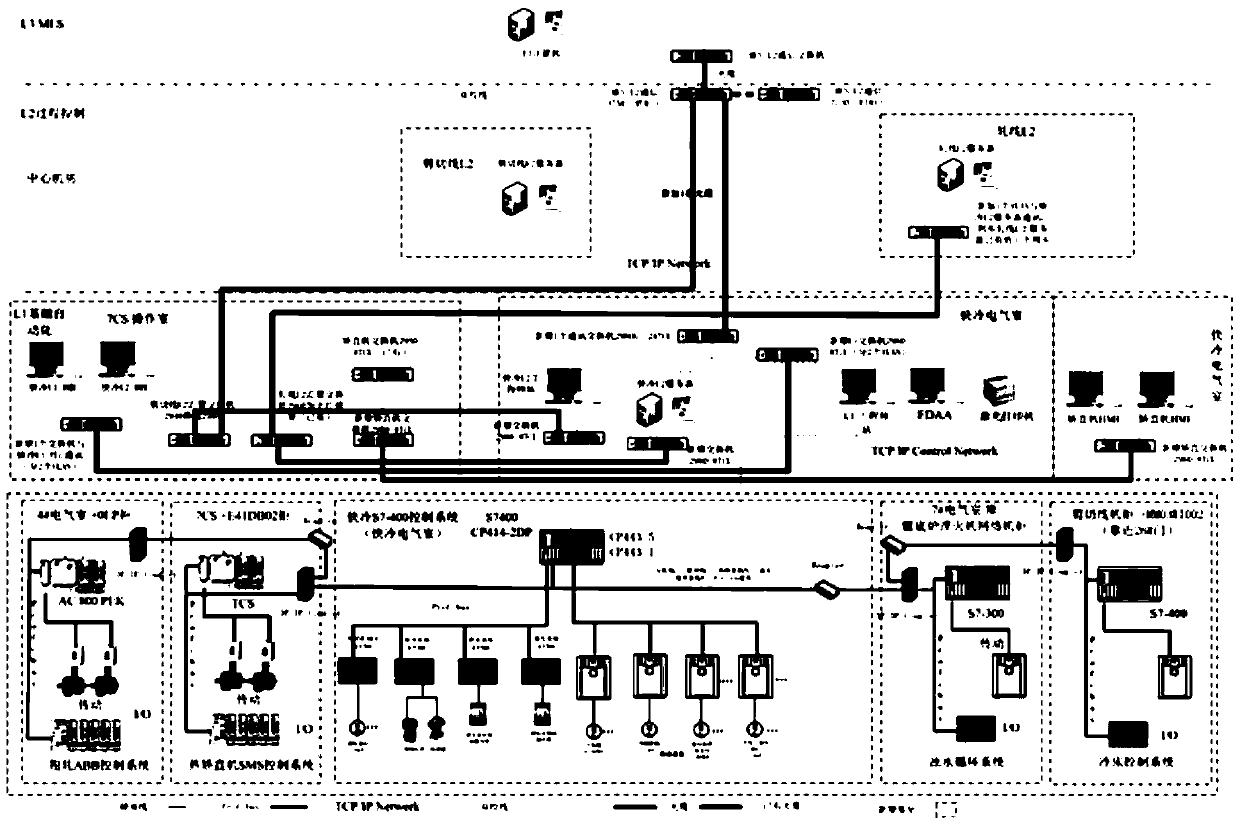

A basic automation system for rapid cooling of steel plates after rolling for on-line solid solution

A basic automation and rapid cooling technology, applied in the field of metallurgy, can solve complex and other problems, and achieve the effect of good plate shape, low investment, compact cooling device and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0234] Example

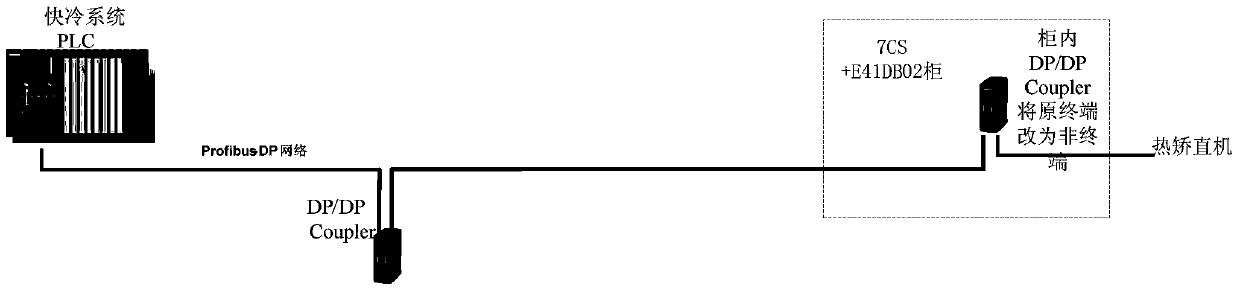

[0235] The main parameters of a specific embodiment of the cooling system after rolling for on-line solid solution of the present invention are as follows (the rapid cooling body operating room of on-line solid solution is 7CS):

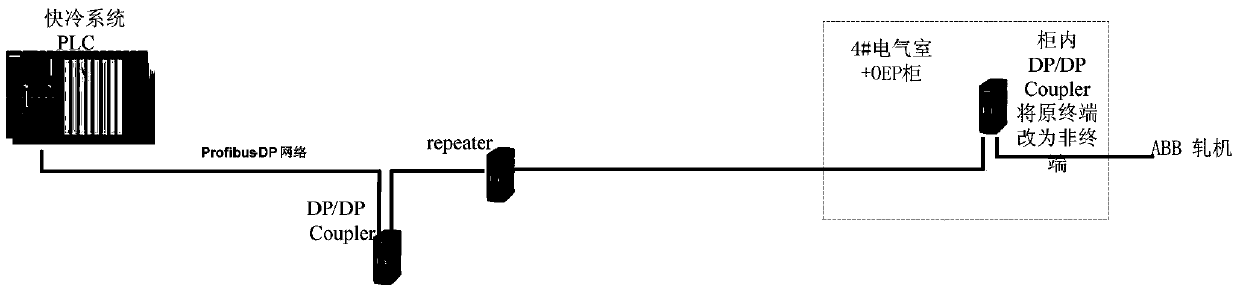

[0236] 8.1 Hardware configuration

[0237] 8.1.1 PLC

[0238] One set of Siemens S7 414-2DP controller is used to control the main body device of quick cooling after rolling, newly added hydraulic station, medium and low pressure feed water pump and water tank, header water flow adjustment, communication with rolling line and hot straightening machine, and process machine Communication with the human operator interface, etc.

[0239] 8.1.2 Operation panel box

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com