Electro-deposition foam metal for phase change cold accumulation and preparation method thereof

A foam metal, phase change cold storage technology, applied in the field of heat and mass transfer, can solve the problems of large subcooling difference, large contact thermal resistance, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

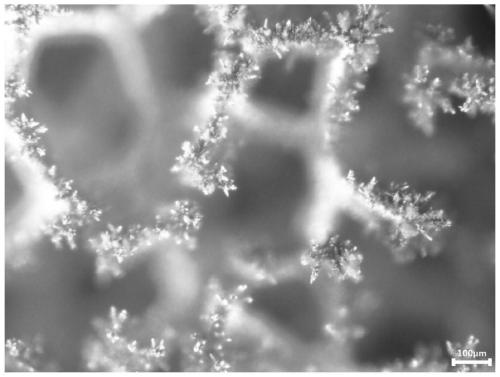

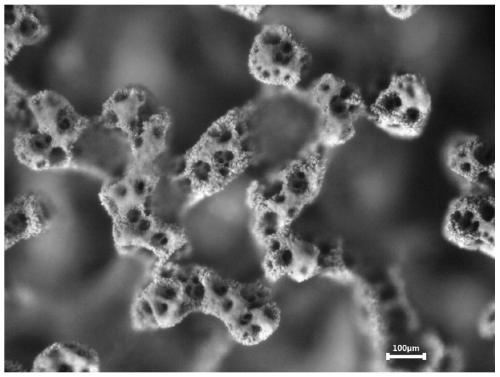

[0051] In order to prepare the above-mentioned electrodeposited metal foam 401 for phase change cold storage, this embodiment also provides a preparation method for electrodeposited metal foam 401 for phase change cold storage, including:

[0052] Step S1: electrochemically depositing the micro-nano structure on the surface of the metal foam 201;

[0053] Step S2: attaching the phase change cold storage material 402 to the surface of the metal foam 201 deposited with the micro-nano structure.

[0054] see again Figure 4 , in order to obtain electrodeposited metal foam 401 deposited with micro-nano structures through step S1, it can be used Figure 4 The shown setup performs electrochemical deposition operations.

[0055] In detail, see Figure 4 , the preparation device for preparing the electrodeposited metal foam 401 includes an electrolytic container 101 , a wire 203 and a power source 204 . Wherein, the electrolytic container 101 is filled with an electrolytic solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com