Utilize transition metal phosphide catalyst to catalyze the method for hydrogenation of acetic acid to produce ethanol

A transition metal and catalyst technology, which is applied in the field of catalyzing acetic acid hydrogenation to produce ethanol by using transition metal phosphide catalyst, can solve the problems of high price and high production cost of ethanol, and achieves good activity stability, stable device operation time and environmental impact. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

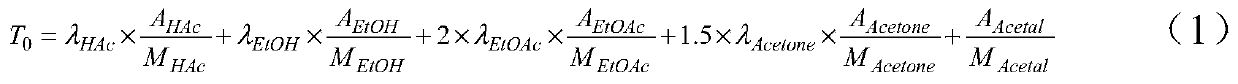

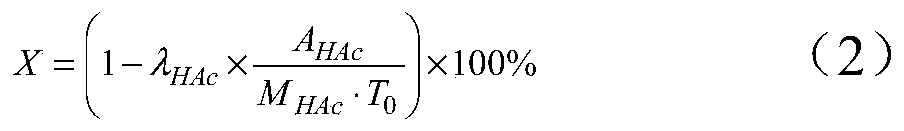

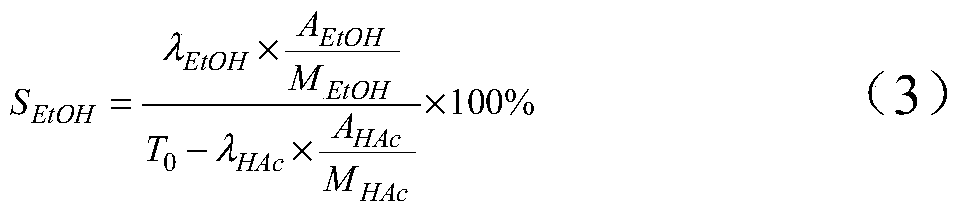

Method used

Image

Examples

Embodiment 1

[0044] Example 1: 1% Ni 2 P / γ-Al 2 o 3 Catalyst preparation

[0045] γ-Al 2 o 3 As a carrier (its specific surface area is 296m 2 / g), with Ni(H 2 PO 2 ) 2 ·6H 2 O as nickel source, with Ni(H 2 PO 2 ) 2 ·6H 2 O and NaH 2 PO 2 ·H 2 O as phosphorus source, weigh 10g of γ-Al 2 o 3 Carrier, consisting of 0.4g (1.3478×10 - 3 mol) of Ni(H 2 PO 2 ) 2 ·6H 2 O, 0.43g (4.057×10 -3 mol) of NaH 2 PO 2 ·H 2 O and distilled water to prepare 8.0 mL impregnation solution with nickel and phosphorus concentrations of 1.6848 × 10 -4 mol / mL, 8.4413×10 -4 mol / mL, the volume of the impregnating solution is equal to the volume of the maximum adsorbed water of the catalyst carrier, and the molar ratio of nickel and phosphorus atoms in the impregnating solution is 1:5. Carry out impregnation at room temperature according to the equal volume impregnation method, add 8.0mL impregnation solution dropwise to 10g carrier, and keep stirring. After the dropwise addition, it was ...

Embodiment 2

[0046] Example 2: 5% Ni 2 P / Al 2 o 3 Catalyst preparation

[0047] with Al 2 o 3 Carrier (its specific surface area is 302m 2 / g), Ni(H 2 PO 2 ) 2 ·6H 2 O nickel source, Ni(H 2 PO 2 ) 2 ·6H 2 O and NaH 2 PO 2 ·H 2 O phosphorus source to prepare supported catalyst. Weigh 10g of Al 2 o 3 , consisting of 2.0g (6.739×10 -3 mol) of Ni(H 2 PO 2 ) 2 ·6H 2 O, 1.43g (1.3492×10 -2 mol) of NaH 2 PO 2 ·H 2 O and distilled water to prepare 8.0 mL impregnation solution with nickel and phosphorus concentrations of 8.4238 × 10 -4 mol / mL, 3.3713×10 -3 mol / mL, the volume of the impregnating solution is equal to the volume of the maximum adsorbed water of the catalyst carrier, and the molar ratio of nickel and phosphorus atoms in the impregnating solution is 1:4. Carry out impregnation at room temperature according to the equal volume impregnation method, add 8.0mL impregnation solution dropwise to 10g carrier, and keep stirring. After the dropwise addition, it was ...

Embodiment 3

[0048] Example 3: 10% Ni 2 P / SiO 2 Catalyst preparation

[0049] Use porous silica gel carrier (its specific surface area is 480m 2 / g), Ni(H 2 PO 2 ) 2 ·6H 2 O nickel source, Ni(H 2 PO 2 ) 2 ·6H 2 O and NaH 2 PO 2 ·H 2 O phosphorus source to prepare supported catalyst. Weigh 10g of porous silica gel, from 4.0g (1.3478 × 10 - 2 mol) of Ni(H 2 PO 2 ) 2·6H 2 O, 1.43g (1.3492×10 -2 mol) of NaH 2 PO 2 ·H 2 O and distilled water to prepare 12 mL of impregnation solution with nickel and phosphorus concentrations of 1.1232 × 10 -3 mol / mL, 3.3707×10 -3 mol / mL, the volume of the impregnating solution is equal to the volume of the maximum adsorbed water of the catalyst carrier, and the molar ratio of nickel and phosphorus atoms in the impregnating solution is 1:3. Carry out impregnation at room temperature according to the equal volume impregnation method, add 12mL impregnation solution dropwise to 10g carrier, and keep stirring. After the dropwise addition, it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com