A production method of passivated pure calcium cored wire

A technology of pure calcium cored wire and production method, which is applied in the field of refining outside the steelmaking furnace, can solve the problems of reducing production continuity, reducing work efficiency, reducing the passivation effect of calcium wire, etc., and achieves slowing down boiling and splashing, Reduce safety accidents and protect against oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

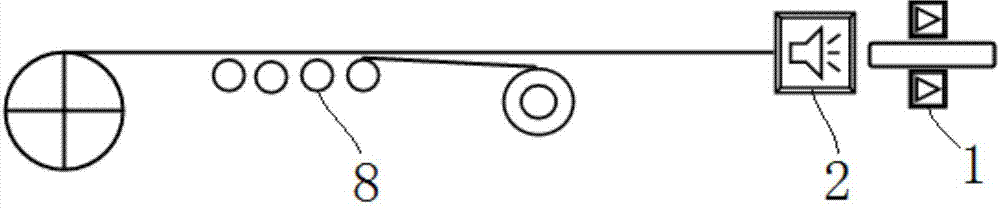

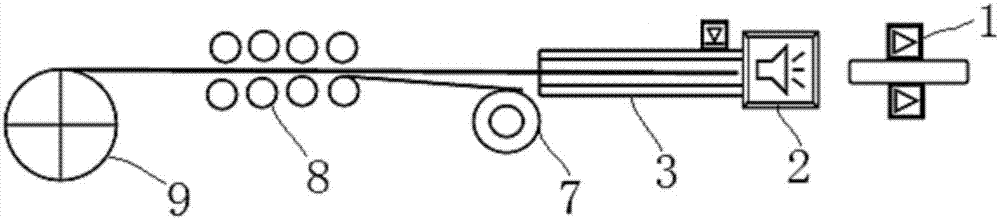

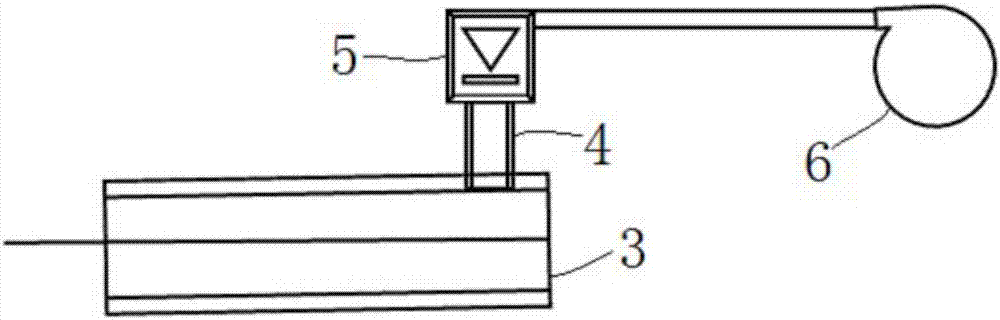

[0039] Such as figure 2 As shown, a production system of passivated pure calcium cored wire in this embodiment includes a heater 1, an extruder 2, a cored wire unit 8, a passivation processor 3 and an automatic filling mechanism. Wherein, the heater 1 is located at the feed end of the extruder 2, the inlet end of the passivation processor 3 is located at the discharge end of the extruder 2, and the outlet end of the passivation processor 3 is provided with a cored wire unit 8. The pure calcium cored wire to be processed passes through the heater 1, extruder 2, passivation processor 3 and cored wire unit 8 in sequence, wherein the above extruder 2 is used to extrude calcium rods into calcium The passivation processor 3 is used to passivate the calcium filament. A liquid inlet is provided on the upper part of the passivation processor 3, and the inlet end and the outlet end of the passivation processor 3 are sealed soft joints, and the passivation processor 3 is used to hold p...

Embodiment 2

[0059] A kind of production method of passivated pure calcium cored wire of the present embodiment, its steps are:

[0060] Step 1, preparation of passivation solution

[0061]Weigh the methyl silicone oil and talcum powder according to the weight percentage of 90% and 10% respectively, place the weighed methyl silicone oil and talcum powder in a high-speed stirring tank and stir for 30 minutes to obtain the required passivation solution, And it is packed into passivation processor 3 and passivation liquid storage tank, the alkalinity PH of gained passivation liquid is 6.5;

[0062] Step 2. Heating and extrusion of calcium rods into filaments

[0063] Start the production system of passivated pure calcium cored wire, heat the pure calcium rod to be processed with heater 1, and place it in extruder 2 for extrusion after the calcium rod is heated to the plastic extrusion molding temperature , so that it is extruded into a metal calcium wire of Ф7mm, and the mass fraction of Ca...

Embodiment 3

[0070] A kind of production method of passivated pure calcium cored wire of the present embodiment, its steps are:

[0071] Step 1, preparation of passivation solution

[0072] Weigh the methyl silicone oil and talcum powder according to the weight percentage of 95% and 5% respectively, place the weighed methyl silicone oil and talcum powder in a high-speed stirring tank and stir for 25 minutes to obtain the required passivation solution, And it is packed into passivation processor 3 and passivation liquid storage tank, the alkalinity PH of gained passivation liquid is 6;

[0073] Step 2. Heating and extrusion of calcium rods into filaments

[0074] Start the production system of passivated pure calcium cored wire, heat the pure calcium rod to be processed with heater 1, and place it in extruder 2 for extrusion after the calcium rod is heated to the plastic extrusion molding temperature , so that it is extruded into a metal calcium wire of Ф8mm, and the mass fraction of Ca i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com