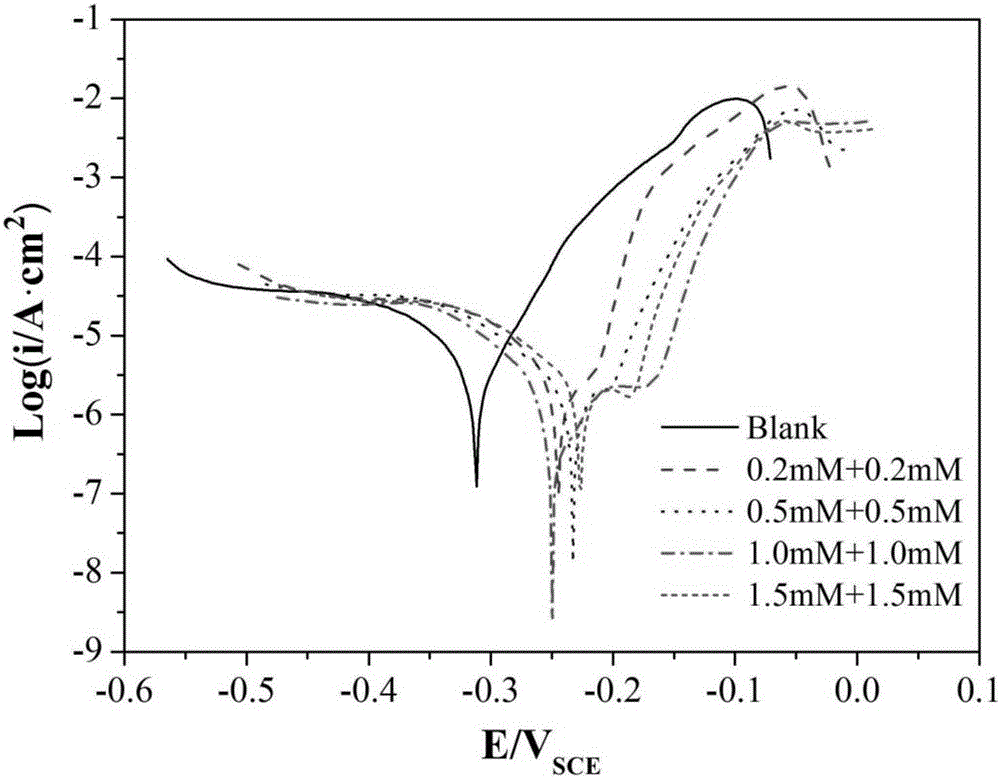

[0029] The pretreated copper electrode was assembled in 2-methyl-3-butyn-2-ol concentration of 0.2mM, 0.5mM, 1.0mM, 1.5mM ethanol solution for 1h, and then correspondingly in p-toluenesulfonyl azide Click and assemble in ethanol solutions with nitrogen concentrations of 0.2mM, 0.5mM, 1.0mM, and 1.5mM for 30min. After the click assembly is completed, rinse with water and dry to obtain a uniform triazole corrosion-inhibiting film on the copper surface.

Embodiment 2

[0039] After polishing the surface of the copper electrode with metallographic sandpaper of different meshes, rinse with absolute ethanol solution and deionized water to remove surface oil and grease.

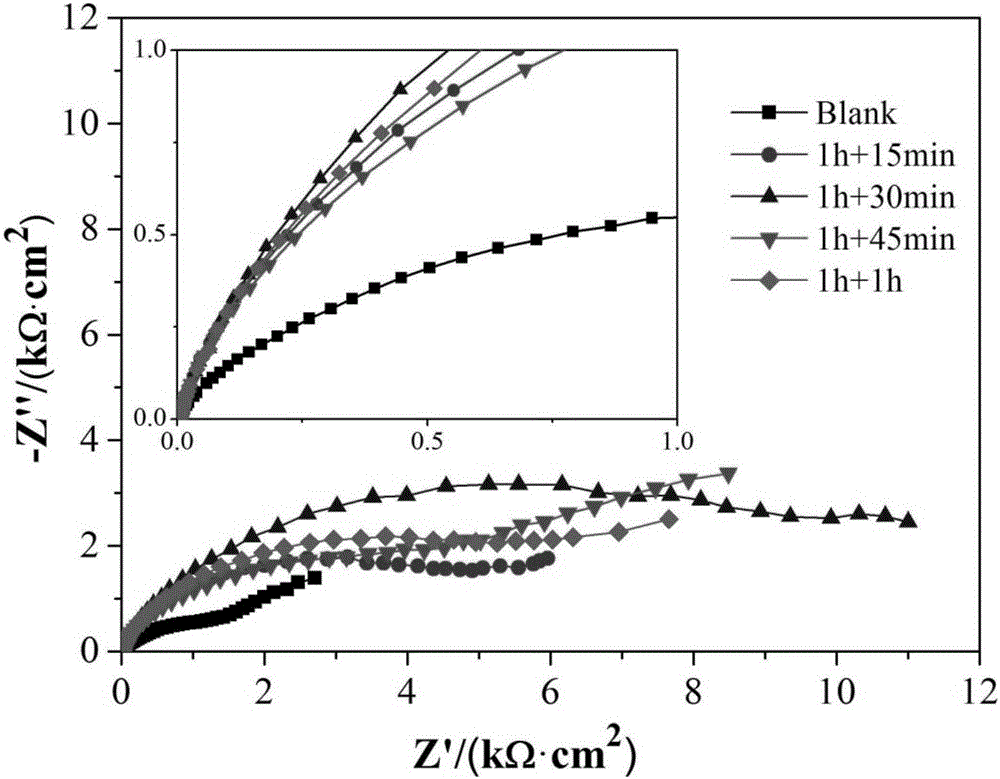

[0040] The pretreated copper electrode was assembled in an ethanol solution with a concentration of 1.0mM of 2-methyl-3-butyn-2-ol for 1h, and then correspondingly in an ethanol solution with a concentration of p-toluenesulfonyl azide of 1.0mM Click to assemble 15min, 30min, 45min, 1h. After the click assembly is completed, rinse with water and dry to obtain a uniform triazole corrosion-inhibiting film on the copper surface.

Embodiment 3

[0049] After polishing the surface of the copper electrode with metallographic sandpaper of different meshes, rinse with absolute ethanol solution and deionized water to remove surface oil and grease.

[0050] The pretreated copper sheets were assembled in an ethanol solution with a concentration of 1.0mM of 2-methyl-3-butyn-2-ol for 1h, and then correspondingly in an ethanol solution with a concentration of p-toluenesulfonyl azide of 1.0mM Click to assemble for 30 minutes. After the click assembly is completed, rinse with water and dry to obtain a uniform triazole corrosion-inhibiting film on the copper surface. Measure the diffuse reflection result of the copper surface after clicking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com