A Universal Welding Fixture Suitable for Manufacture of Fully Loaded Chassis

A welding fixture and full load-bearing technology, which is applied in the direction of manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems of lower frame assembly quality, occupying a large area of the site, and increasing investment costs, etc. Easy operation and convenient welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

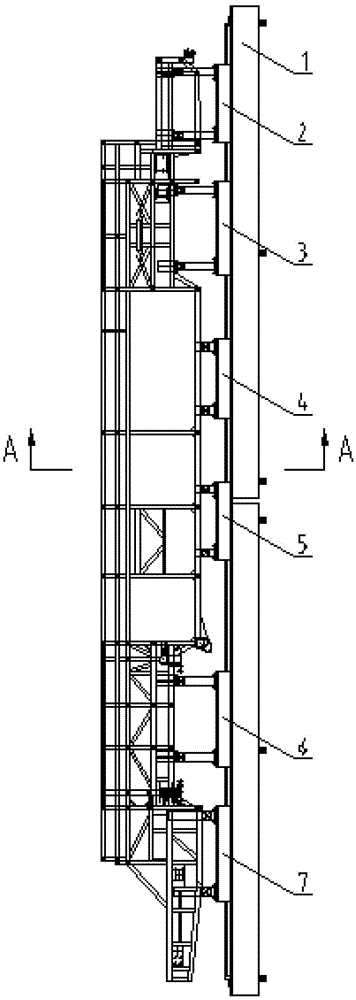

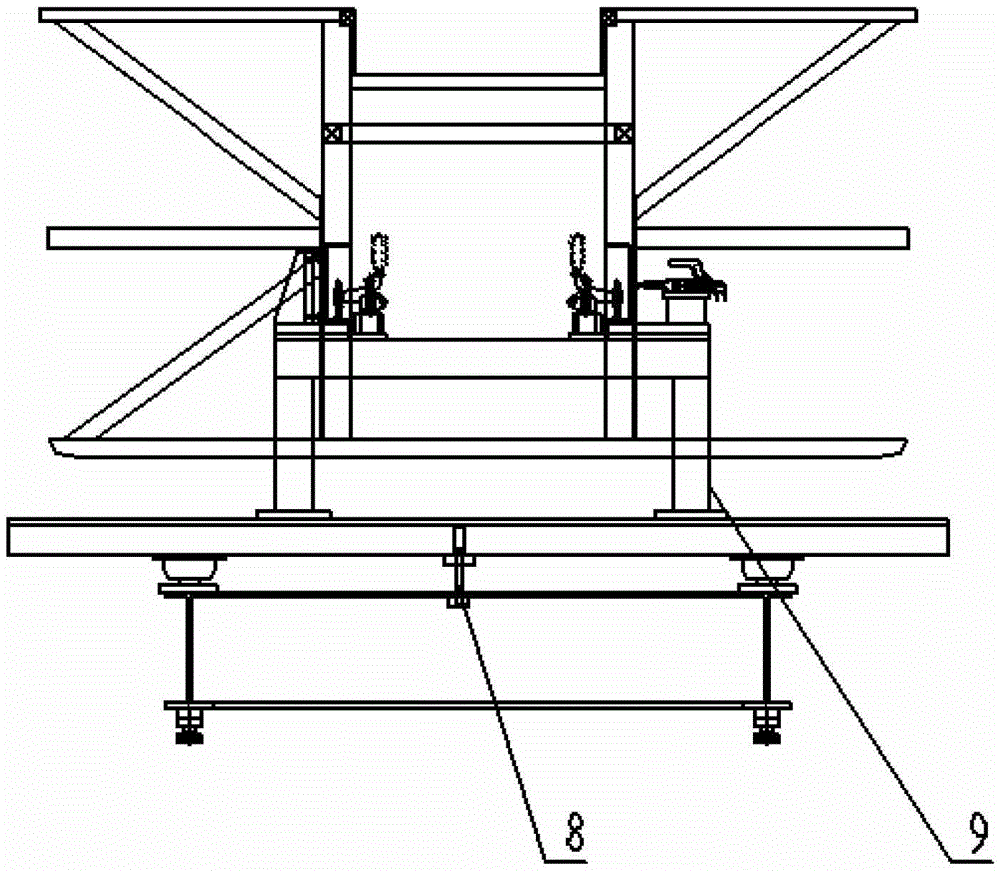

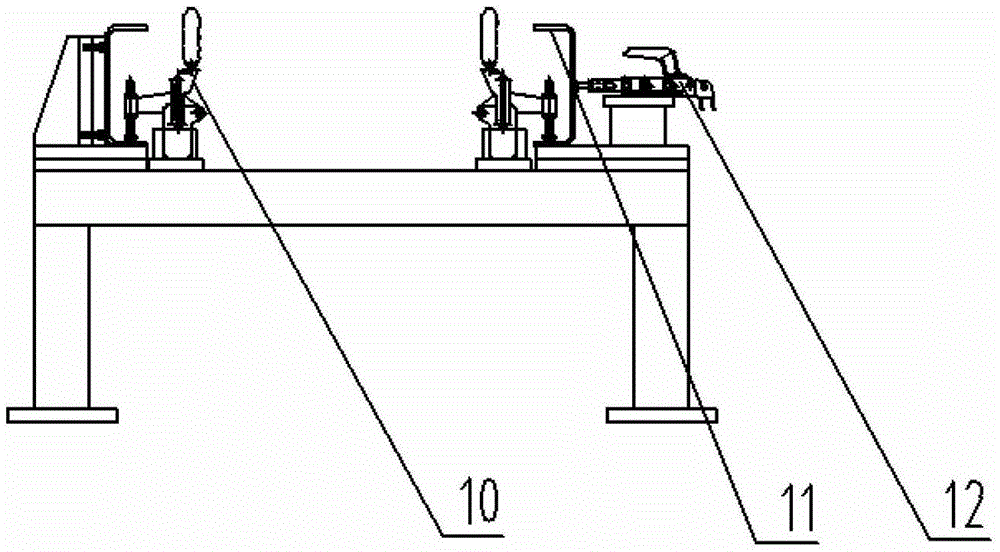

[0028] Such as Figure 1-8 As shown, a universal welding fixture suitable for the manufacture of full load-bearing chassis includes a fixed workbench 1 and 6 movable assembly welding bases (movable assembly welding base a2, movable assembly welding base b3, movable assembly welding base c4, movable group welding base d5, movable group welding base e6, movable group welding base f7), 12 positioning units; the described 6 movable group welding bases are dispersedly arranged on the fixed workbench 1, and the described 12 positioning units Set two by two on 6 movable group welding bases; according to the shape and size of the workpiece, move the movable group welding base, and match the positioning unit to fix the workpiece on the fixed workbench for welding.

[0029] Such as Figure 4-5 As shown, the fixed workbench includes a steel plate 14 as a worktable surface, a linear linear slide rail 13 arranged on the steel plate 14, and a large section steel 15 and an adjustment block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com