Preparation method of magnetic activated carbon

A technology of magnetic activated carbon and bamboo chips, which is applied in the field of activated carbon, can solve the problems of reduced adsorption capacity of activated carbon, pore blocking effect of activated carbon, low magnetic strength of activated carbon, etc., and achieves the effects of convenient operation, less production equipment and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

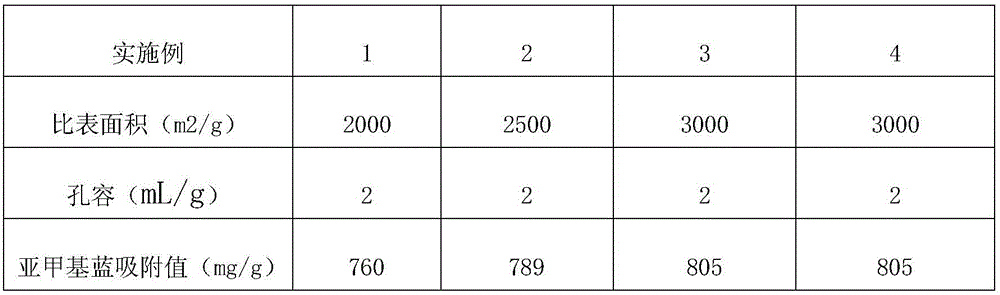

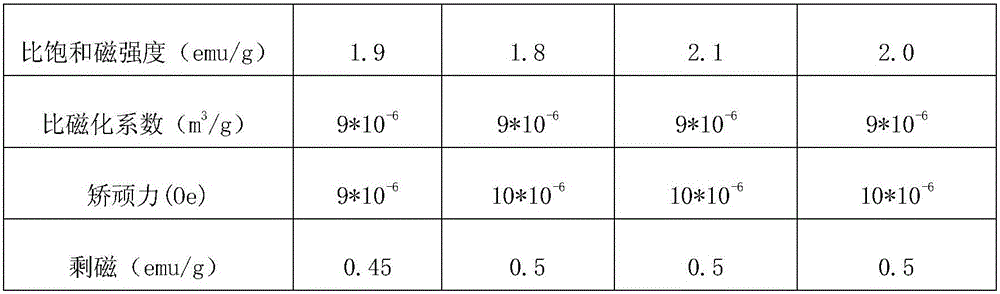

Examples

Embodiment 1

[0012] A preparation method for magnetic activated carbon, comprising the steps of:

[0013] 1) Take bamboo chips, lauric acid, K 2 CO 3 , FeSO 4 ·7H 2 O, H 2 o 2 Mix with water at a certain mass ratio of 1:0.1:10:10:10:100, immerse for 12 hours after ultrasonication for 0.5 hours, and dry to obtain mixture A;

[0014] 2) Microwave heating: move the mixture A to a high-pressure reactor with a pressure of 0.01mPa, then place the reactor in a microwave oven with a power of 1000w, and heat for 60s to obtain a mixture B;

[0015] 3) Filtration and drying: the mixture B was filtered in a filter with a 0.2um PTFE membrane, and the obtained filter cake was dried at a temperature of 80° C. for 200 minutes to obtain magnetic activated carbon.

Embodiment 2

[0017] A preparation method for magnetic activated carbon, comprising the steps of:

[0018] 1) Take bamboo chips, lauric acid, K 2 CO 3 , FeSO 4 ·7H 2 O, H 2 o 2 Mix with water at a certain mass ratio of 1:0.5:50:50:50:500, immerse for 24 hours after ultrasonication for 2 hours, and dry to obtain mixture A;

[0019] 2) Microwave heating: move the mixture A to a high-pressure reactor with a pressure of 0.05mPa, then place the reactor in a microwave oven with a power of 200w, and heat for 200s to obtain a mixture B;

[0020] 3) Filtration and drying: the mixture B is filtered in a filter with a 0.2um PTFE membrane, and the obtained filter cake is dried at a temperature of 150° C. for 20 minutes to obtain magnetic activated carbon.

Embodiment 3

[0022] A preparation method for magnetic activated carbon, comprising the steps of:

[0023] 1) Take bamboo chips, lauric acid, K 2 CO 3 , FeSO 4 ·7H 2 O, H 2 o 2 Mix with water at a certain mass ratio of 1:0.1:50:50:10:500, immerse for 12 hours after ultrasonication for 0.5 hours, and dry to obtain mixture A;

[0024] 2) Microwave heating: move mixture A to a high-pressure reactor with a pressure of 0.02mPa, then place the reactor in a microwave oven with a power of 500w, and heat for 100s to obtain mixture B;

[0025] 3) Filtration and drying: the mixture B is filtered in a filter with a 0.2um PTFE membrane, and the obtained filter cake is dried at a temperature of 100° C. for 100 minutes to obtain magnetic activated carbon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com