A carbon fiber reinforcement process for corrosion and protection of petrochemical equipment

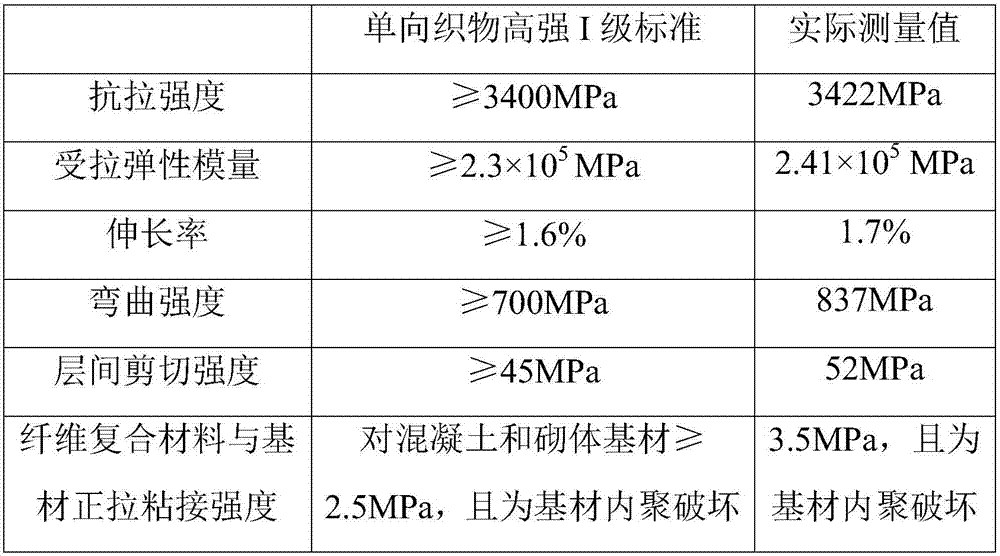

A petrochemical and carbon fiber technology, which is applied in the field of petrochemical pressure device repair, can solve the problems of reducing the tensile stress at the defect, reducing the stress of the pipe wall, and easy to fall off, so as to reduce the tensile stress, prevent galvanic corrosion, and process steps simplified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

