A kind of flame-retardant polyester yarn and the sofa cloth made of the polyester yarn

A flame retardant polyester and yarn technology, applied in the field of sofa release, can solve the problems of melt droplets, no flame retardancy, disasters, etc., and achieve the effect of good elasticity and good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

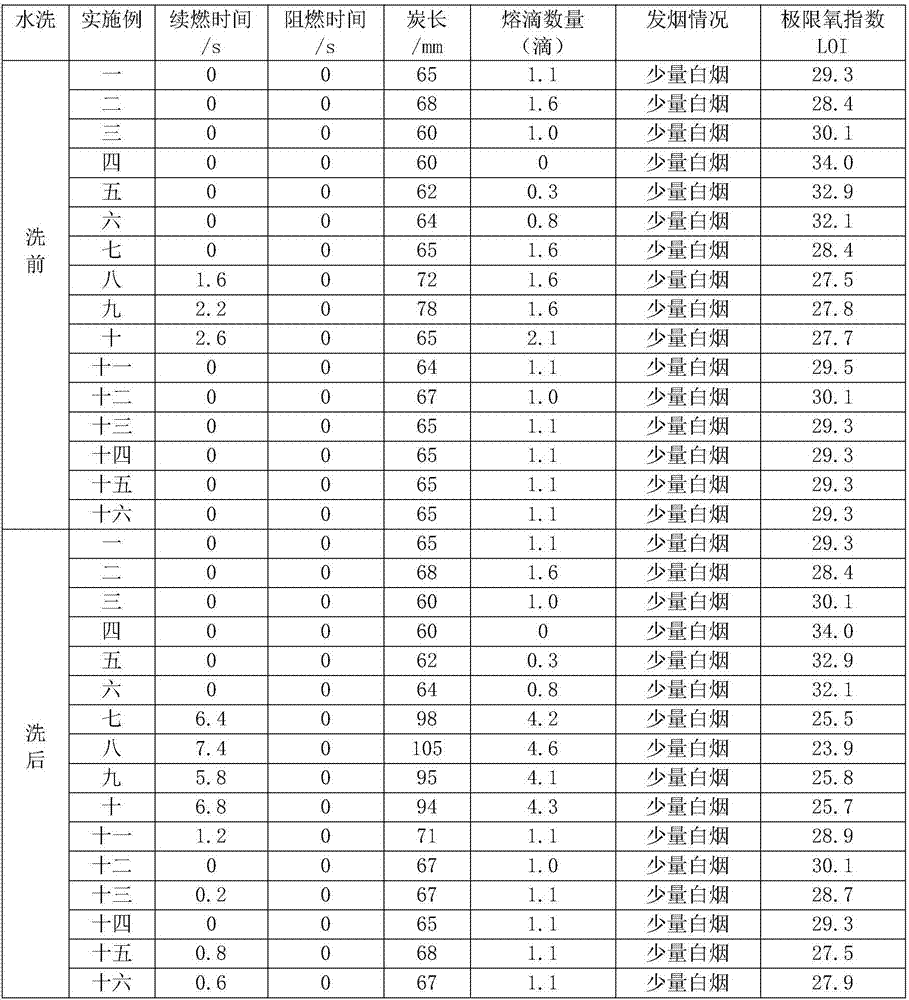

Embodiment 1

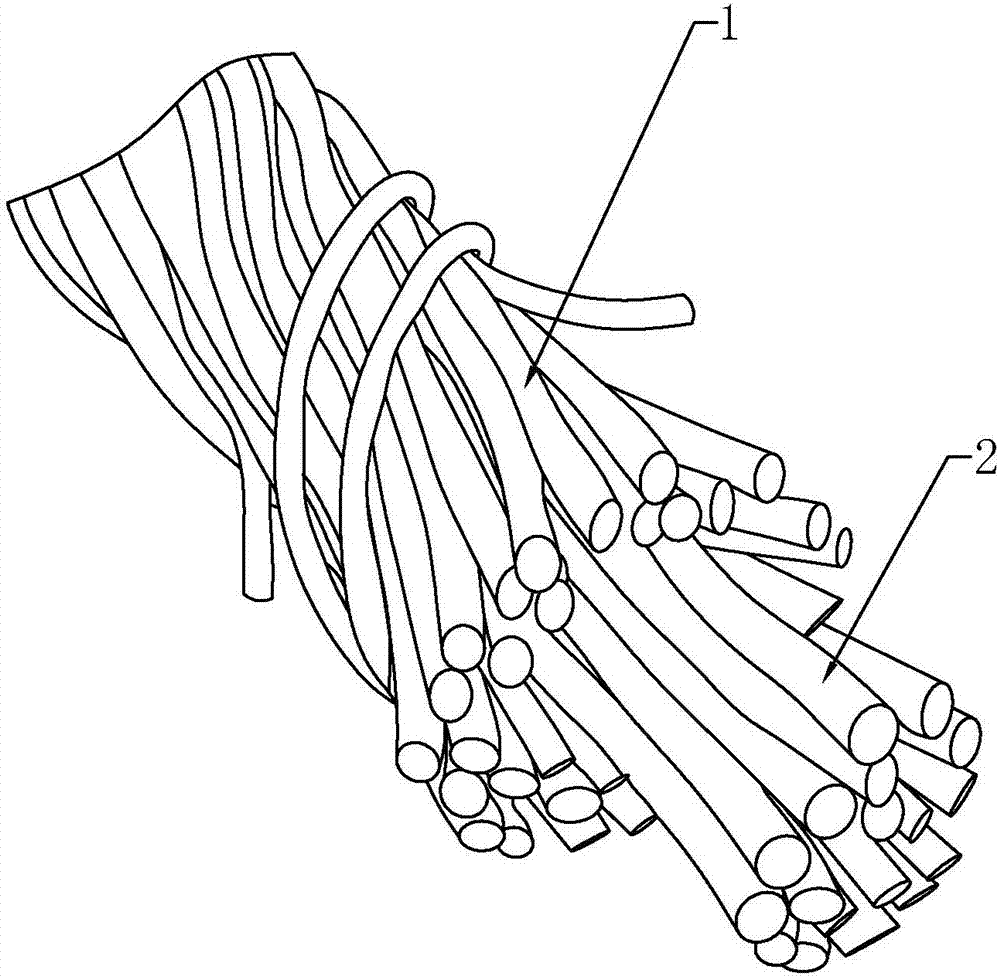

[0038] A flame-retardant polyester yarn includes a metal core yarn 2 and a flame-retardant sheath yarn 1. The metal core yarn 2 is stainless steel fiber or silver fiber. In this embodiment, the metal core yarn 2 is selected to use stainless steel fiber from the viewpoint of cost and practical performance. In this embodiment, the polyester yarn is made of 80 parts by weight of the flame-retardant sheath yarn 1 as short filaments, and 20 parts by weight of the metal core yarn 2 as the filament core. The flame-retardant polyester yarn is also coated with Flame retardant coating agent, the coating weight of the flame retardant coating agent is 35% of the polyester yarn weight.

[0039] Among them, the flame-retardant sheath yarn 1 is made by blending 70 parts by weight of flame-retardant polyester fiber and 30 parts by weight of poly(metaphenylene isophthalamide) fiber. The flame-retardant additives in the flame-retardant polyester fiber account for The mass weight percentage content...

Embodiment 2

[0055] It is basically the same as Embodiment 1, with the only difference: In this embodiment, the polyester yarn is made of 90 parts by weight of flame-retardant sheath yarn 1 as short filaments and 10 parts by weight of metal core yarn 2 as filament core.

Embodiment 3

[0057] It is basically the same as the first embodiment, except that the coating weight of the flame-retardant coating agent in this embodiment is 40% of the polyester yarn weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com