Method for conducting cutting blanking on cylindrical steel

A steel and cylindrical technology, applied in the field of auxiliary devices in the cutting process of steel cutting tools, can solve the problems of incision inclination and disadvantage, and achieve the effect of reducing the turning force and increasing the force arm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

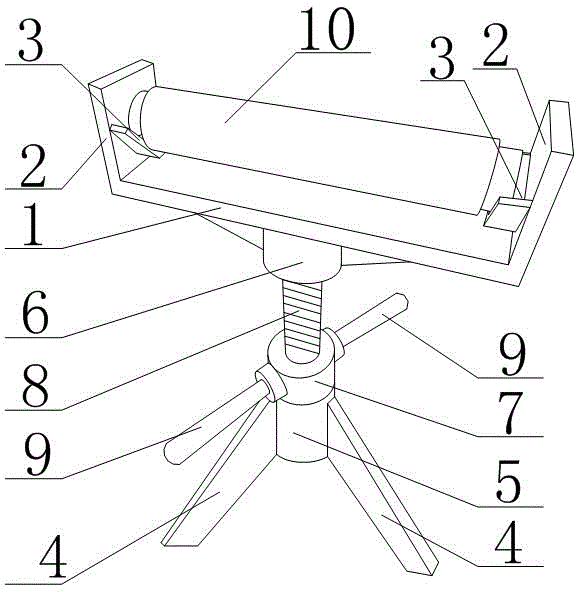

[0017] Such as figure 1 As shown, a method for cutting and blanking cylindrical steel materials in the present invention includes a tripod 4 placed on the ground, a sleeve 5 is fixedly arranged on the axis of the tripod 4, and a sleeve 5 is arranged on the sleeve 5. The rotating cylinder 7 that can rotate around the axis of the sleeve 5 is provided with an internal thread inside the rotating cylinder 7. The rotating cylinder 7 is fixed relative to the sleeve 5 on its axis, and two rotating handles are arranged on the side wall of the rotating cylinder 7. 9. The two rotating handles 9 are located on the same diameter of the rotating cylinder 7, and the lifting screw 8 is set in the rotating cylinder 7 and the sleeve 5, and the top of the lifting screw 8 is set in the holding cylinder 6, and the inside of the holding cylinder 6 is smooth , a flat plate 1 is installed on the top of the holding tube 6, the center of gravity of the flat plate 1 is located on the axis of the holding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com