Manufacturing method for touch screen

A production method and touch screen technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problems of low production efficiency and many times of mask plates, so as to improve manufacturing efficiency, reduce production cost, The effect of reducing the number of frames

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

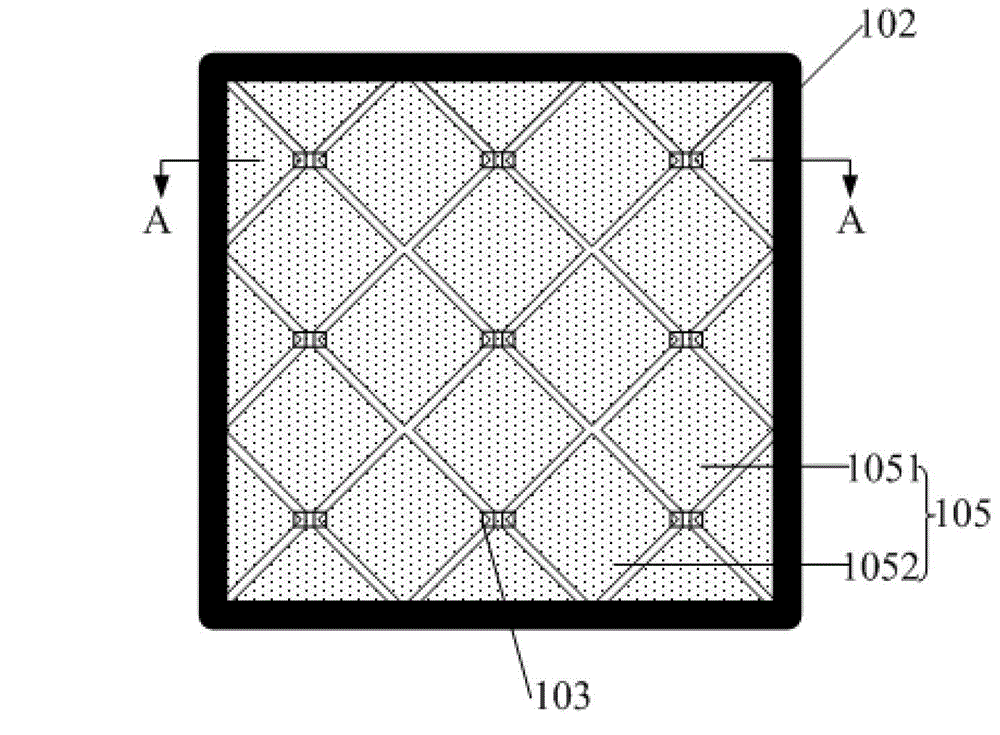

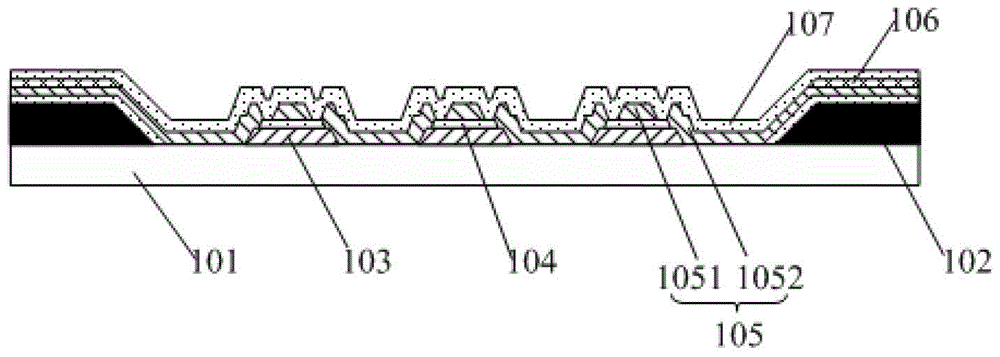

[0022] The specific implementations of the touch screen, the manufacturing method thereof, and the display device provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0023] The thickness of each layer and the size and shape of the regions in the drawings do not reflect the real scale, and are only intended to illustrate the content of the present invention.

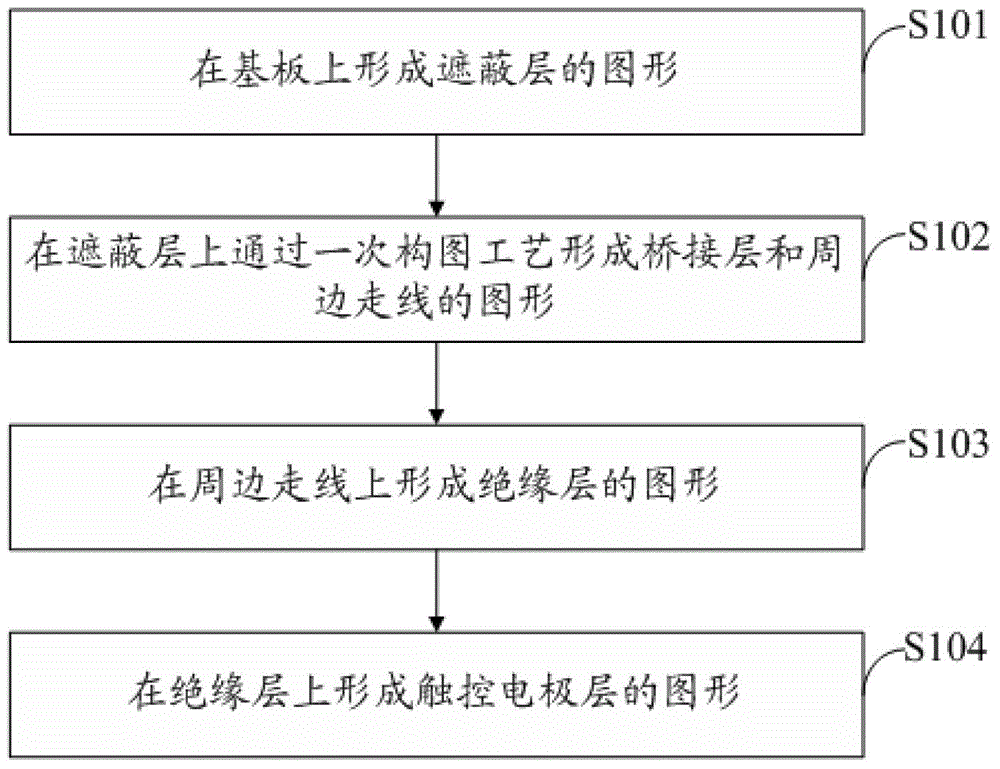

[0024] An embodiment of the present invention provides a method for manufacturing a single touch screen, such as figure 2 It includes the following steps:

[0025] Step S102 , a pattern of the bridge layer 3 and the peripheral wiring 4 is formed on the substrate 1 through a patterning process, such as Figure 3b As shown, the peripheral traces 4 only have graphics in the non-touch area B of the touch screen, and the bridge layer 3 has graphics in both the touch area A and the non-touch area B;

[0026] Preferably, before performing step S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com