Selective adsorbent for caesium and preparation method of selective adsorbent

An adsorbent and selective technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, radioactive purification, etc., can solve problems such as being unsuitable for fixed bed operation, and achieve good adsorption effect, high selectivity, and large adsorption capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (a) Dissolve 15.5g of nickel sulfate and 12.66g of potassium ferrocyanide in 100mL and 50mL of deionized water, respectively, and continue to stir and react under ice bath conditions. After the precipitation is complete, let it stand for 12 hours, and then separate it by centrifugation. After fully washing with deionized water, dry at 70°C to obtain potassium nickel ferrocyanide, and grind it into a fine powder;

[0026] (b) Disperse 4.4 g of the prepared potassium nickel ferrocyanide powder evenly in 125 mL of acetic acid (1%) solution with a chitosan concentration of 3.5% (mass concentration). The mixed solution was ultrasonically treated for 10 minutes to fully dissolve the chitosan, and stirred at room temperature for 2 hours to obtain the water phase required by the reverse suspension method;

[0027] (c) Measure 130ml of aviation kerosene, add 0.8mL of Span 80, and stir well to obtain the oil phase required by the inverse suspension method.

[0028] (d) At a wate...

Embodiment 2

[0033] Get the chitosan-potassium ferrocyanide nickel-cesium selective adsorbent 0.01g obtained in Example 1, and treat Cs with constant temperature oscillation at 30° C. + A solution with an initial concentration of 10mg / L. Table 1 is solution Cs + Residual concentration, adsorbent adsorption Cs + Quantities change over time.

[0034] Table 1 The effect of adsorption time on the adsorption of Cs by chitosan-nickel potassium ferrocyanide + Impact

[0035] time (h)

[0036] The data in Table 1 show that the adsorption rate gradually decreases with the increase of adsorption time. The adsorption amount changes little after about 5 hours, and the adsorbent tends to be saturated to reach adsorption equilibrium, and the equilibrium adsorption capacity is about 37mg / L.

Embodiment 3

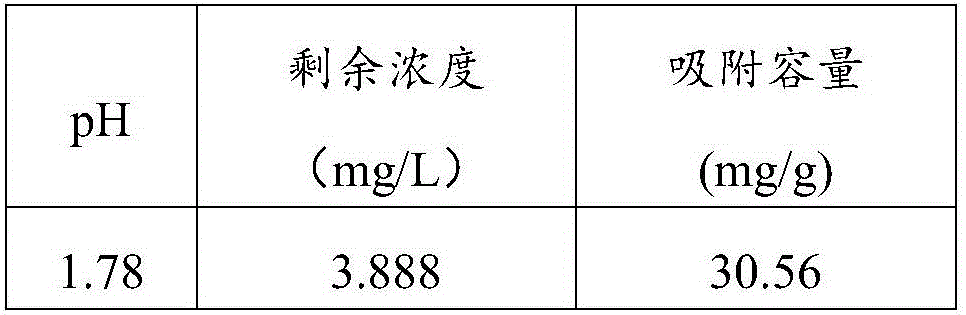

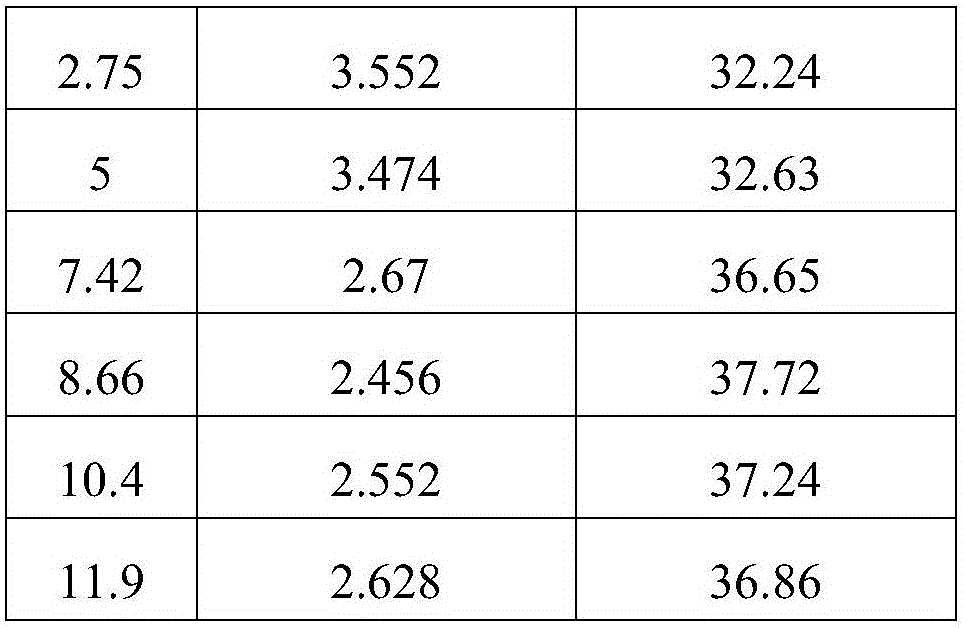

[0038] Adopt the method identical with embodiment 2 to process containing Cs + For the aqueous solution, the adsorption time was uniformly 7h, and the pH value of the solution was changed. The experimental results are shown in Table 2.

[0039] Table 2 pH value on the adsorption of Cs by chitosan-nickel potassium ferrocyanide + Impact

[0040]

[0041]

[0042] The data in Table 2 show that the adsorption capacity of chitosan-nickel potassium ferrocyanide increases with the increase of pH, but the change range is not large. The pH range with the best adsorption effect is 7~9. The adsorption capacity is 36.65mg / L~37.72mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com