Manufacturing method of array substrate, array substrate and display device

A manufacturing method and array substrate technology, applied in semiconductor/solid-state device manufacturing, instruments, semiconductor devices, etc., can solve problems such as increasing production costs and reducing production efficiency, and achieve the effects of improving manufacturing efficiency, preventing short circuits, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

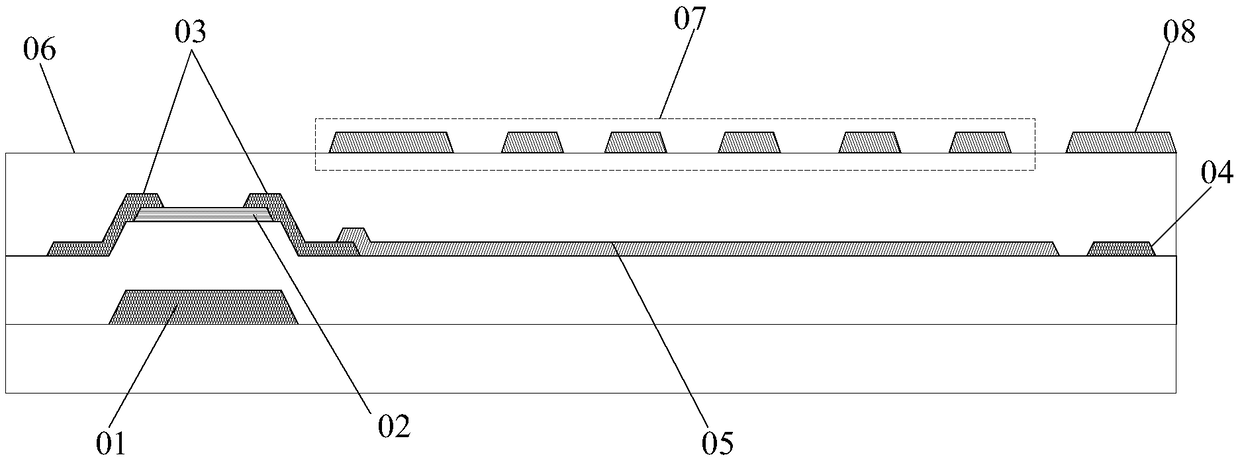

[0050] The method for fabricating the array substrate, the implementation of the array substrate and the display device provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0051] The thickness and area size and shape of each layer of film in the drawings do not reflect the real proportion of the array substrate, but are only intended to schematically illustrate the content of the present invention.

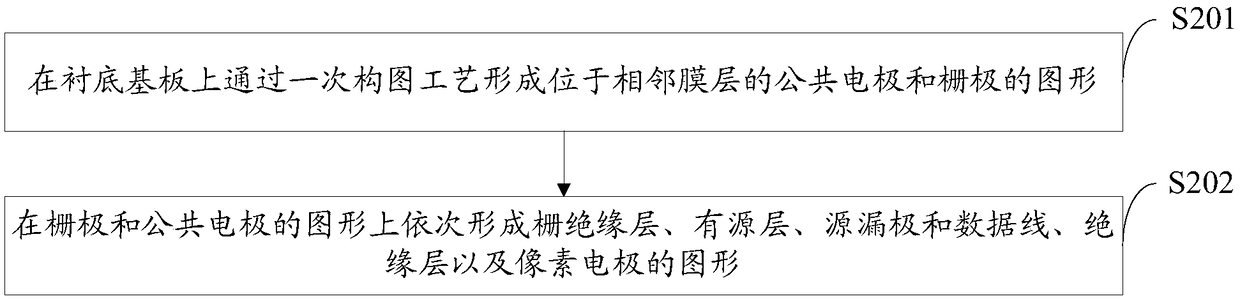

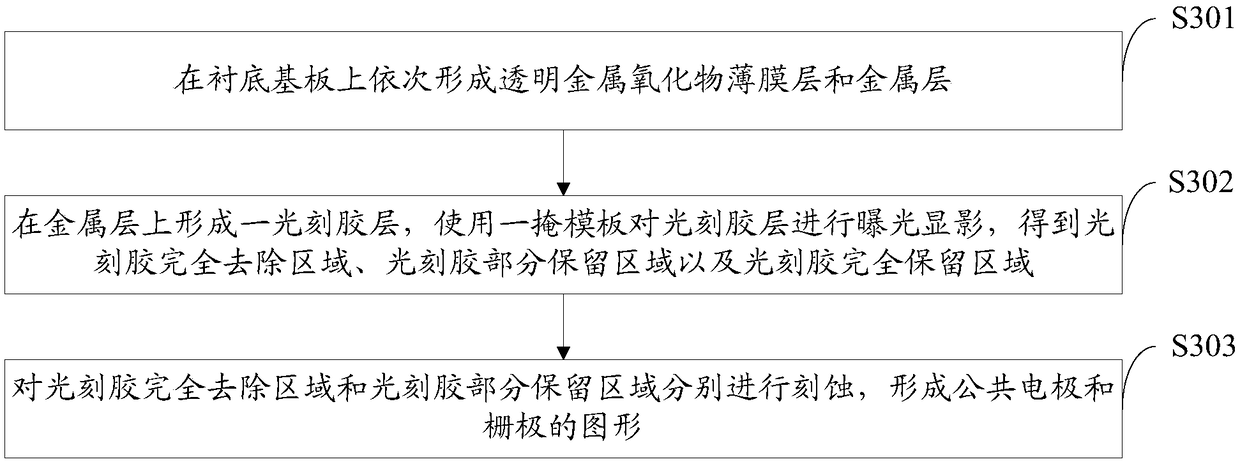

[0052] An embodiment of the present invention provides a method for manufacturing an array substrate, such as figure 2 As shown, it specifically includes the following steps:

[0053] S201, forming patterns of common electrodes and gates located in adjacent film layers on the base substrate through a patterning process;

[0054] S202, sequentially forming a pattern of a gate insulating layer, an active layer, a source / drain electrode, a data line, an insulating layer, and a pixel electrode on the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com