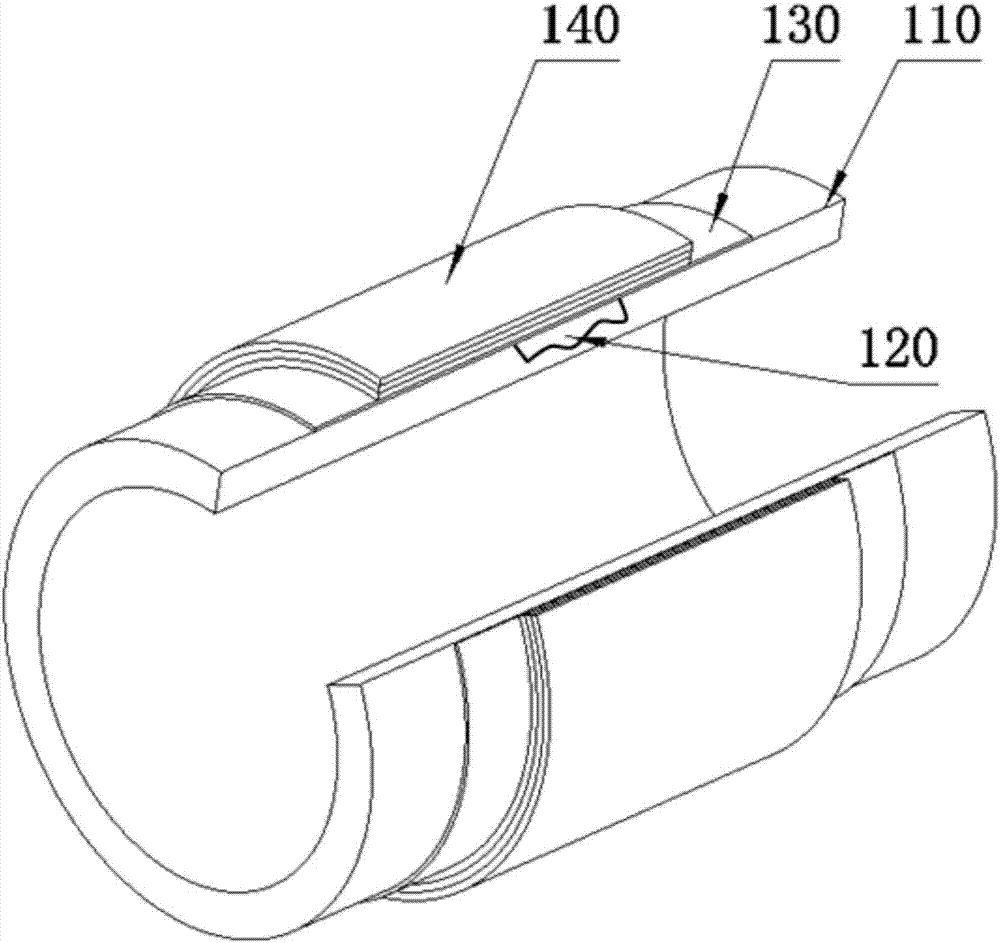

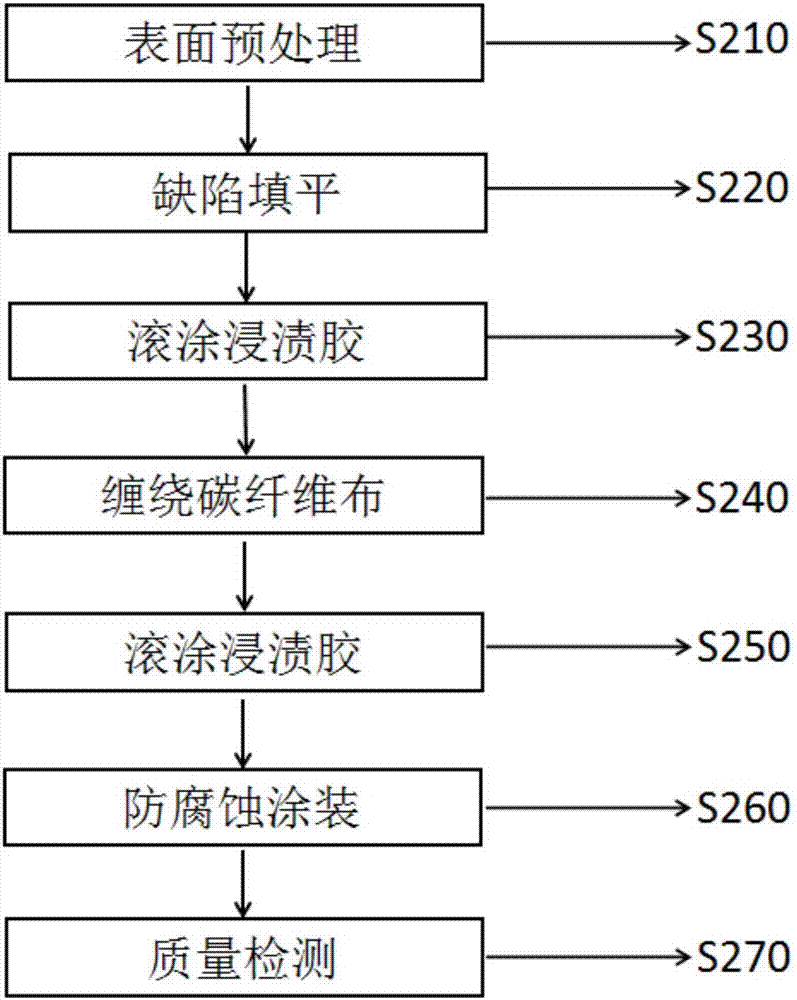

[0068] Step 1: Pre-treat the inner surface of the defect of the pressure vessel 110. The surface of the substrate should be fully polished without any attachments. If there are sharp edges and corners on the pasting part, it needs to be rounded. The minimum inner diameter is 20mm. The original anti-corrosion layer on the surface of the pipeline within 150mm in the two axial directions shall be completely removed by mechanical derusting. St2.5 level and above as stipulated in the "Assessment", at the same time, the depth of the defect is measured to be 6.5mm, the axial length of the defect is 78mm, the circumferential length of the defect is 15mm, and the wall thickness reduction is 36%. According to the ASME PCC-2-2011 standard The number of reinforcement layers of carbon fiber composite materials required in the calculation is 4 layers;

[0069] The second step is to use the special repair agent 120 (bottom epoxy resin glue) to fill and level the defect, and the special repai...

Embodiment 2

[0085]Step 1: Pre-treat the inner surface of the defect of the pressure vessel 110. The surface of the substrate should be fully polished without any attachments. If there are sharp edges and corners on the pasting part, it needs to be rounded. The minimum inner diameter is 20mm. The original anti-corrosion layer on the surface of the pipeline within 150mm in the two axial directions shall be completely removed by mechanical derusting. St2.5 level and above as stipulated in the "Assessment", at the same time, the depth of the defect is measured to be 8.6mm, the axial length of the defect is 93mm, the circumferential length of the defect is 55mm, and the degree of wall thickness reduction is 42%. According to the ASME PCC-2-2011 standard The number of reinforcement layers of carbon fiber composite materials required in the calculation is 6 layers;

[0086] The second step is to use the special repair agent 120 (bottom epoxy resin glue) to fill and level the defect, and the spec...

Embodiment 3

[0102] Step 1: Pre-treat the inner surface of the defect of the pressure vessel 110. The surface of the substrate should be fully polished without any attachments. If there are sharp edges and corners on the pasting part, it needs to be rounded. The minimum inner diameter is 20mm. The original anti-corrosion layer on the surface of the pipeline within 150mm in the two axial directions shall be completely removed by mechanical derusting. St2.5 level and above as stipulated in the "Assessment", at the same time, the depth of the defect is measured to be 7.9mm, the axial length of the defect is 56mm, the circumferential length of the defect is 23mm, and the wall thickness reduction is 37%. According to the ASME PCC-2-2011 standard The number of reinforcement layers of carbon fiber composite materials required in the calculation is 4 layers;

[0103] The second step is to use the special repair agent 120 (bottom epoxy resin glue) to fill and level the defect, and the special repai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com