Material clamping and conveying device of prefabricated bag packaging machine

A clamping conveying and packaging machine technology, applied in packaging and other directions, can solve the problems of low material conveying efficiency, shortened clamping stroke, irregularity, etc., and achieve high packaging efficiency, shortened clamping stroke, and low replacement cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

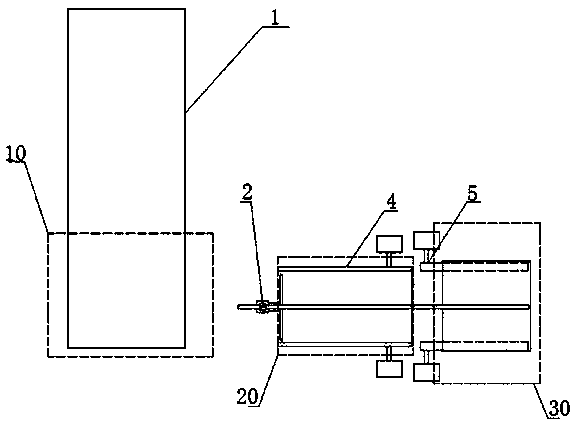

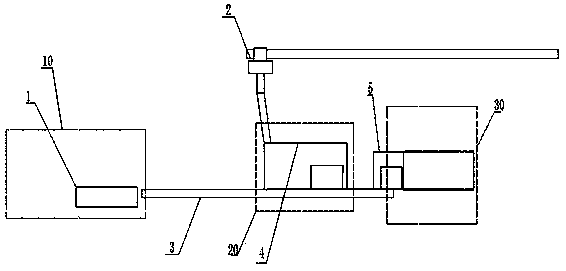

[0076] The material clamping and conveying device of the prefabricated bag packaging machine includes a translation mechanism 3 and a clamping mechanism 4 connected to the translation mechanism 3 , and the clamping mechanism 4 reciprocates along the material running direction under the action of the translation mechanism 3 .

[0077] The clamping mechanism reciprocates along the running direction of the material under the action of the translation mechanism, and the clamping mechanism will not shake during the conveying process of the clamped material, which greatly improves the clamping stability, and the clamping mechanism has a greater impact on the material. The clamping action is continuous and reciprocating, and the material conveying and clamping are coordinated separately, which shortens the entire clamping stroke and improves the packaging efficiency of the subsequent prefabricated bags; since the material is clamped and transported, it will not cause material dumping ...

Embodiment 2

[0079] The material clamping and conveying device of the prefabricated bag packaging machine includes a translation mechanism 3 and a clamping mechanism 4 connected to the translation mechanism 3, and the clamping mechanism 4 reciprocates along the material running direction under the action of the translation mechanism 3;

[0080] A clamping cylinder 42 is also included, and the clamping mechanism 4 is driven by the clamping cylinder 42 .

[0081] The clamping mechanism is driven by the clamping cylinder, and the clamping mechanism is driven by the clamping cylinder to clamp the material, which can easily realize the clamping action, and the replacement cost of the clamping cylinder is low.

Embodiment 3

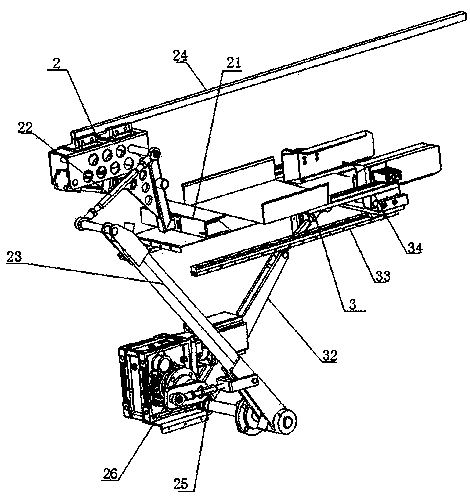

[0083] The material clamping and conveying device of the prefabricated bag packaging machine includes a translation mechanism 3 and a clamping mechanism 4 connected to the translation mechanism 3, and the clamping mechanism 4 reciprocates along the material running direction under the action of the translation mechanism 3;

[0084] It also includes a clamping cylinder 42, and the clamping mechanism 4 is driven by the clamping cylinder 42;

[0085] The clamping mechanism 4 includes two clamping plates 41, and the two clamping plates 41 are arranged in parallel;

[0086] There are two clamping cylinders 42 , one clamping cylinder 42 is respectively connected to the two clamping plates 41 , and the two clamping cylinders 42 drive the two clamping plates 41 to approach or separate from each other in the horizontal direction.

[0087] The clamping mechanism includes two clamping plates, and the two clamping plates are arranged in parallel. With this arrangement, the material is mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com