Positive electrode containing nitrogen-doping graphene, preparation method of positive electrode and lithium battery adopting positive electrode

A nitrogen-doped graphene and graphene technology, applied in the field of electrochemistry, can solve problems such as the difference in the mechanism of action, the influence of battery performance, and the effect of different functions, and achieve the effect of high catalytic activity and improved electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] The preparation method of the positive electrode sheet: mixing acetylene black, polytetrafluoroethylene accounting for 8% of the mass of the acetylene black, nitrogen-doped graphene accounting for 1% of the mass of the acetylene black and absolute ethanol, then heating and foaming, and roll forming to obtain positive plate.

[0070] A lithium / thionyl chloride battery is made by using the positive electrode sheet of this embodiment, and the injected electrolyte is 1.5 mol·L -1 LiAlCl 4 / SOCl 2 . Use the discharge test system to test the battery at room temperature at 25mA·cm -2 discharge to 2.0V under the condition of the current density.

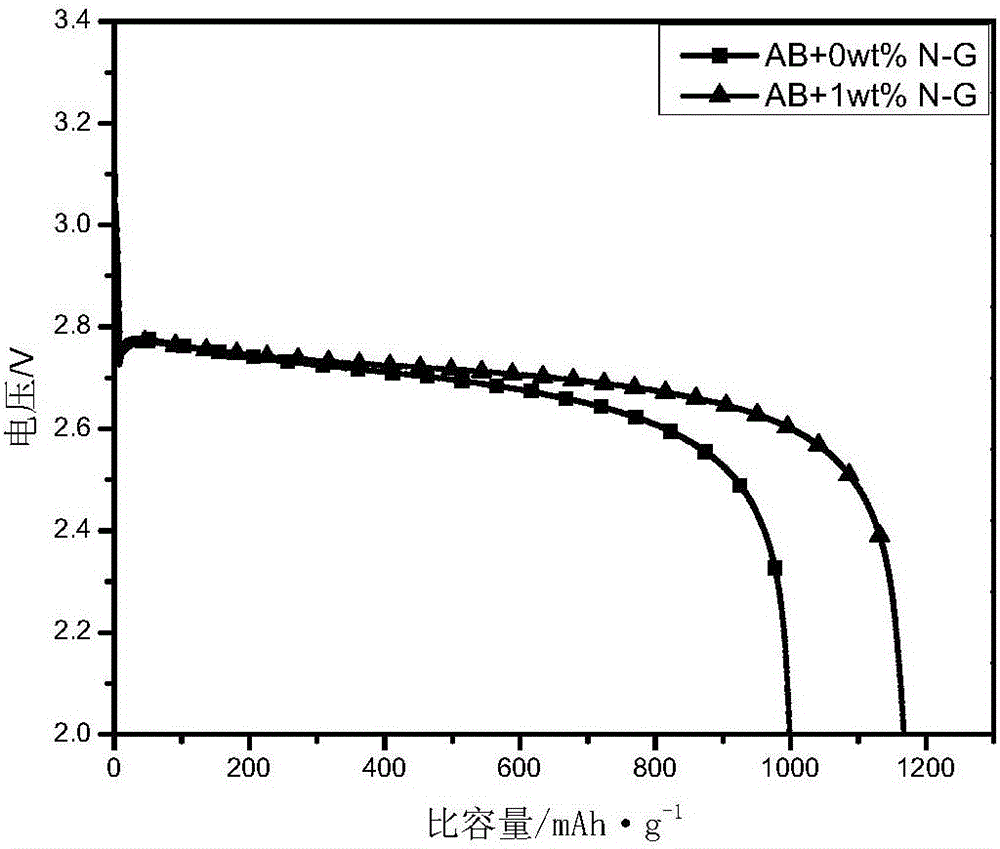

[0071] The discharge results of the lithium / thionyl chloride battery obtained in this example are as follows figure 1 . from figure 1 It can be seen that the discharge capacity of the battery without catalyst is 1000mAh g -1 , the battery with 1% nitrogen-doped graphene catalyst (N-G) achieves a discharge capacity of 1178mAh g...

Embodiment 2

[0073] Except that the addition amount of nitrogen-doped graphene accounts for 3% of the mass of acetylene black, other preparation and detection methods and conditions are the same as those in Example 2.

