Lithium battery electrode preparation method including polymer material with stable interface and application of lithium battery electrode in solid lithium battery

A technology of polymer materials and interface stabilization, which is applied in battery electrodes, lithium batteries, secondary batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Add AIBN to VCA under argon protection, the mass fraction of AIBN is 0.1%; 40 o C temperature, stirring for 24 hours, to obtain PVCA polymer; PVCA polymer was dissolved in DMF, made into a 2wt.% solution. Preparation of LiFePO for Lithium Batteries Using PVCA Polymer as Binder 4 Electrode pole piece, the mass fraction of binder is 10%; LiFePO 4 The electrode pole piece is immersed in the PVCA solution for 1 minute and then taken out; at 60 o C under vacuum drying for 24 hours to ensure that the solvent has been completely volatilized to obtain PVCA polymer-coated LiFePO 4 Electrode pads.

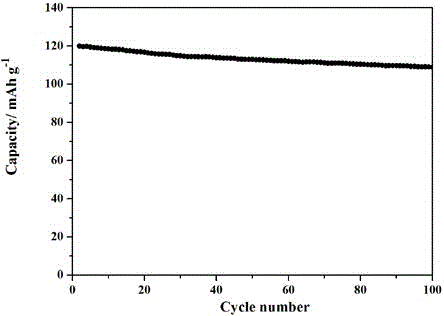

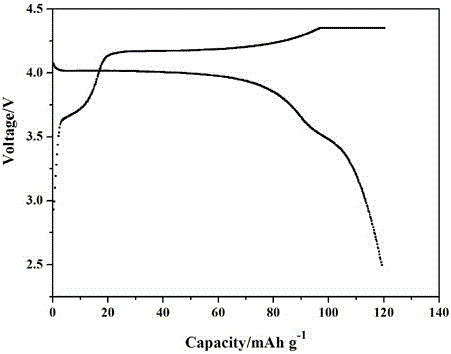

[0035] The materials used to prepare and assemble lithium-ion batteries are shown in Table 1. The negative pole is uncoated metal lithium, and the solid electrolyte is PVCA / LiDFOB all-solid electrolyte obtained by in-situ polymerization. The first charge specific capacity of the prepared ion battery is 122mAhg -1 , the first discharge specific capacity is 119mAhg -1 , the first C...

Embodiment 2

[0039] Add BPO in the VCA under argon protection, the mass fraction of BPO is 0.5%; 80 o C temperature, stirring for 2 hours, to obtain PVCA polymer; PVCA polymer was dissolved in DMF, made into a 5wt.% solution. Using PVCA polymer as a binder to prepare graphite electrode pole pieces for lithium batteries, the mass fraction of the binder is 5%; the graphite electrode pole piece is immersed in PVCA solution for 5 minutes and then taken out; at 60 o C under vacuum drying for 24 hours to ensure that the solvent has been completely volatilized to obtain a PVCA polymer-coated graphite electrode pole piece.

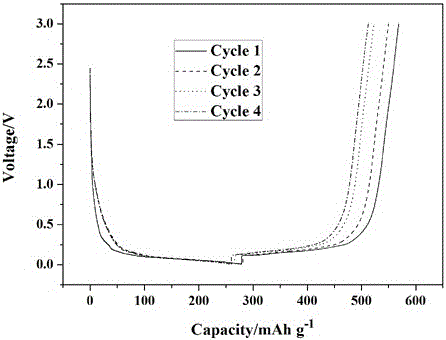

[0040] The materials used to prepare and assemble lithium-ion batteries are shown in Table 1. The reference electrode is uncoated lithium metal, and the solid electrolyte is PVCA / LiTFSI all-solid electrolyte obtained by in-situ polymerization. The first charge specific capacity of the prepared ion battery is 336mAhg -1 , the first discharge specific capacity is 289mAhg -1 ,...

Embodiment 3

[0044] Add AIBN to VCA under argon protection, the mass fraction of AIBN is 1%; 60 o C temperature, stirring for 12 hours, to obtain PVCA polymer; PVCA polymer was dissolved in DMF, made into a 20wt.% solution. Preparation of LiFe for Lithium Batteries Using PVCA Polymer as Binder 0.2 mn 0.8 PO 4 Electrode pole piece, the mass fraction of binder is 20%; LiFe 0.2 mn 0.8 PO 4 The electrode pole piece is immersed in the PVCA solution for 1 minute and then taken out; at 60 o C under vacuum drying for 24 hours to ensure that the solvent has been completely volatilized to obtain PVCA polymer-coated LiFe 0.2 mn 0.8 PO 4 Electrode pads. Using PVCA polymer as a binder to prepare graphite electrode pole pieces for lithium batteries, the mass fraction of the binder is 5%; the graphite electrode pole piece is immersed in PVCA solution for 2 minutes and then taken out; at 60 o C under vacuum drying for 24 hours to ensure that the solvent has been completely volatilized to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com