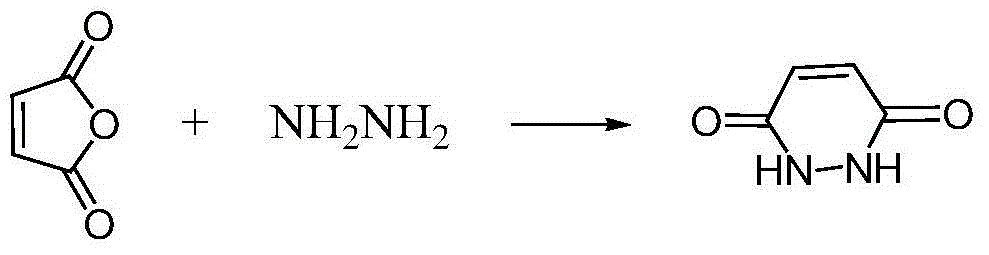

Maleic hydrazide preparation method

A technology of maleic hydrazide and hydrazine hydrate, applied in the direction of organic chemistry, can solve the problems of high residual hydrazine of maleic hydrazide, incomplete reaction, low conversion rate of raw materials and low product yield, and achieve low cost and high quality , Reasonable effect of synthetic process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In a 1000ml four-neck round bottom flask equipped with mechanical stirring, thermometer and condenser tube, add 250g of water, 44g of concentrated sulfuric acid and 44ml of hydrazine hydrate, and react with 0.8g of lanthanum trifluoromethanesulfonate at 30-40°C for 30 minutes Then add 100g of maleic anhydride, heat up to 80-90°C and react for 1 hour, cool down to 40-50°C, add 80ml of 30% sodium hydroxide solution, neutralize to pH 6.5, filter, wash with water, and dry to obtain maleic hydrazide 98.3g (mp: 306-307°C, yield 96.7%).

Embodiment 2

[0022] In a 1000ml four-neck round bottom flask equipped with mechanical stirring, thermometer and condenser, add 250g of water, 55g of concentrated sulfuric acid and 44ml of hydrazine hydrate, 4g of lanthanum trifluoromethanesulfonate and react at 30-40°C for 30 minutes Add 125g of maleic anhydride, heat up to 90-100°C for 5 hours, cool down to 40-50°C, add 100ml of 30% sodium hydroxide solution, neutralize to pH 6.5, filter, wash with water, and dry to obtain maleic hydrazide 98.5 g (mp: 306-307°C, yield 96.9%).

Embodiment 3

[0024] In a 1000ml four-neck round bottom flask equipped with mechanical stirring, thermometer and condenser tube, add 250g of water, 66g of concentrated sulfuric acid and 44ml of hydrazine hydrate, 8g of lanthanum trifluoromethanesulfonate and react at 30-40°C for 30 minutes Add 150g of maleic anhydride, raise the temperature to 110-120°C for 10 hours, cool down to 40-50°C, add 120ml of 30% sodium hydroxide solution, neutralize to pH 6.5, filter, wash with water, and dry to obtain maleic hydrazide 98.8 g (mp: 306-307°C, yield 97.2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com