Heavy-duty car motor drive air braking system and braking method

A motor-driven, pneumatic braking technology, applied in the direction of brake transmission, brakes, vehicle components, etc., can solve the problems of high cost and complex hardware, and achieve the effect of long service life, safe braking and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

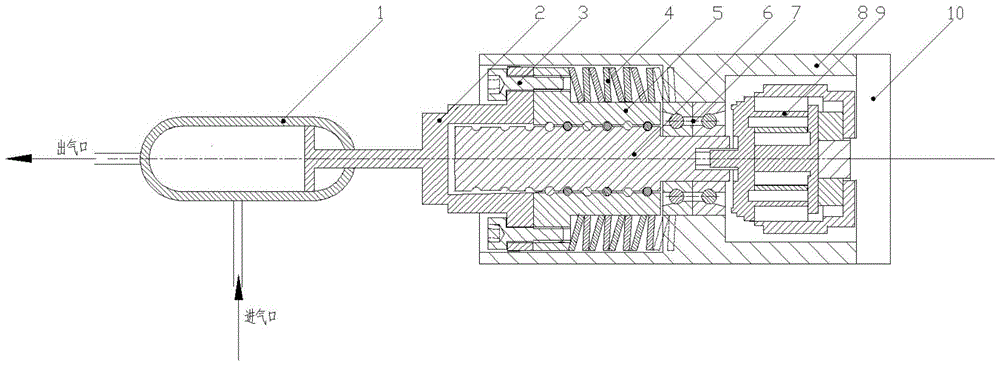

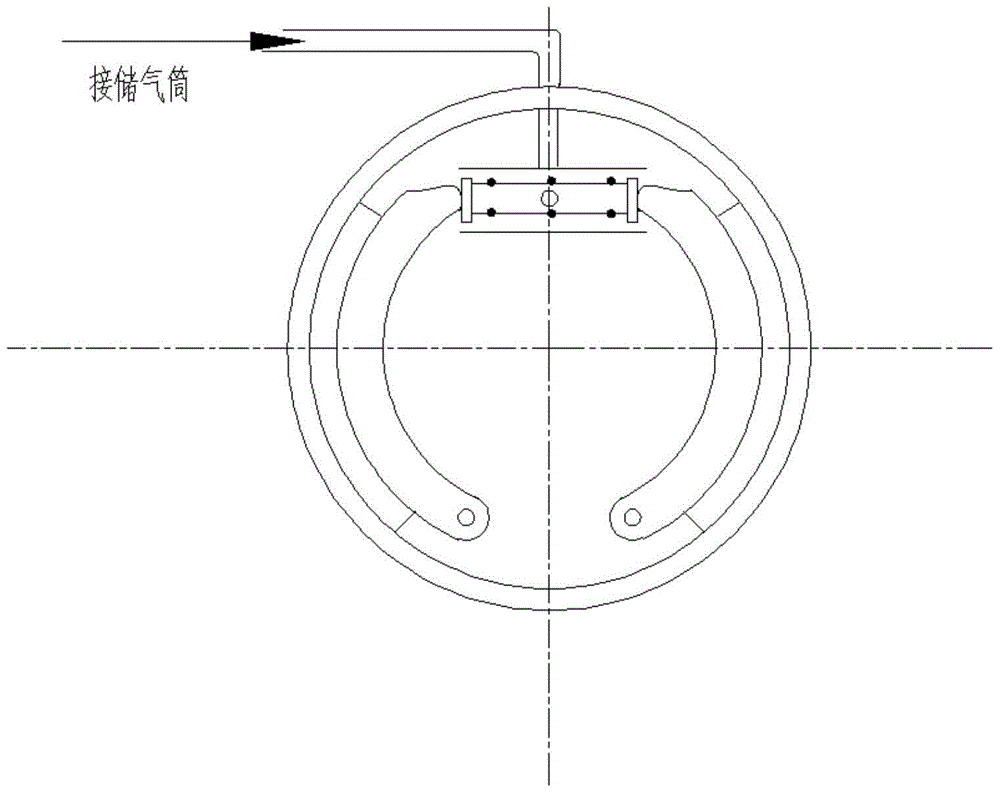

[0034] The realization principle of the present invention: comprises air reservoir, the drive mechanism that pushes the piston rod in the gas reservoir, ECU control unit and the speed sensor that monitors the running state of automobile and train, brake pedal opening sensor. The air storage tank is provided with a piston, an air outlet, an air inlet and a pressure sensor. The piston is fed by the push rod force of the driving mechanism, the air outlet is connected to the brake wheel cylinder, and the air inlet is connected to the air pressure pipeline. When the brake command is received, the air inlet is closed, the air outlet is opened, the piston pushes the air pressure forward to the brake wheel cylinder, the brake wheel cylinder brake pressure is monitored by the pressure sensor and fed back to the ECU control unit, and the ECU co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com