Method for producing high-specific-capacity shuttlelike copper oxide electrode material

A copper oxide and shuttle-shaped technology, applied in hybrid capacitor electrodes, copper oxide/copper hydroxide, nanotechnology, etc., can solve the problems of limited use, high cost, toxicity, etc., and achieve narrow particle size distribution, broad application prospects, highly responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

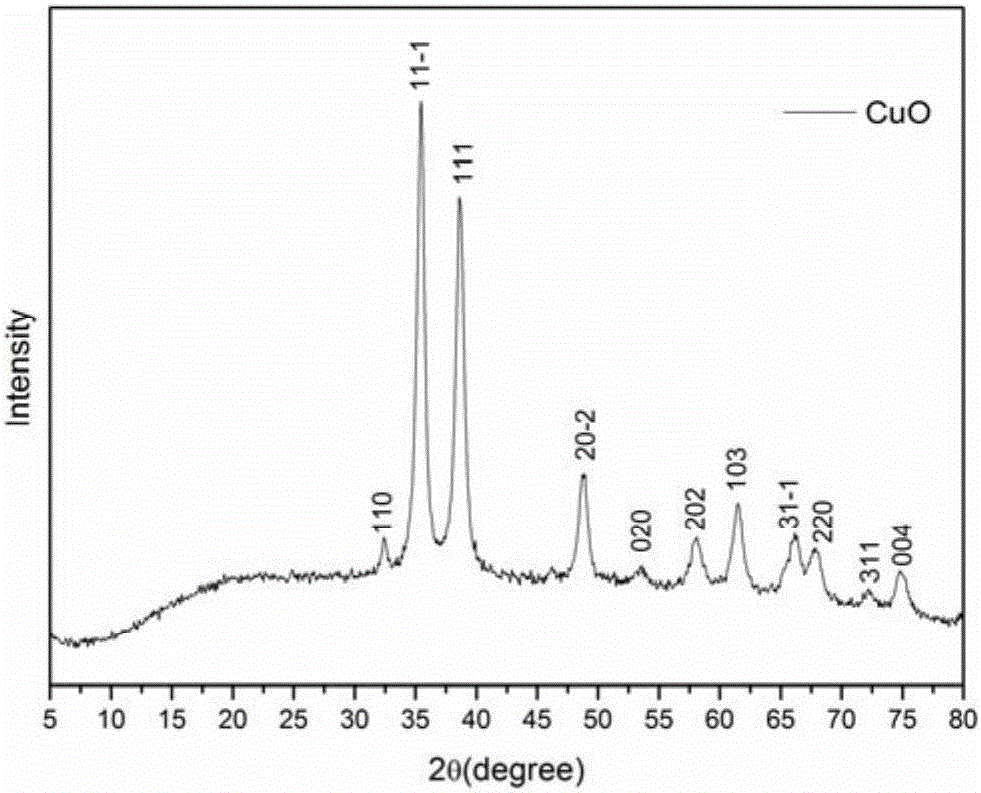

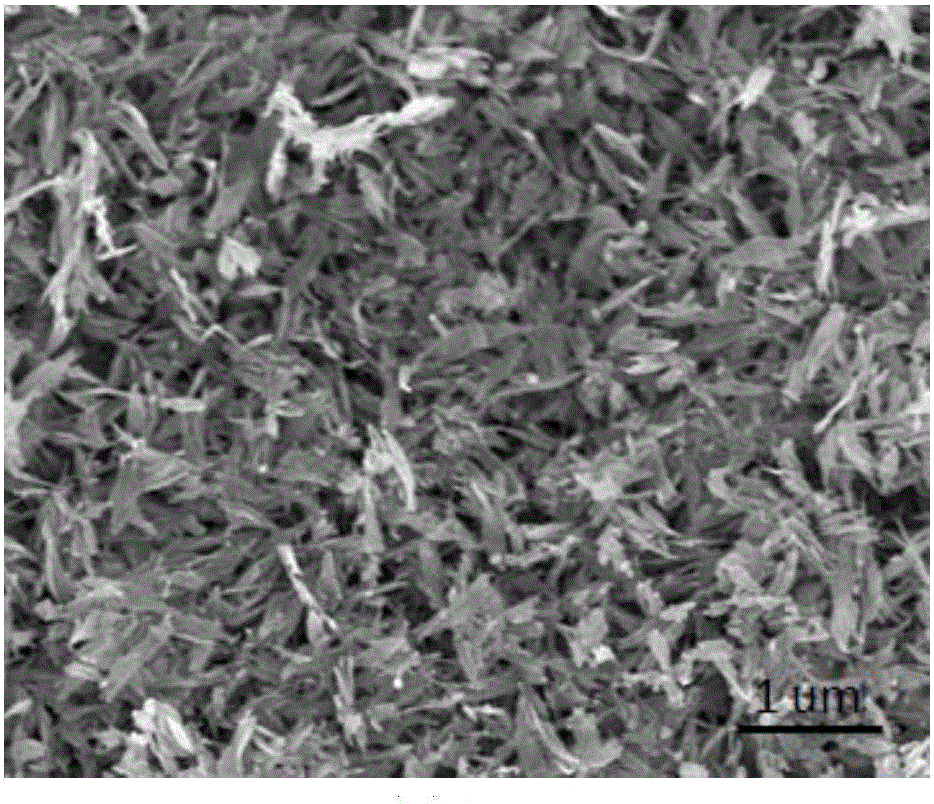

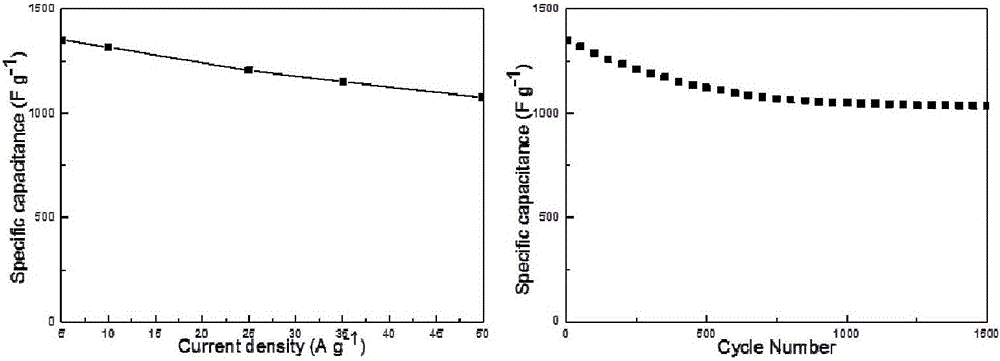

[0035] First need to weigh 1mmol CuCl 2 , into a 50mL beaker, then add 40mL deionized water, stir, then add 1mmolNa 2 CO 3 and 1mL of triethylamine solution, stirred for 10 minutes, then ultrasonicated for 5 minutes, and then directly put into the microwave oven, set the power to 300W, and the time was 20 minutes, and washed several times with deionized water and absolute ethanol, and then in Dry in an oven at 60°C for 6 hours to obtain a copper oxide nanoshuttle sample. Such as figure 1 Shown product is identified as copper oxide through X-ray powder diffraction; Carry out morphology analysis to copper oxide with scanning electron microscope (SEM), from figure 2 It can be seen that its morphology is nanoshuttle. Excellent electrochemical cycle performance and specific capacitance can be obtained from image 3 see.

