Microtubes made of carbon nanotubes

A technology of carbon nanotubes and microtubes, applied in the field of microtubes, can solve the problems of unavailability of tubular fuel cells and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The preparation of suspensions of carbon nanotubes is well known to those skilled in the art, and numerous procedures are suitable for the manufacture of CNT suspensions suitable for the manufacture of microtubes made of carbon nanotubes. In general, the preparation of CNT suspensions involves several main steps briefly described here. Before preparing the suspension, the CNTs are pretreated to remove carbonaceous impurities and catalyst residues (Fe, Co, Ni, Au, Pd, Ag, Pb, Mn, Cr, Ru, Mo, Cu, ). Next, the modification of the carbon nanotubes described previously can be performed. This step is followed by the preparation of the suspension. A large number of solvents are known for the preparation of CNT suspensions. A few examples are: isopropylalcohol (IPA), N-methylpyrrolidone (NMP), N,N-dimethylformamide (N,N-dimethylformamide, DMF) and water. Prepare water using suitable surfactants such as Triton X-100, sodium dodecylbenzenesulfonate (NaDDBS), sodium dodecylsul...

example 1

[0067] Example 1: Free-standing microtubes made from multi-walled carbon nanotubes

[0068] Multi-walled carbon nanotubes (MWCNTs) (>95% purity, Sigma-Aldrich) with an outer diameter of 6-9 nm and a length of 5 μm were used as received without any pretreatment. An aqueous suspension of pristine CNTs was prepared as follows: 1 gram of CNTs was mixed with 10 g of Triton-X100 (laboratory grade, Sigma-Aldrich) surfactant in 1 liter of distilled water (18 m'Ω), magnetically stirred for 30 minutes and Sonication was continued for 3 hours in 1 liter Duran bottles (75% amplitude, UP200S, Hielscher), which were submerged in an ice bath to prevent overheating of the suspension. Internal → external filtration using MWCNT suspensions via polypropylene (polypropylene, PP) microfiltration (microfiltration, MF) hollow fiber membranes (with 46.5 cm length and 1.8 ± 0.15 and 0.45 ± 0.05 mm inner diameter and wall thickness, respectively, PPS6 / 2 , Accurel) to prepare from MWCNT ( Figure 5 ) ...

example 2

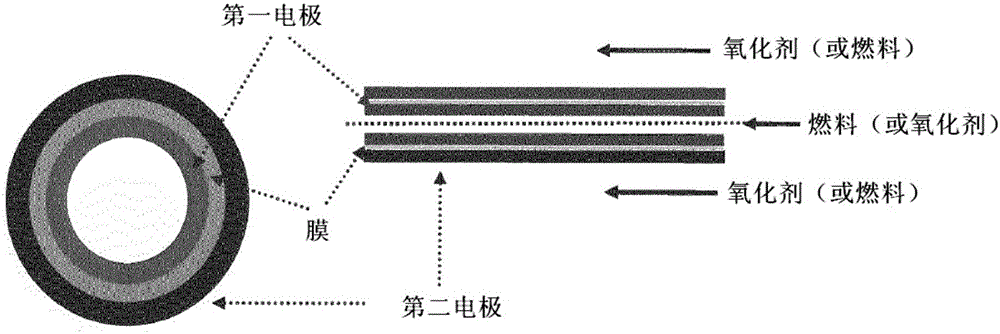

[0080] Example 2: Membrane Electrode Assembly with Proton Exchange Membrane and Microtubes Made of Carbon Nanotubes

[0081] Microtubes made of multi-walled carbon nanotubes with an outer diameter of 836 (±0.7%) μm and a wall thickness of 274.4 (±3.6%) μm were coated with Nafion117 solution (5%, Aldrich) by brushing and air-drying . Thermal curing was performed in a vacuum oven at 150° C. for 6 hours. Figure 11 A cross-sectional image of a membrane electrode assembly recorded using a scanning electron microscope is shown.

[0082] The resulting thickness of the film was approximately 15 μm. The MEA was tested for leakage with 5M sulfuric acid which was pumped through the tubular MEA using a peristaltic pump at a flow rate of 30ml / min. No visible loss of solution through the MEA was detected. This membrane electrode assembly can be assembled with secondary microtubular CNT electrodes using electrophoretic deposition methods. Alternatively, individually fabricated microtub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com