A multi-component VOCs adsorption condensation recovery device

A condensate recovery, multi-component technology, applied in separation methods, dispersed particle separation, gas treatment, etc., can solve the problems of inability to separate and collect multi-component VOCs, waste heat not effectively used, and low adsorption capacity of adsorbents, etc., to achieve Reduce energy consumption, improve adsorption and purification capacity, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

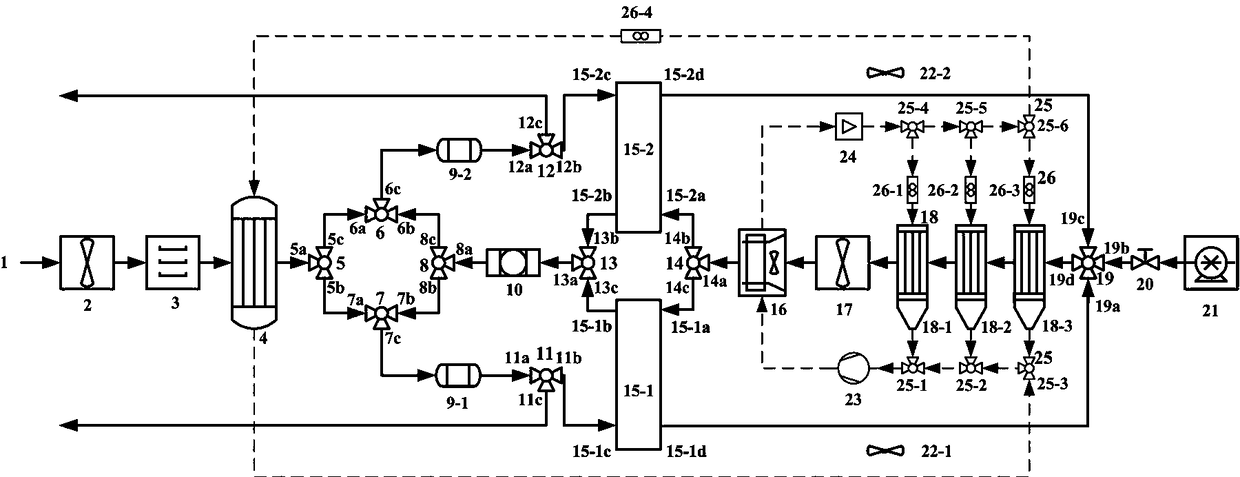

[0017] Attached below figure 1 The present invention will be described in detail with specific embodiments, and the following description is only for demonstration and explanation, and does not limit the present invention in any form.

[0018] The multi-component VOCs adsorption and condensation recovery device in this embodiment includes an adsorption system, a VOCs desorption condensation collection system and a refrigeration system, and an adsorbent fixed bed 9-1 (or adsorbent Fixed bed 9-2) is the core component, and it is an adsorption system that precools and dehumidifies the exhaust gas; it is connected to the other output end of the precooler 4, which is used to adsorb the saturated adsorbent while the adsorption system is adsorbing The fixed bed 9-2 (or adsorption fixed bed 9-1) is a VOCs desorption condensation collection system for desorption recovery. The VOCs desorption condensation collection system is also connected to the refrigeration system that provides cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com