Method for stabilizing heat exchange efficiency and capacity of thin plate of cut-tobacco drier

A technology of heat exchange efficiency and silk drying machine, which is applied in the fields of tobacco, tobacco preparation, and tobacco treatment, and can solve the problems of reducing the heat transfer performance of thin plates and the reduction of heat exchange capacity of thin plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

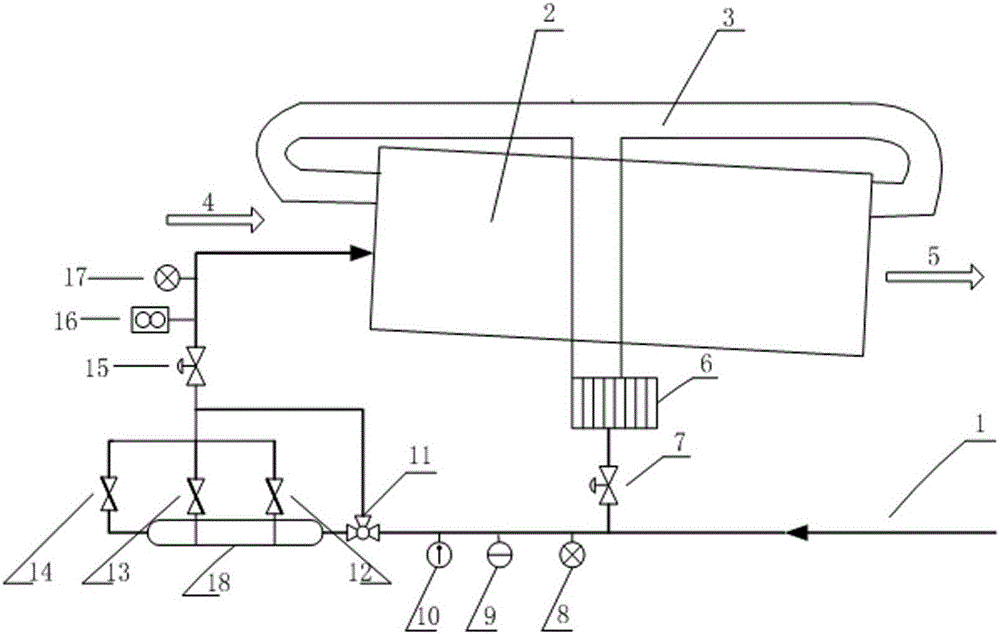

[0029] In order to better describe the above purpose and features of the present invention, the technical solutions of the present invention will be described below in conjunction with the accompanying drawings.

[0030] In the following specific embodiments, many specific details are described in order to fully understand the present invention, but the present invention can also be implemented in other ways that are different from those described here. Therefore, the present invention is not limited to the specific embodiments disclosed below. limits.

[0031] The specific implementation is as follows:

