Thin film transistor, array substrate, production method of thin film transistor and display device

A technology for thin film transistors and a manufacturing method, which is applied to transistors, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of low production efficiency, many times of using masks, etc., to simplify the production process, save production costs, The effect of reducing the number of compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

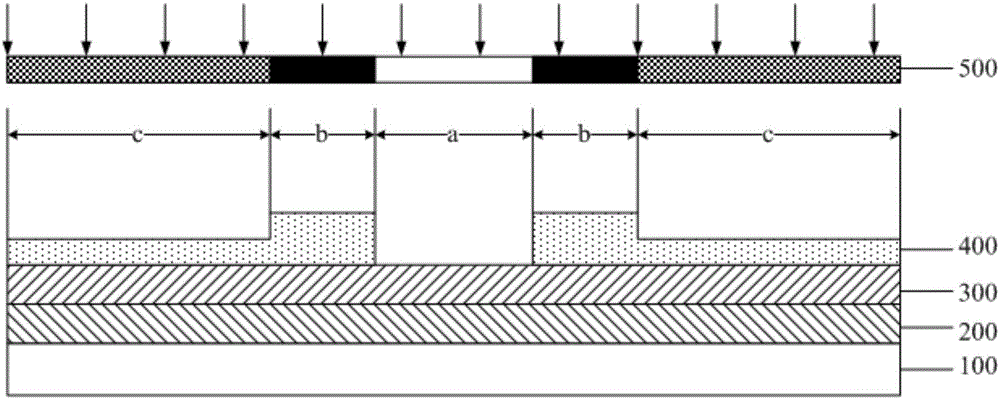

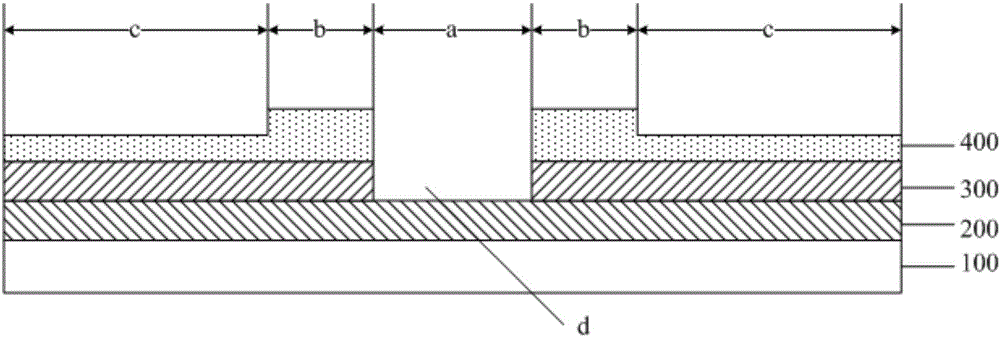

[0045] The specific implementation manners of the thin film transistor, the array substrate, the manufacturing method thereof, and the display device provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0046] The film thicknesses of various layers and the shapes and sizes of the regions in the drawings do not reflect the true proportions of the thin film transistors, but are only intended to schematically illustrate the content of the present invention.

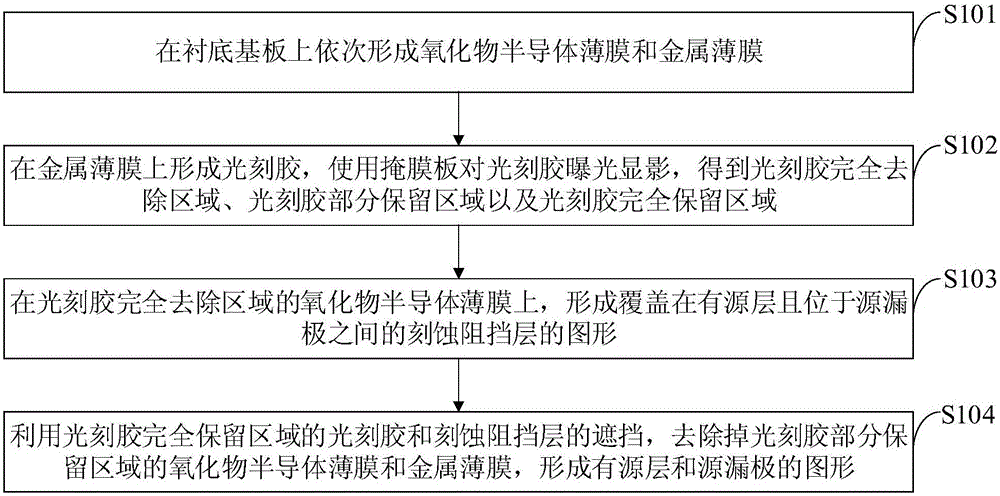

[0047] A method for manufacturing a thin film transistor provided by an embodiment of the present invention includes the following steps: forming patterns of an active layer, source and drain electrodes, and an etch barrier layer on a base substrate through a patterning process, and the etch barrier layer covers The active layer is located between the source and drain electrodes.

[0048] In the manufacturing method of the above-mentioned thin f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com