A device and method for treating hazardous waste from low-zinc-containing steelmaking and producing nano-zinc oxide

A technology of nano-zinc oxide and coarse zinc oxide, which is applied in resource utilization, high-tech treatment of hazardous waste, low-zinc-containing steelmaking hazardous waste treatment and production of nano-zinc oxide, harmless field, can solve hazardous waste, Unrecyclable, poor practicability and other problems, to achieve the effects of reducing production costs, improving production efficiency, and significant novelty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

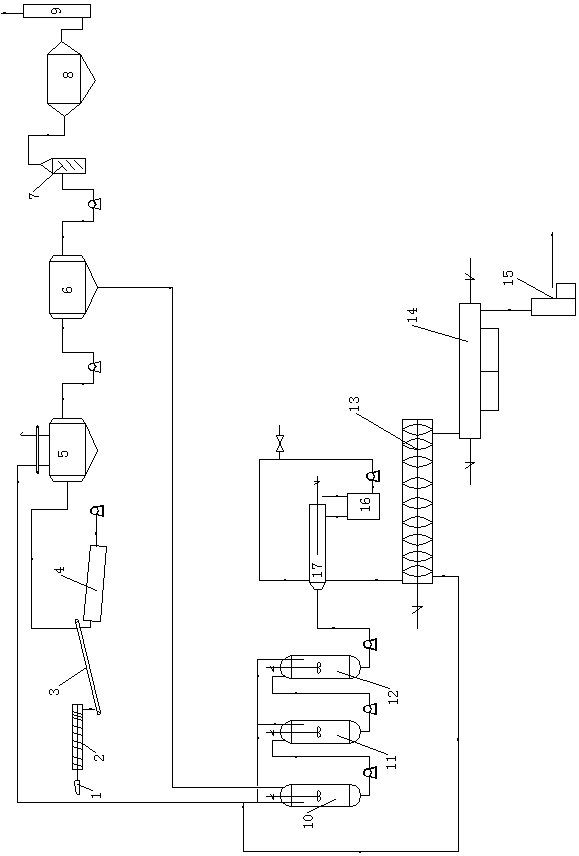

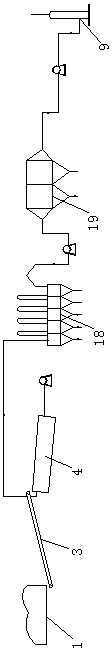

[0033] Mix 83 parts of steelmaking dust ash containing 10% zinc (heat content 1000 kcal) and coke 17 parts (calorific value 8000 kcal). After mixing the ingredients, add binder for granulation. Binders are water, cement and slaked lime, of which 100 parts of zinc-containing dust collection ash and coke mixture, 5 parts of water, 3 parts of slaked lime, 2 parts of cement, the total number of parts is 110 parts; Granulation, the speed of the granulator is controlled at 500 revolutions per minute, and the particle size is 0.5-3mm. After granulation, it is put into the rotary furnace for reduction and oxidation; The zinc content in the leached leaching solution is less than 50mg / L, which is harmless and can be returned to the steelmaking plant as a sintering material for continued use as a refined iron ore; the high-temperature and high-dust kiln gas is fed into the waste heat boiler to produce steam for the wet process section; The dust-laden gas out of the boiler enters the firs...

Embodiment 2

[0036] Mix 95 parts of steelmaking dust ash containing 5% zinc (heat content 1000 kcal) and 5 parts anthracite (calorific value 6000 kcal) and mix the ingredients. After mixing the ingredients, add a binder for granulation. The binder is slaked lime and sodium silicate with 90% water content; the mixture of zinc-containing dust ash and anthracite is 100 parts, 5 parts of sodium silicate with 90% water content, and 3 parts of slaked lime, the total number of parts is 108 parts Enter the granulation of the stirring tooth granulator, the granulator speed is controlled at 300 revolutions per minute, and the particle size is 0.5-3mm. After granulation, enter the rotary furnace for reduction and oxidation, and the weight percentage of zinc in the slag that the rotary furnace tail goes out is less than 0.5%, according to the hazardous waste identification standard, the zinc content in the leaching solution is less than 50mg / L, which is harmless. It will be returned to the steelmaking ...

Embodiment 3

[0039] Mix 88 parts of steelmaking dust collection dust containing 8% zinc (1000 kcal of heat) and 12 parts of coke (8000 kcal of calorific value). The binder is water and cement, in which 100 parts of steelmaking dust collection ash and anthracite mixture, 4 parts of water, 1 part of cement, the total number of parts is 105 parts; it is fed into the agitator granulator for granulation, and the granulator The speed is controlled at 800 revolutions per minute, the particle size is 0.5-3mm, and it is put into the rotary furnace for reduction and oxidation. The weight percentage of zinc in the slag from the tail of the rotary furnace is less than 0.5%. The content is less than 50mg / L, which is harmless. It will be returned to the steelmaking plant as a sintering material for continued use as a concentrate of iron ore; the high-temperature kiln gas enters the waste heat boiler, and the steam produced enters the wet process section; the high-dust tail gas enters the cyclone separato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com