Method used for producing hydrogen by taking cellulose as raw material

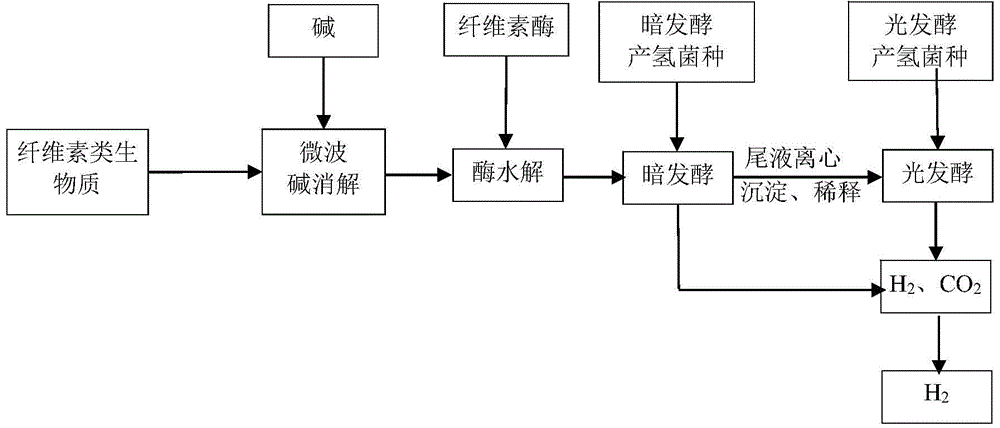

A cellulose and cellulose-based technology, applied in the field of biomass energy production, can solve the problems of impossible breakthrough in hydrogen production efficiency, unfavorable technology promotion and application, difficult control of microwave oven temperature and pressure, and reduce detoxification. and other processes, improve the efficiency of cellulose degradation and the effect of fast heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Example 1: Using rice straw to produce hydrogen

[0080] (1) Microwave alkali digestion: the dry weight of the dry weight of the cellulose biomass and the mass ratio of the sodium hydroxide solution are as follows: Mix at a ratio of 2:100, pressurize and heat for 15 minutes in a microwave heating and digestion apparatus at 140°C and a pressure of 0.2-0.7MPa.

[0081](2) Enzymatic hydrolysis: use 6mol / L hydrochloric acid to adjust the pH of the digestion solution obtained in step (1) to 4.5, and in the digestion solution according to the mass ratio of cellulase and the dry weight of cellulosic biomass to 4:100 Cellulase was added for enzymatic hydrolysis at 45°C for 84 hours. The reducing sugar concentration in the solution after enzymolysis was determined (Table 1).

[0082] (3) Hydrogen production by dark fermentation: add the solution after step (2) enzymatic hydrolysis into the dark fermentation reactor, add the dark fermentation medium according to the volume rati...

Embodiment 2

[0086] Example 2: Production of hydrogen from corn stalks

[0087] (1) Microwave alkali digestion: the dried and pulverized corn stalks (particle diameter≤1mm) and the potassium hydroxide solution with a concentration of 2.0wt% are according to the mass ratio of the dry weight of the cellulosic biomass to the potassium hydroxide solution: Mix at a ratio of 4:100, pressurize and heat for 20 minutes in a microwave heating and digestion apparatus at 145°C and a pressure of 0.2-0.76MPa.

[0088] (2) Enzymatic hydrolysis: use 6mol / L dilute sulfuric acid to adjust the pH of the digestion solution obtained in step (1) to 4.8, and use 3:100 in the digestion solution according to the mass ratio of cellulase and the dry weight of cellulosic biomass Cellulase was added to the medium, and the enzymatic hydrolysis was carried out at 40°C for 96 hours.

[0089] (3) Hydrogen production by dark fermentation: add the solution after step (2) enzymatic hydrolysis into the dark fermentation reac...

Embodiment 3

[0093] Example 3: Production of hydrogen from wheat straw

[0094] (1) Microwave alkali digestion: dry and pulverize wheat straw (particle size≤1mm) and ammonia solution with a concentration of 3.0wt% according to the mass ratio of the dry weight of cellulosic biomass to the ammonia solution is 5:100 Proportionally mixed, pressurized and heated for 10 minutes in a microwave heating digestion apparatus at 135° C. and a pressure of 0.2 to 0.6 MPa.

[0095] (2) Enzymatic hydrolysis: use 6mol / L phosphoric acid to adjust the pH of the digestion solution obtained in step (1) to 4.2, and in the digestion solution according to the mass ratio of cellulase and the dry weight of cellulosic biomass is 2.5:100 Cellulase was added for enzymatic hydrolysis at 39°C for 84 hours.

[0096] (3) Hydrogen production by dark fermentation: add the solution after step (2) enzymatic hydrolysis into the dark fermentation reactor, add the dark fermentation medium according to the volume ratio of the da...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com