Preparation method of ethyl 6,8-dichlorocaprylate

A technology of ethyl dichlorooctanoate and ethyl chlorooctanoate, which is applied in the field of preparation of organic compound intermediates, can solve the problems of excessive nitrogen-containing wastewater, low product yield, and failure to recycle, and achieve small waste and high reaction yield , The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

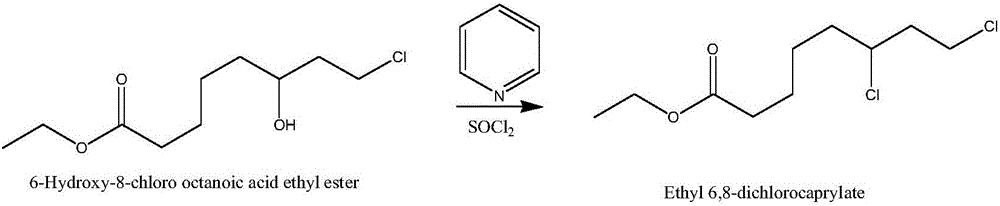

Image

Examples

example 1

[0026] In the organic solvent dichloroethane, 6-hydroxy-8-chlorooctanoic acid ethyl ester and chlorination reagent thionyl chloride are used as acid-binding agents in N,N-dimethylbenzylamine, and 6-hydroxy-8-chlorooctanoic acid ethyl The molar ratio of ester, chlorinating reagent, and N,N-dimethylbenzylamine is 1:1.02:0.2, the weight ratio of organic solvent to ethyl 6-hydroxy-8-chlorooctanoate is 3:1, and the temperature is - Add N,N-dimethylbenzylamine dropwise at 5°C. The holding temperature is 85°C and the holding time is 30 minutes. In the obtained reaction solution, add water to separate layers. The weight ratio of water to ethyl 6-hydroxy-8-chlorooctanoate is 1:0.5, the upper layer is the organic phase.

[0027] Vacuum degree of 5mmHg and temperature of 172-176°C are collected by rectification under reduced pressure, which is 6,8-dichlorooctanoic acid ethyl ester. The molar yield of the product is 95.24%, and the purity is 96.53%. , layered, and the upper layer was deh...

example 2

[0030] In organic solvent dichloromethane, 6-hydroxy-8-chlorooctanoic acid ethyl ester and chlorination reagent solid phosgene are used as acid-binding agent in N,N-dimethylbenzylamine, 6-hydroxy-8-chlorooctanoic acid ethyl ester, The molar ratio of chlorination reagent and N,N-dimethylbenzylamine is 1:1.40:0.3, and the weight ratio of organic solvent to 6-hydroxy-8-chlorooctanoic acid ethyl ester is 2.4:1, when the temperature is 0°C Add N,N-dimethylbenzylamine dropwise, keep the temperature at 70°C, and keep it for 60 minutes to obtain the reaction solution, add water to separate layers, and the weight ratio of water to ethyl 6-hydroxy-8-chlorooctanoate is 1:1 , the upper layer is the organic phase.

[0031] Vacuum degree of rectification is 5mmHg, the fraction with temperature of 172-176°C is collected by rectification under reduced pressure, which is 6,8-dichlorooctanoic acid ethyl ester, the product molar yield is 95.17%, and the purity is 96.35%. 10. Separate the layers...

example 3

[0033] In organic solvent toluene, 6-hydroxy-8-chlorooctanoic acid ethyl ester and chlorination reagent solid phosgene are used as acid-binding agent in N, N-dimethylbenzylamine, 6-hydroxy-8-chlorooctanoic acid ethyl ester, chlorination The molar ratio of reagent and N,N-dimethylbenzylamine is 1:1.05:0.1, and the weight ratio of organic solvent to 6-hydroxy-8-chlorooctanoic acid ethyl ester is 1:1. Add dropwise at a temperature of 5°C N,N-Dimethylbenzylamine, the holding temperature is 60°C, and the holding time is 120min. In the obtained reaction solution, add water to separate layers. The weight ratio of water to ethyl 6-hydroxy-8-chlorooctanoate is 1:1.5, and the upper layer for the organic phase.

[0034] Vacuum degree of 5mmHg and temperature of 172-176°C are collected by rectification under reduced pressure, which is 6,8-dichlorooctanoic acid ethyl ester. The molar yield of the product is 95.32%, and the purity is 96.63%. Add sodium carbonate to the lower layer to adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com