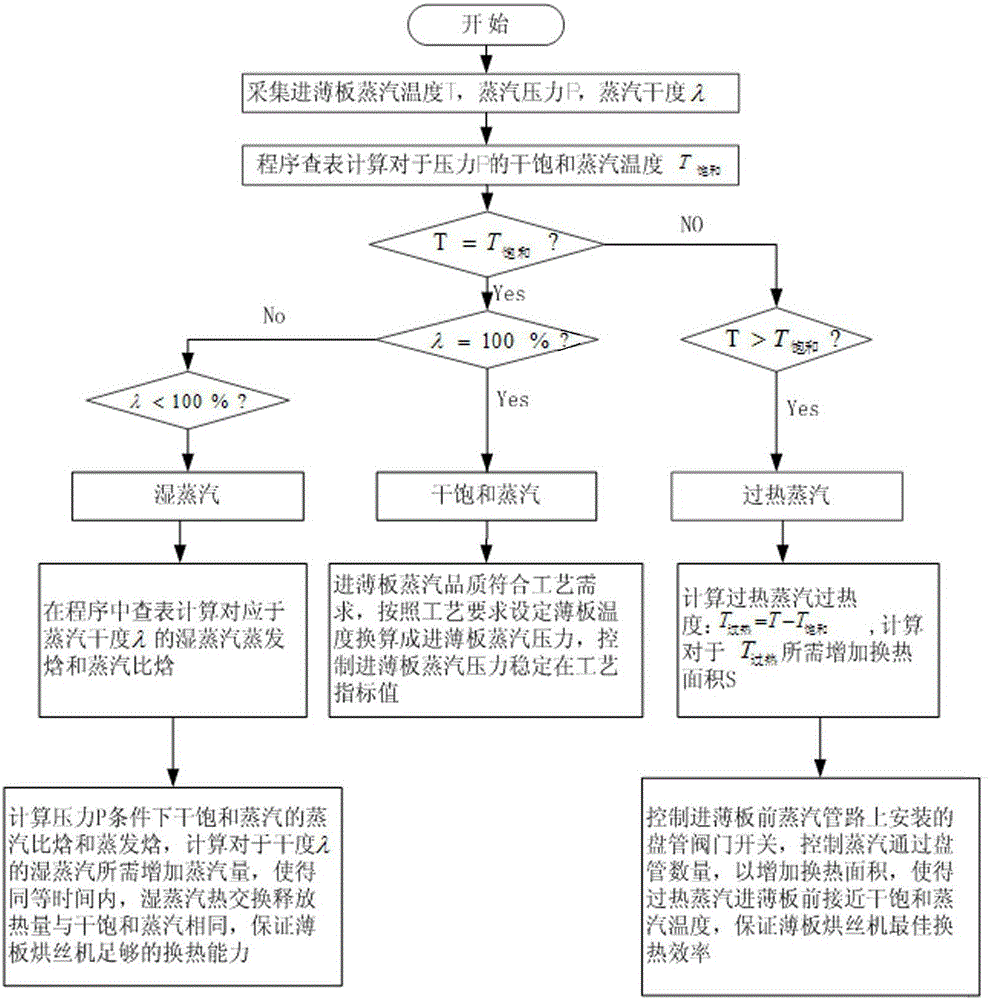

[0032] (1) Collect the values of steam pressure, steam temperature and steam dryness of the incoming sheet

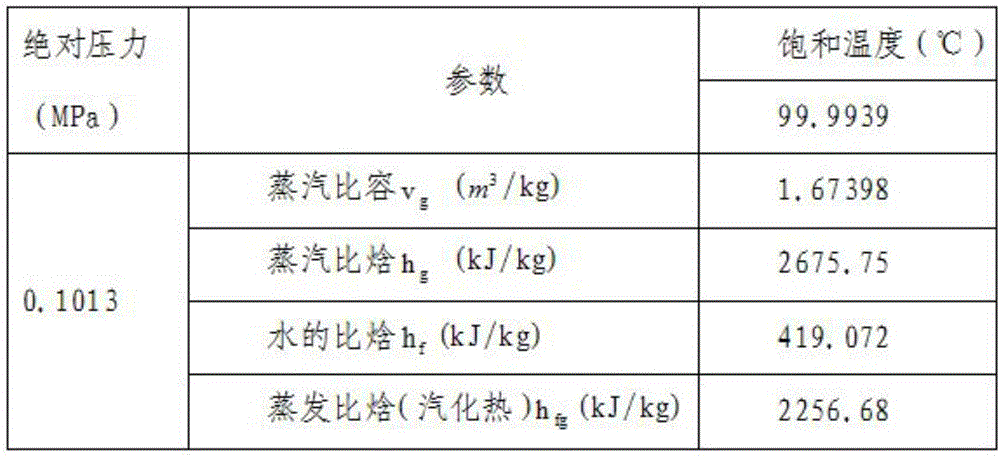

[0033] Install a steam pressure gauge 8, a thermometer 9, and a dryness meter 10 on the steam pipeline of the silk dryer into the thin plate, stabilize the steam pressure 8 entering the thin plate through a pressure reducing valve or a controller, and collect the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com