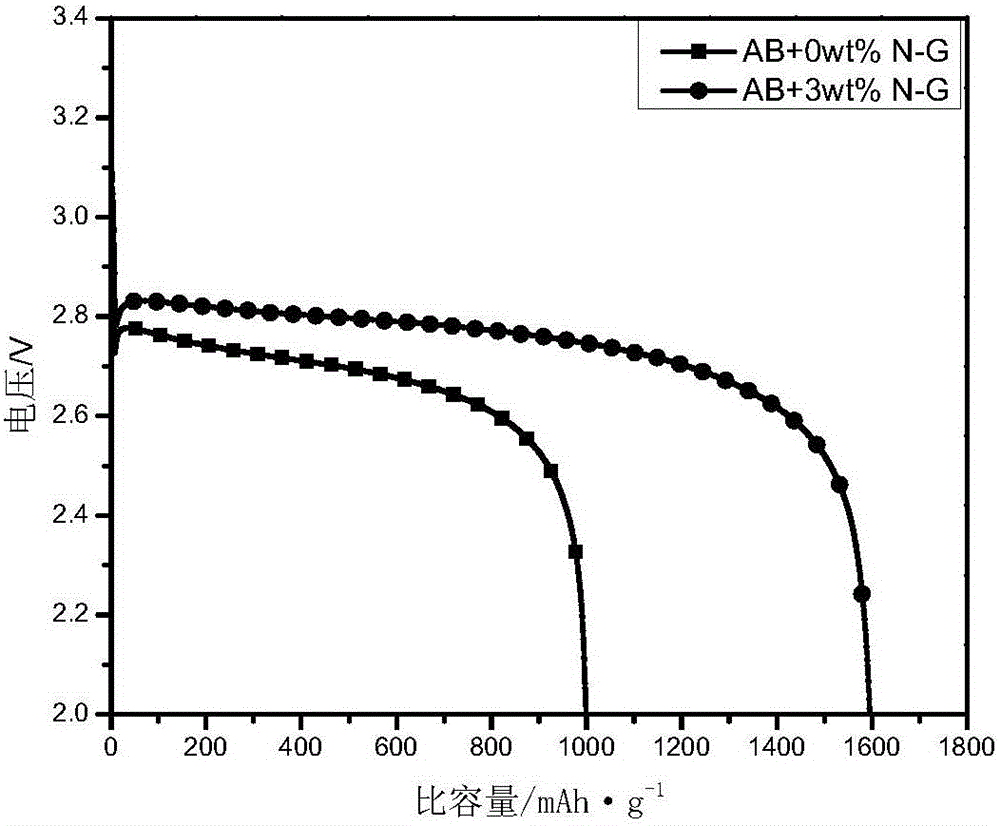

[0074] The discharge results of the lithium / thionyl chloride battery obtained in this example are as follows figure 2 . from figure 2 It can be seen that the discharge capacity of the battery without catalyst is 1000mAh g -1 , the discharge midpoint voltage is 2.68V; the discharge capacity of the battery containing 3% N-G catalyst is as high as 1600mAh g -1 , the midpoint voltage is as high as 2.79V, the catalytic effect is obvious, and the discharge capacity is increased by 600mAh g -1 , the midpoint voltage is increased by 110mV.

Embodiment 3

[0076] Except that the addition amount of nitrogen-doped graphene accounts for 5% of the mass of acetylene black, other preparation and detection methods and conditions are the same as those in Example 1.

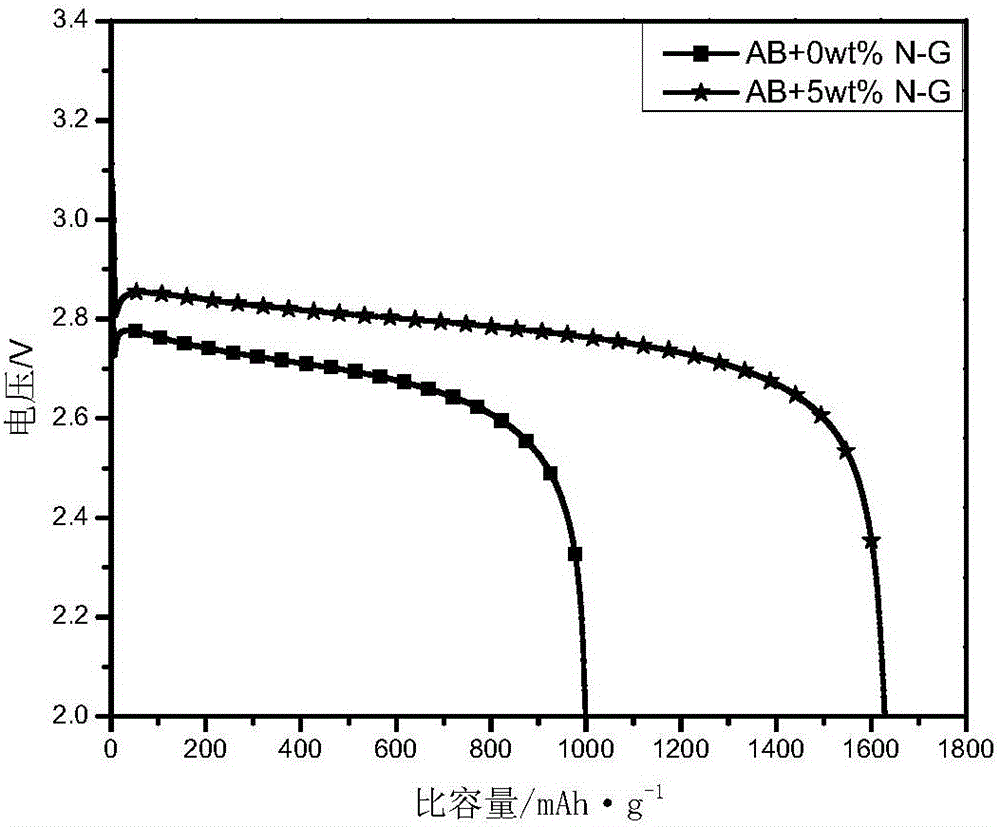

[0077] The discharge results of the lithium / thionyl chloride battery obtained in this example are as follows image 3 . from image 3 It can be seen that the discharge capacity of the battery without catalyst is 1000mAh g -1 , the discharge midpoint voltage is 2.68V; the discharge capacity of the battery containing 5% N-G catalyst is as high as 1640mAh·g -1 , the midpoint voltage is as high as 2.81V, the catalytic effect is very obvious, and the discharge capacity is increased by 640mAh g -1 , the midpoint voltage is increased by 130mV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com