A kind of antibacterial enhanced hdpe pipeline functional masterbatch and preparation method thereof

A functional masterbatch and pipeline technology, applied in the field of antibacterial enhanced HDPE pipeline functional masterbatch, can solve the problems of low pressure resistance, low ring stiffness, HDPE pipeline does not have antibacterial and mildew resistance, achieve good ring stiffness, solve particle agglomeration, The effect of solving the difficulty of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] An antibacterial and enhanced HDPE pipeline function masterbatch, which is composed of the following components by mass percentage: HDPE resin (model: GM-5010H) 89.94%, four-needle zinc oxide whisker 3%, inorganic nano antibacterial agent 6% (of which nano Copper oxide 3%, nano zirconia 3%), water-based dispersant (dispersant WF211) 0.03%, water-based coupling agent (silane coupling agent KH-560) 0.03%.

[0034] Among them, the melt index of HDPE (model: GM-5010H) is 0.5g / 10min. The melt index test standard is ASTM D 1238.

Embodiment 2

[0036] Except HDPE resin (model: GM-5010H) 86.94%, four-needle zinc oxide whisker 4%, inorganic nano-antibacterial agent 8% (including nano-copper oxide 4%, nano-zirconia 4%), others are the same as in Example 1 same.

Embodiment 1 and 2

[0037] The preparation method of embodiment 1 and 2 is:

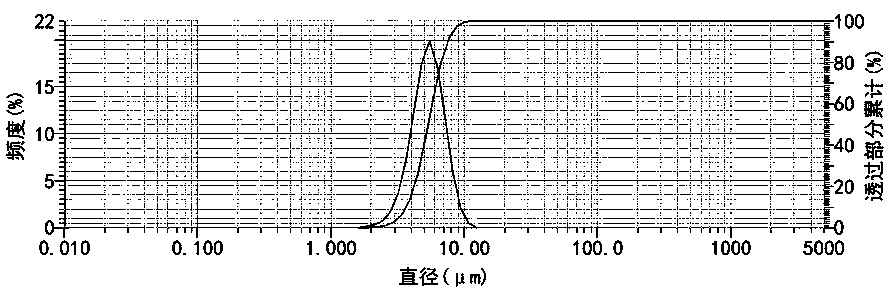

[0038] (1) Add deionized water, micron zirconia and water-based dispersant (dispersant WF211) into a vertical grinder in proportion to grind for 90 minutes, and grind it into a nano-zirconia material with an average particle size of less than 200nm;

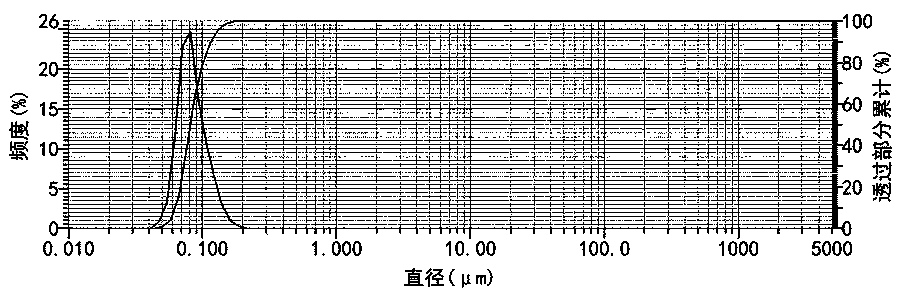

[0039] (2) Then add micron copper oxide into the vertical grinder and continue to grind the nano-zirconia material obtained in step (1) for 90 minutes, so that the above two raw materials are ground into nano-materials with an average particle size of less than 100nm;

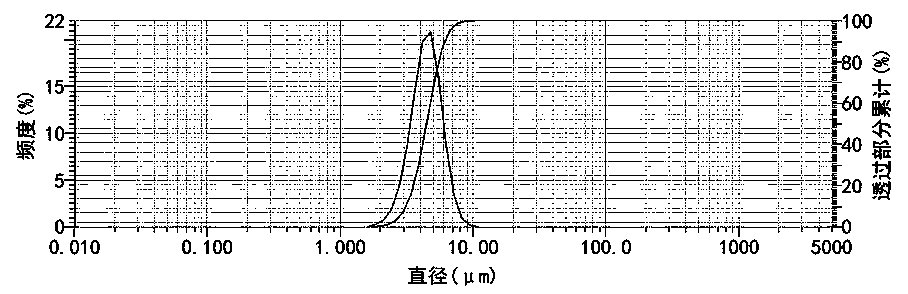

[0040] (3) Then add the water-based coupling agent (silane coupling agent KH-560) into the vertical grinder and continue grinding for 20 minutes to form a water-based nanocomposite antibacterial liquid;

[0041] (4) Ultrasonicate the water-based nano-composite antibacterial liquid obtained in step (3) for 5 minutes and spray it on the HDPE resin (model: GM-5010H) preheated to 90°C on the high-speed mixer wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com