Annular laser welding head and annular laser welding method

A laser welding head, laser welding technology, used in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problem of easy cracking in the central part, reduce ablation, improve welding quality, avoid energy density Gaussian distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

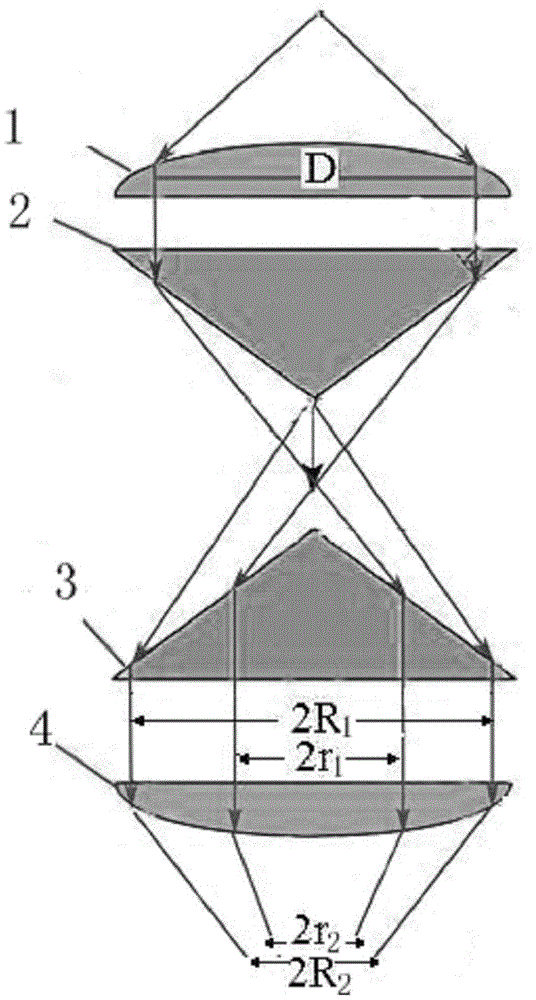

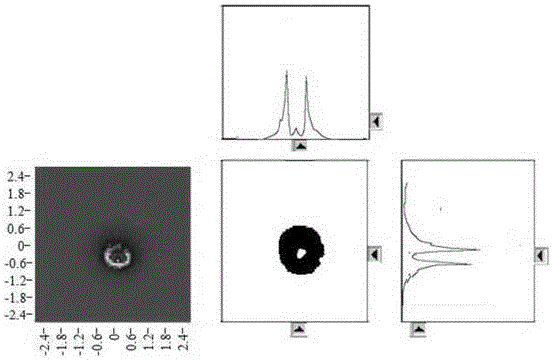

[0024] In this embodiment, the focal length of the collimating lens is selected as f=60mm, and the distance between the two circular lenses is adjusted to 61.5mm. By adjusting the coaxial performance of the three cones and measuring the energy density distribution of the annular beam with a beam measuring instrument, the obtained OD 2R 1 =55mm, inner diameter 2r 1 =44.2mm, the ring width W=5.4mm, and the larger ring laser beam with uniform energy density distribution. Since the beam passing through the second conical lens is a parallel beam and is vertically irradiated on the focusing mirror, the distance between the second conical lens and the focusing mirror has almost no influence on the focusing characteristics of the beam, keeping the second conical lens The distance between the lens and the focusing lens is 15mm, and a focusing lens with a focal length f=60mm is added under the second conical lens. Gained outer diameter 2R at focus 2 =2.0mm, inner diameter 2r 2 =1.7m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com