Seamless solid core aluminum-calcium core-spun yarn and production system and method thereof

A production system and technology of cored wire, applied in the field of alloy cored wire, can solve the problems such as the inability to store the cored wire for a long time, the reduction of calcium grade and content, the calcium oxidation failure of calcium grade, etc. The effect of enhanced penetration, increased strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

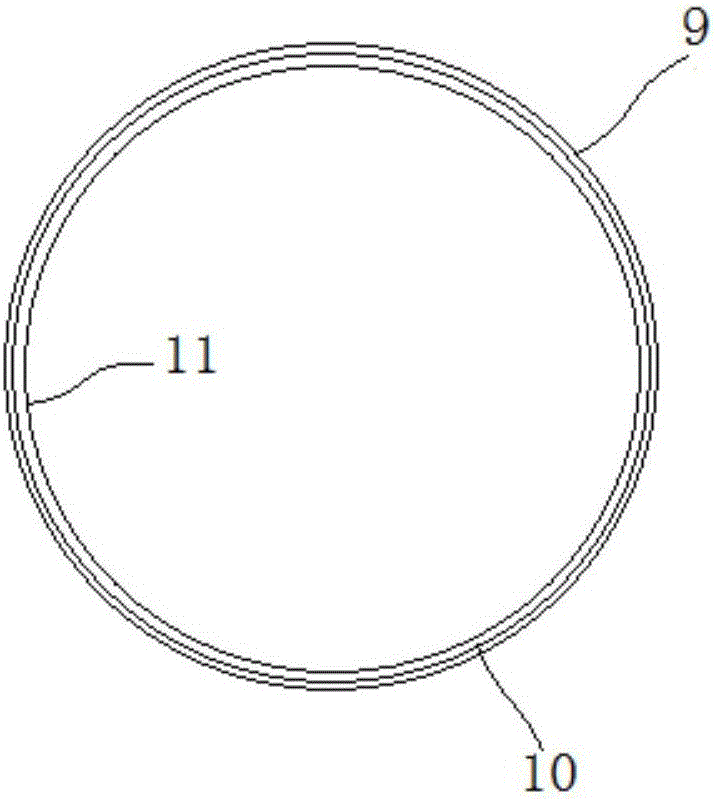

[0043] Such as figure 1 As shown, a seamless solid aluminum-calcium cored wire in this embodiment includes an inner core 11 and an outer skin 10 covering the surface of the inner core 11, the outer skin 10 is a seamless metal aluminum tube, and the The inner core 11 is metal calcium wire or calcium aluminum wire, but it is not limited to calcium metal wire, and other metal wires that need to be coated can also be used, such as titanium wire. The inner core 11 of the present embodiment is metal calcium Wire, and the metal aluminum tube is a seamless metal aluminum tube formed by extruding and perforating an aluminum rod. The outer surface of the above-mentioned metal aluminum tube is provided with an inert passivation layer 9, the inert passivation layer 9 of the present embodiment is an organically modified silicone resin layer, and other inert passivation layers can also be selected, and the outer diameter of the metal aluminum tube is Ф9.0-13mm, inner diameter Ф6-8mm, tole...

Embodiment 2

[0051] Such as figure 1 As shown, a seamless solid aluminum-calcium cored wire in this embodiment includes an inner core 11 and an outer skin 10 covering the surface of the inner core 11, the outer skin 10 is a seamless metal aluminum tube, and the The inner core 11 is a calcium aluminum wire, and the metal aluminum tube is a seamless metal aluminum tube formed by extruding and perforating an aluminum rod. The outer surface of the metal aluminum tube is provided with an inert passivation layer 9, and the outer diameter of the metal aluminum tube is Ф9.0-13mm, the inner diameter is Ф6-8mm, the tolerance is -0.5mm, and the diameter of the calcium aluminum wire is Ф6- 8mm, the interference fit between the aluminum tube and the calcium aluminum wire. In the cored wire of this embodiment, the weight of the calcium-aluminum wire accounts for 30-55%, the weight of the Al tube accounts for 45-70%, and the total weight of the core wire is ≧285g / m.

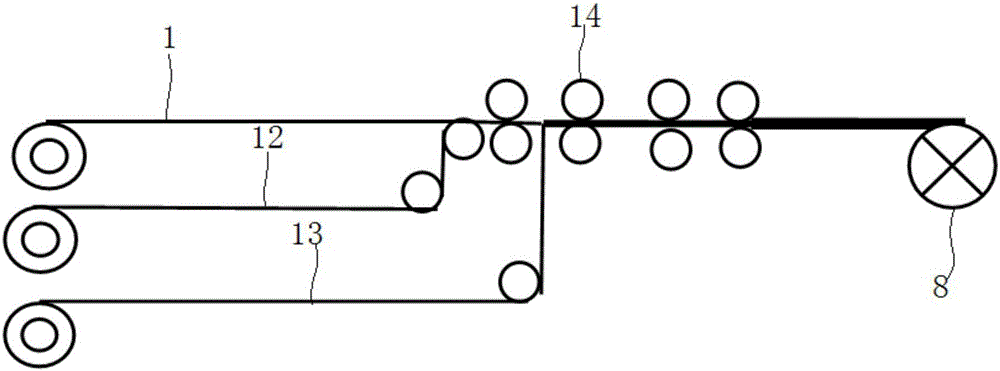

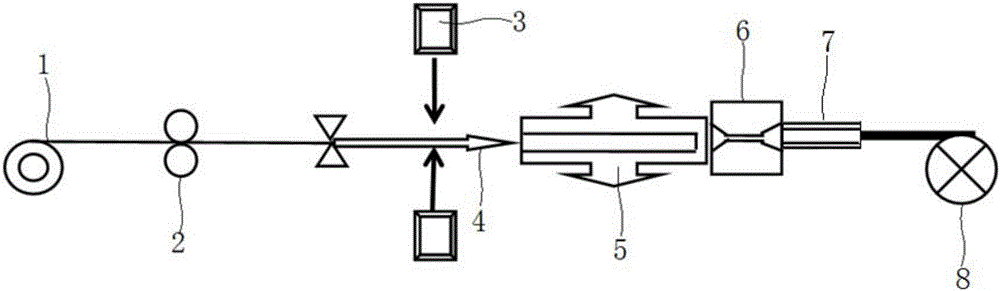

[0052]The production system of th...

Embodiment 3

[0059] Such as figure 1 As shown, a seamless solid aluminum-calcium cored wire in this embodiment includes an inner core 11 and an outer sheath 10 covering the surface of the inner core 11, the outer sheath 10 is a metal aluminum tube, and the inner core 11 is a titanium wire, and the metal aluminum tube is a seamless metal aluminum tube formed by extruding and perforating an aluminum rod. The outer surface of the metal aluminum tube is provided with an inert passivation layer 9, and the outer diameter of the metal aluminum tube is Ф9.0-13mm, the inner diameter is Ф6-8mm, the tolerance is -0.5mm, and the diameter of the titanium wire is Ф6-8mm , There is an interference fit between the aluminum tube and the titanium wire. In the cored wire of this embodiment, the weight of titanium wire accounts for 30-55%, the weight of Al tube accounts for 45-70%, and the total weight of the core wire is ≧285g / m.

[0060] The production system of the above-mentioned seamless solid aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com