Engine cooling system with EGR system and control method thereof

A cooling system and engine technology, applied in engine cooling, coolant flow control, engine components, etc., can solve the problems of EGR exhaust gas overcooling and EGR system cooling energy consumption, and achieve the effect of saving cooling energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

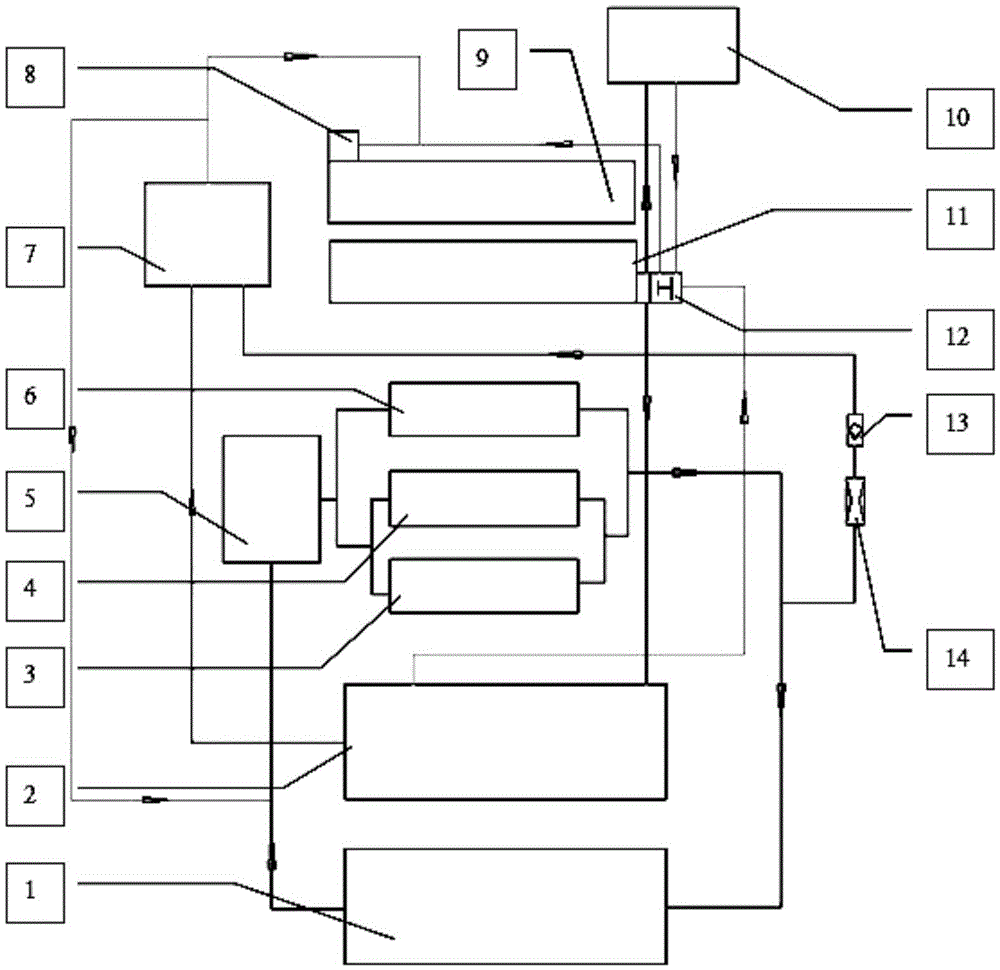

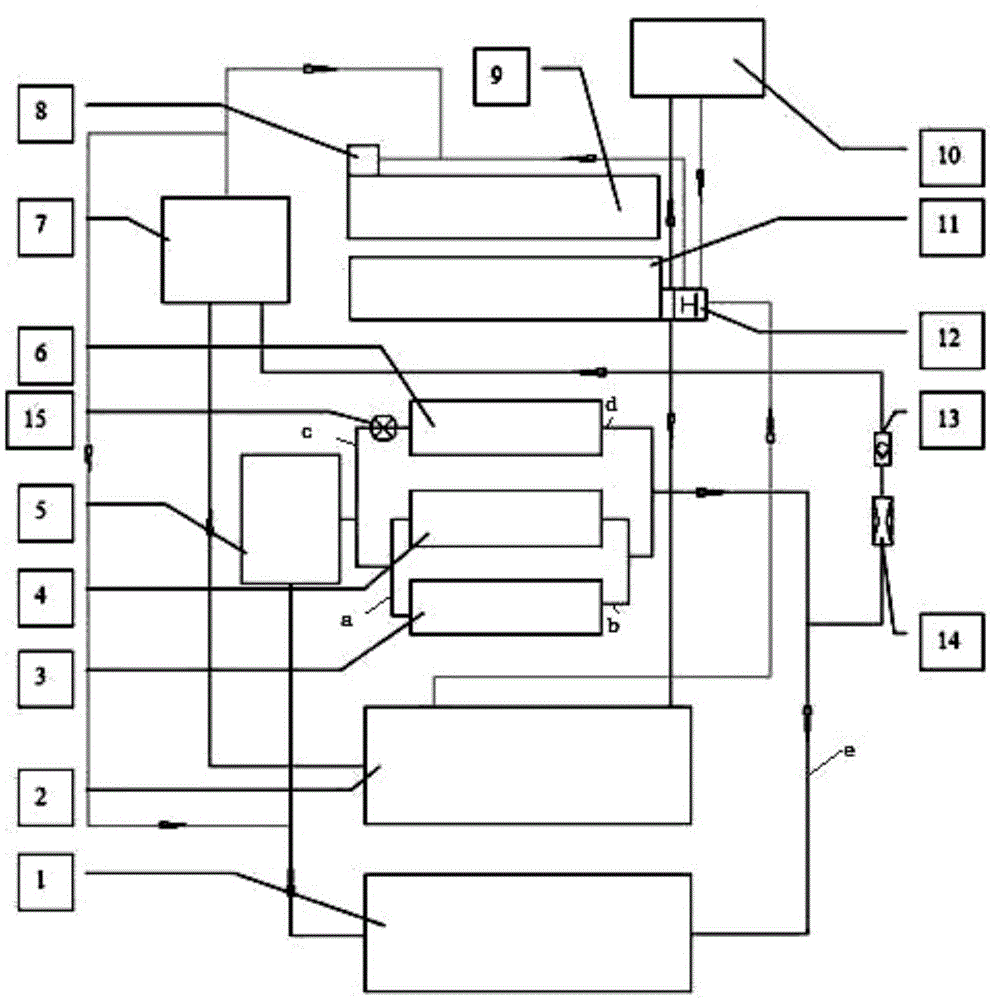

[0030] like image 3 As shown, the engine cooling system in this embodiment with EGR system, air intake integrated intercooler and supercharging system includes 1. Low temperature radiator 2. High temperature radiator 3. Intake integrated intercooler 4. Supercharging system 5. Electronic water pump 6 .EGR system 7. Expansion pot 8. Water pump 9. Cylinder body 10. Warm air 11. Cylinder head 12. Thermostat 13. One-way valve 14. Throttle valve 15. Solenoid valve, rubber tubes and The three-way pipe is connected, and the cooling flow direction is: the electronic water pump 5 to the parallel EGR system 6, the supercharging system 4, the air intake integrated intercooler 3, and then to the low-temperature radiator 1. Wherein, the electronic water pump is connected to the EGR system through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com