Pressure swing adsorption nitrogen making device capable of replacing membrane separation nitrogen making

A technology of pressure swing adsorption and membrane separation, which is applied in nitrogen purification/separation, nitrogen compounds, inorganic chemistry, etc. It can solve the problems of large footprint, achieve small dead space, reduce tower weight, and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

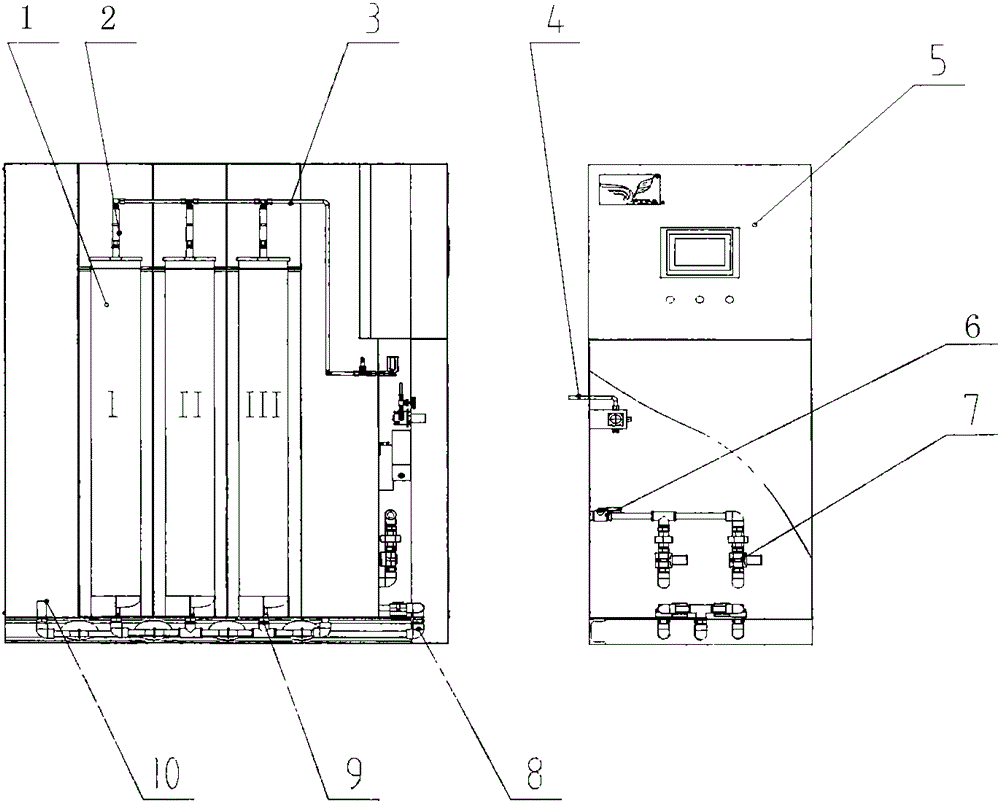

[0009] Three sets of adsorption tower groups (1 in the figure) are arranged vertically, and each adsorption tower group is equipped with an independent manual air outlet valve (2 in the figure) and an independent manual air inlet valve (9 in the figure), turn on the power supply of the device (in the figure 5) and the total air intake manual valve (6 in the figure), the compressed air enters the left tower of the adsorption tower group for adsorption from the intake valve of the left and right towers (7 in the figure), and the qualified nitrogen gas is discharged from the outlet pipeline (3 in the figure), and finally passes through The product gas supply pipeline (4 in the figure) is supplied to downstream users, and at the same time, the right tower of the adsorption tower group is desorbed and regenerated. The desorbed gas is discharged through the exhaust pipeline (8 in the figure) and the muffler (10 in the figure). After one cycle, The left and right towers are switched, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com