Array substrate, manufacturing method thereof, and display device

An array substrate, primary color technology, applied in instruments, semiconductor devices, optics, etc., can solve the problems of many patterning times and complex processes, and achieve the effects of high contrast, lower cost, and reduced patterning times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

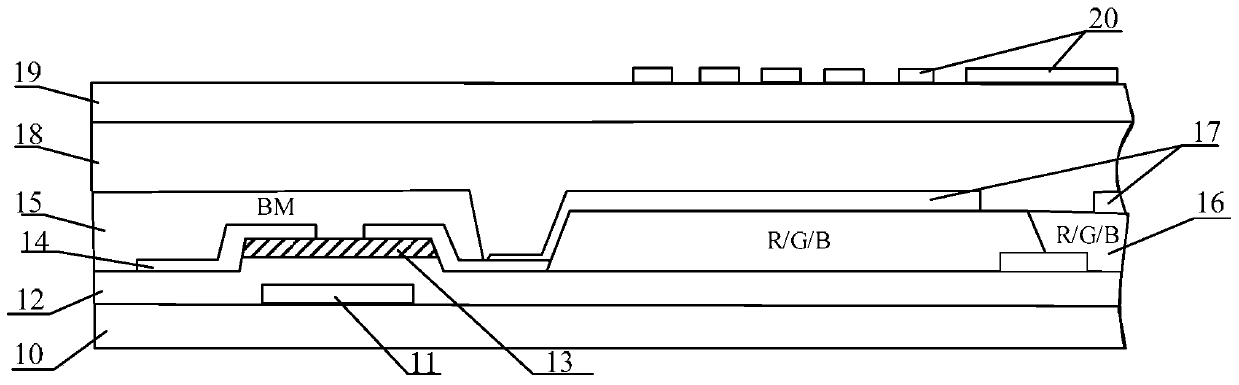

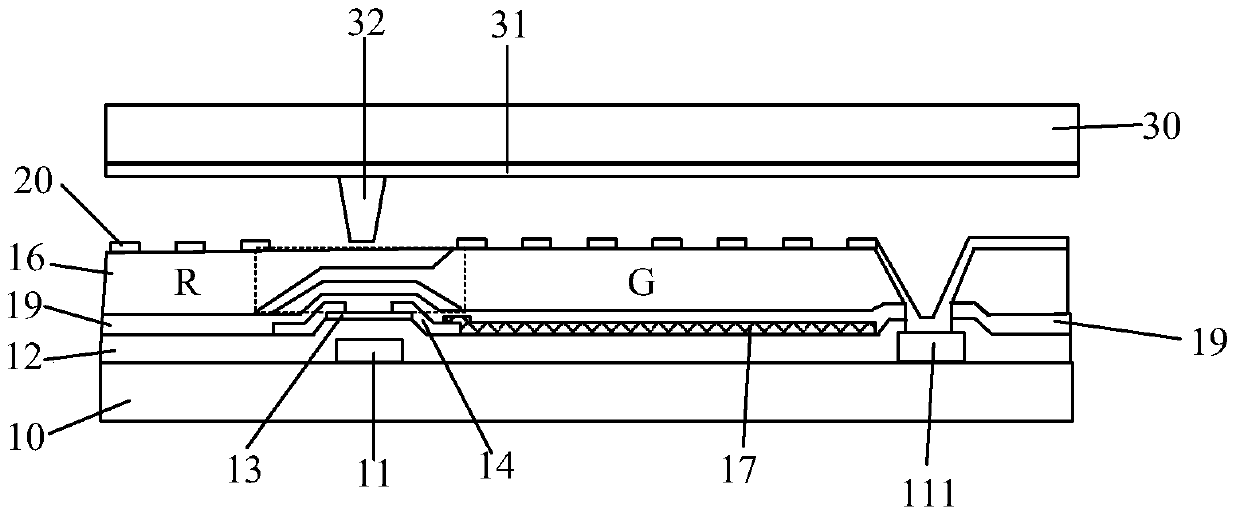

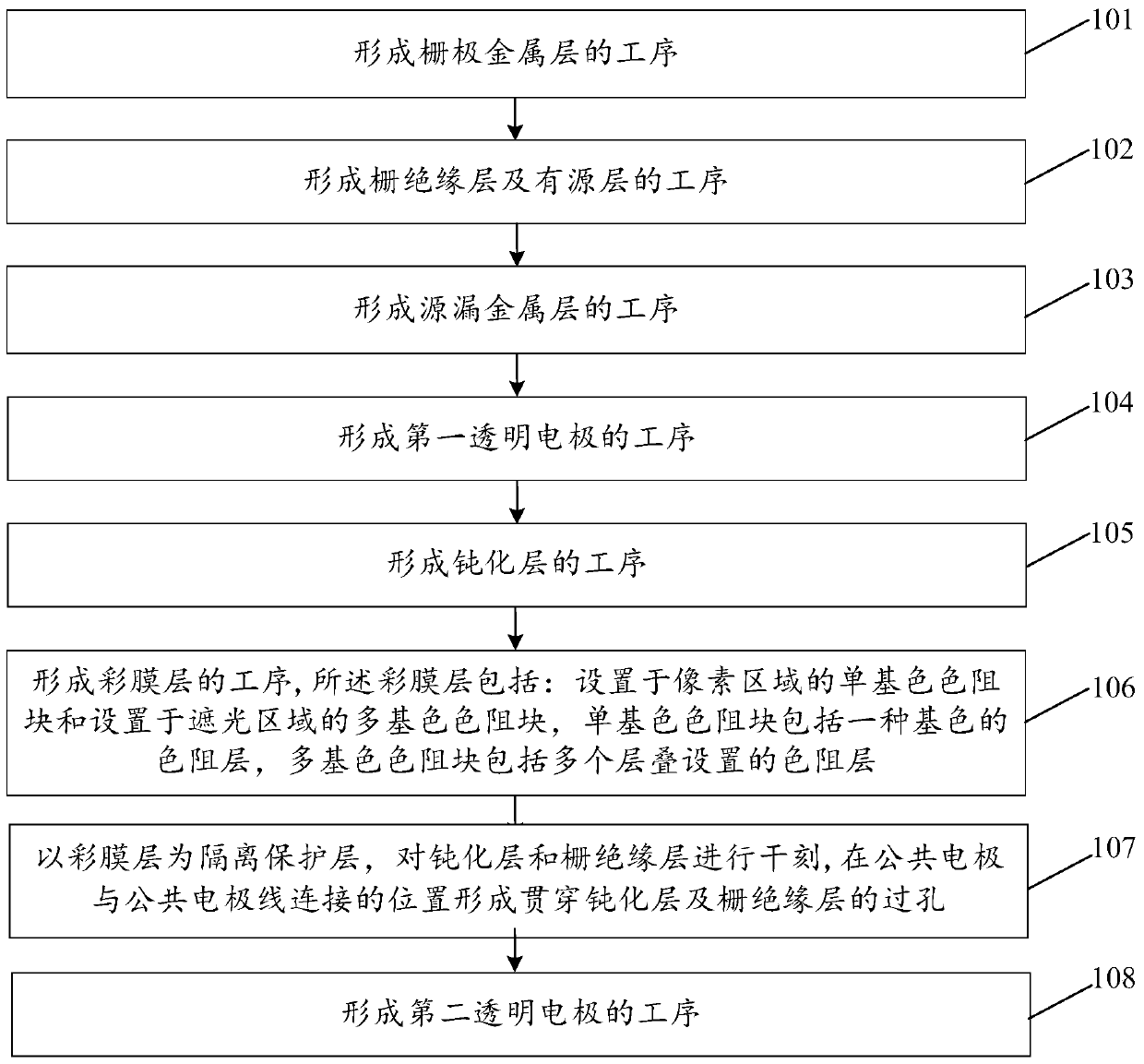

[0033] Embodiments of the present invention provide a method for preparing an array substrate, an array substrate, and a display device, which can fabricate a color filter on the array substrate, reduce the number of patterning times, and reduce costs.

[0034] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0035] An embodiment of the present invention provides an array substrate, including: a thin film transistor and a color filter layer disposed on the thin film transistor, and the color filter layer includes: a single-color color-resist block disposed in the pixel area and a color filter block disposed in the light-shielding area The multi-primary-color color-resist block, the single-primary-color color-resist block includes a color-resist layer of one primary color, the multi-primary-color color-resist block includes a plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com