High pollution resistance membrane bioreactor and sewage treatment method

A technology of membrane bioreactor and biochemical reaction, applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve high treatment cost, frequent membrane cleaning, affecting membrane flux, etc. problems, to achieve the effect of low treatment cost, long membrane cleaning cycle, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

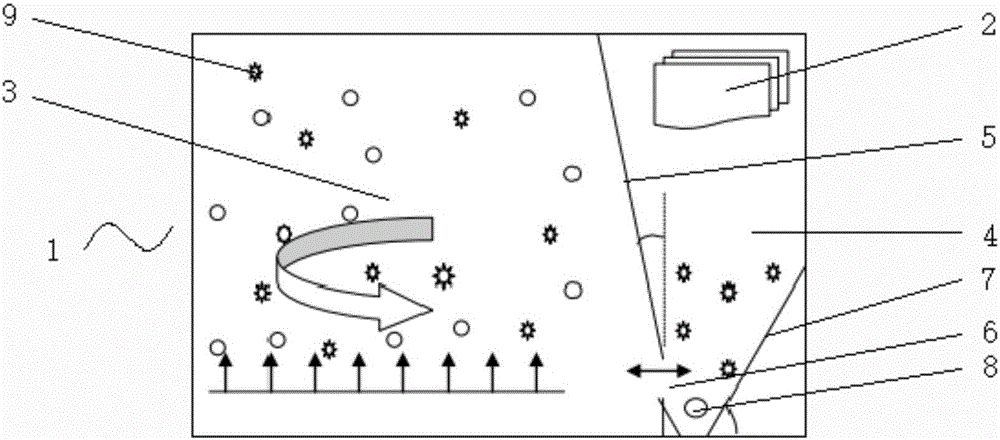

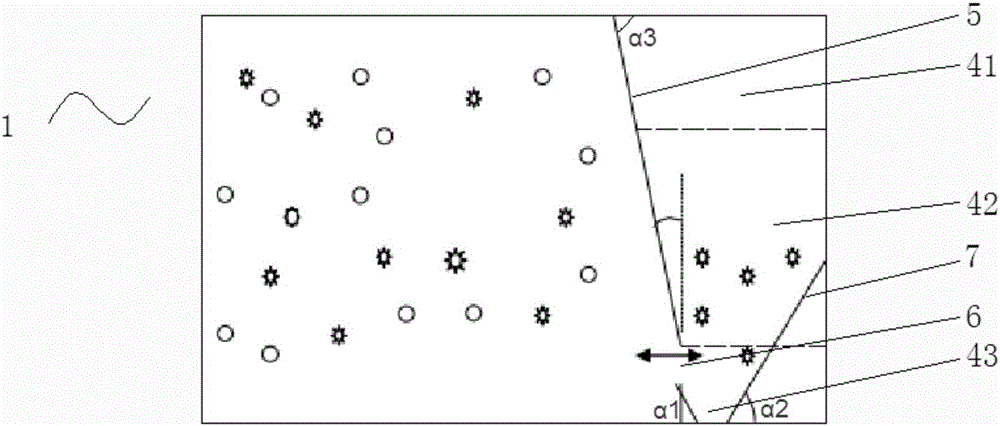

[0032] Such as figure 1 Or as shown in 2, in the high pollution-resistant membrane bioreactor 1 of the present invention, a membrane module 2 is provided in the membrane bioreactor 1, and a partition board 5 is provided in the membrane bioreactor 1 near the water outlet end. The angle α3 with the upper surface of the membrane bioreactor 1 is 20-90°, the partition 5 is provided with mud and water inlets and outlets 6 near the middle and lower parts of the membrane bioreactor 1, and the partition 5 divides the membrane The bioreactor is divided into a biochemical reaction zone 3 and a mud-water separation zone 4. The biochemical reaction zone 3 performs sewage biochemical treatment, the mud-water separation zone 4 performs mud-water separation, sludge return and membrane effluent, and the mud-water separation zone 4 is divided into The membrane module 2 is immersed in the clean water zone 41, the mud-water automatic separation and sludge unpowered automatic return zone 42 and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com