Embodiment 2

[0037] First need to weigh 1mmol CuCl 2 , into a 50mL beaker, then add 40mL deionized water, stir, then add 1mmolNa 2 CO 3 and 1mL of triethylamine solution, stirred for 10 minutes, then ultrasonicated for 5 minutes, and then directly put into the microwave oven, set the power to 200W, and the time was 20 minutes, and washed several times with deionized water and absolute ethanol, and then in Dry in an oven at 60°C for 6 hours to obtain a copper oxide nanoshuttle sample. The morphology of copper oxide was analyzed by transmission electron microscopy (TEM). Figure 4 It can be seen that its morphology is nanoshuttle.

Embodiment 3

[0039] First need to weigh 1mmol CuCl 2 , into a 50mL beaker, then add 40mL deionized water, stir, then add 1mmolNa 2 CO 3 and 1mL of triethylamine solution, stirred for 10 minutes, then ultrasonicated for 5 minutes, and then directly put into the microwave oven, set the power to 400W, and the time was 20 minutes, and washed several times with deionized water and absolute ethanol, and then in Dry in an oven at 60°C for 6 hours to obtain a copper oxide nanoshuttle sample. The morphology of copper oxide was analyzed by transmission electron microscopy (TEM). Figure 5 It can be seen that its morphology is nanoshuttle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com