Zwitterionic polymer microspheres and preparing method thereof

A zwitterionic, hydrophobic polymer technology, applied in the field of bioseparation and biomedical engineering, to achieve the effect of reducing the background value, superior reagent performance, and broad application value of immunoassay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

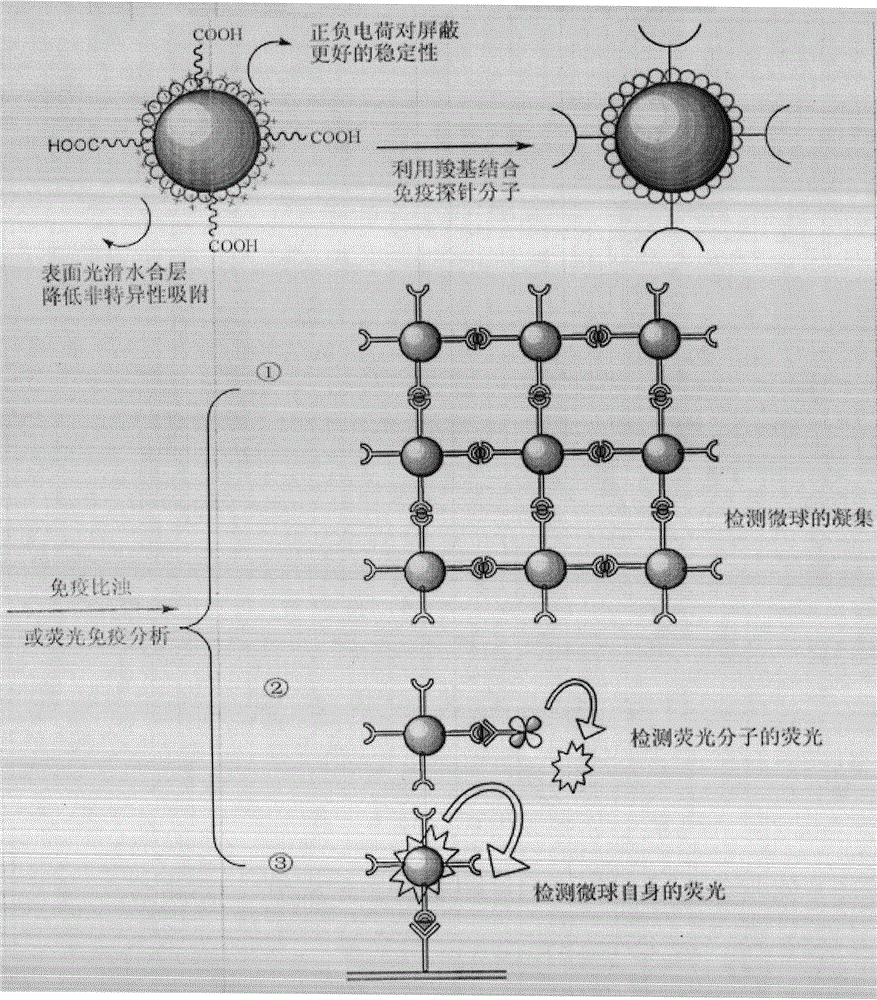

Method used

Image

Examples

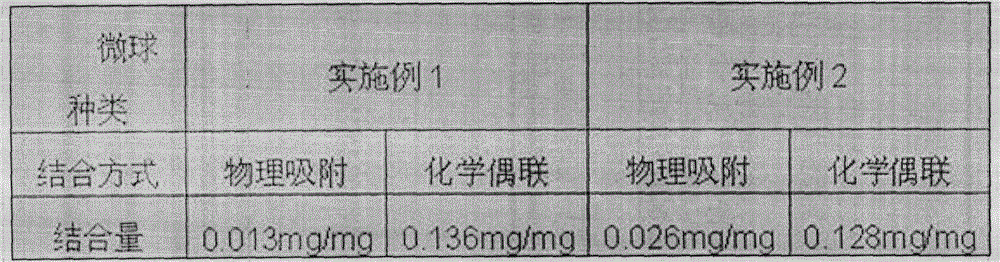

Embodiment 1

[0050] Example 1 Preparation of phosphoric acid type zwitterionic polystyrene microspheres

[0051] Add 45 mg of sodium dodecylsulfonate to a four-necked flask equipped with a condenser tube (the top of the condenser tube needs to be connected to a drying tube), nitrogen passage, magnetic stirring, and water bath heating, and add 100 mL of purified water and stir to dissolve. Then pass nitrogen to remove oxygen, and the flow rate of the air flow is moderate. It is advisable to introduce nitrogen into the medium so that there are continuous small bubbles coming out, and the air flow is uninterrupted. During nitrogen flow, use a pipette to measure 4mL of purified styrene, and slowly add it dropwise through the feeding port of the four-neck flask, weigh 36mg of potassium persulfate, dissolve it in 1mL of purified water, and add it to the reaction system. The temperature was set to 85° C., and the polymerization was initiated by heating. Weigh 10 mg of 2-methacryloyloxyethyl phos...

Embodiment 2

[0056] Example 2 Preparation of Carboxylic Acid Type Zwitterionic Polystyrene Microspheres

[0057] Preparation method is with reference to embodiment 1, and specific implementation method is as follows:

[0058] Add 45 mg of sodium dodecylsulfonate to a four-necked flask, add 100 mL of purified water and stir to dissolve. Then, oxygen was blown with nitrogen gas. During the nitrogen gas flow, 4 mL of styrene was measured with a pipette, and slowly added dropwise through the feeding port of the four-neck flask. Weigh 36mg of potassium persulfate, dissolve it with 1mL of purified water, add it to the reaction system, set the temperature of the water bath to 85°C, and heat to initiate polymerization. Weigh 10 mg of N,N-dimethyl-N-methacryloyloxyethyl-N-acetic acid inner salt, dissolve it with 1 mL of long-chain carboxyl monomer and stir until it becomes milky white, and keep nitrogen gas flowing during this process. The milky white liquid was added to the styrene reaction syst...

Embodiment 3

[0060] Example 3 Preparation of phosphoric acid type zwitterionic polystyrene magnetic microspheres

[0061]Add 130ml of water and 20ml of ethanol into a four-necked flask equipped with a condenser tube, nitrogen passage, ultrasonic vibration rod and mechanical stirring, and mix well, then add 90mg of sodium dodecylsulfonate and 270mg of cetyl alcohol, and heat to 50°C. Dissolve it and pass nitrogen gas to remove oxygen. Set the stirring blade speed to 500rpm. During nitrogen flow, pipette 10ml styrene with a pipette and add it to 0.4g oleic acid-modified ferric oxide. Ultrasonic dispersion is uniform and then slowly added dropwise into the four-necked flask reaction system. Add 36 mg of potassium persulfate aqueous solution, and turn on the ultrasound (power 650W, frequency 30%, working for 2 seconds, intermittent for 1 second), to disperse the oil-soluble monomer and magnetic particles evenly to form a uniform gray reaction system, and finally add positive ten Hexane 2ml to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com