A kind of flame-retardant thermally modified wood and its preparation method

A thermal modification, wood technology, applied in wood treatment, wood impregnation, wood impregnation, etc., can solve the problem of no wood found

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Example 1 Preparation of modified nitrogen and phosphorus flame retardant

[0087] 1. Prepare polysilicate aluminum dihydrogen phosphate solution

[0088] 1A) Add aluminum dihydrogen phosphate powder to water, stir and dissolve uniformly to prepare aluminum dihydrogen phosphate solution, where the mass percentage concentration of the aluminum dihydrogen phosphate solution is 20%, that is, 400g aluminum dihydrogen phosphate is dissolved in every 100g In the water

[0089] 1B) Add sodium silicate to water, stir and dissolve uniformly to prepare a silicate solution, wherein the mass percentage concentration of the sodium silicate solution is 3%, that is, every 3g sodium silicate is dissolved in 97g water;

[0090] The concentration of aluminum dihydrogen phosphate solution in the present invention is 20%, and aluminum dihydrogen phosphate solutions with a concentration of 15-25% are all suitable for the present invention; the concentration of the silicate solution is 3% except for...

Embodiment 2

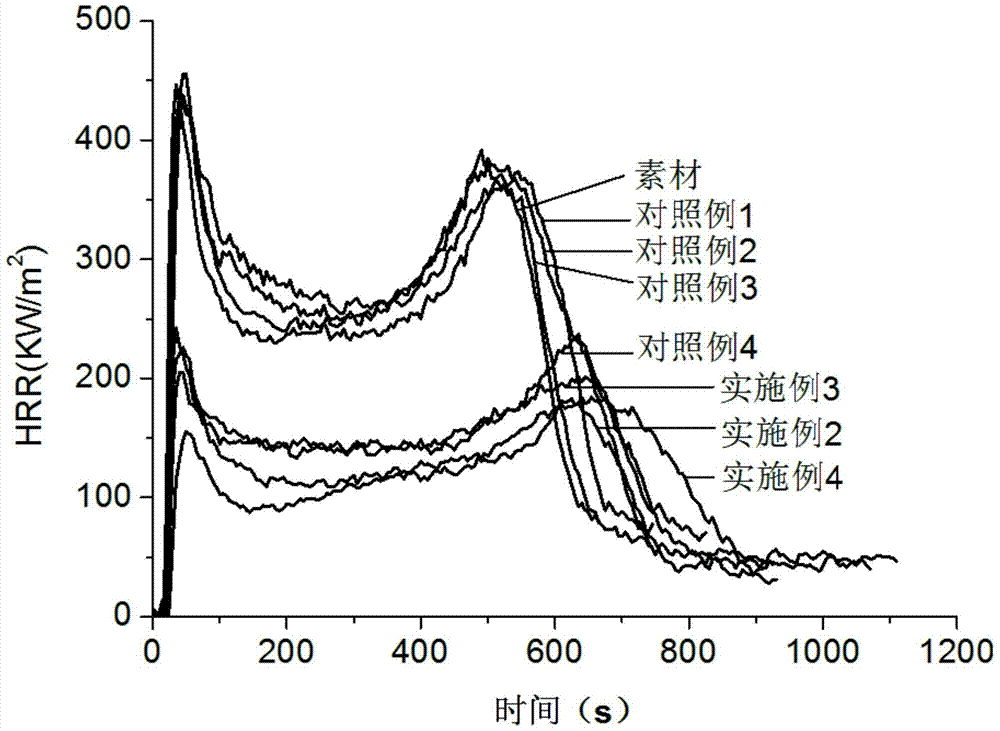

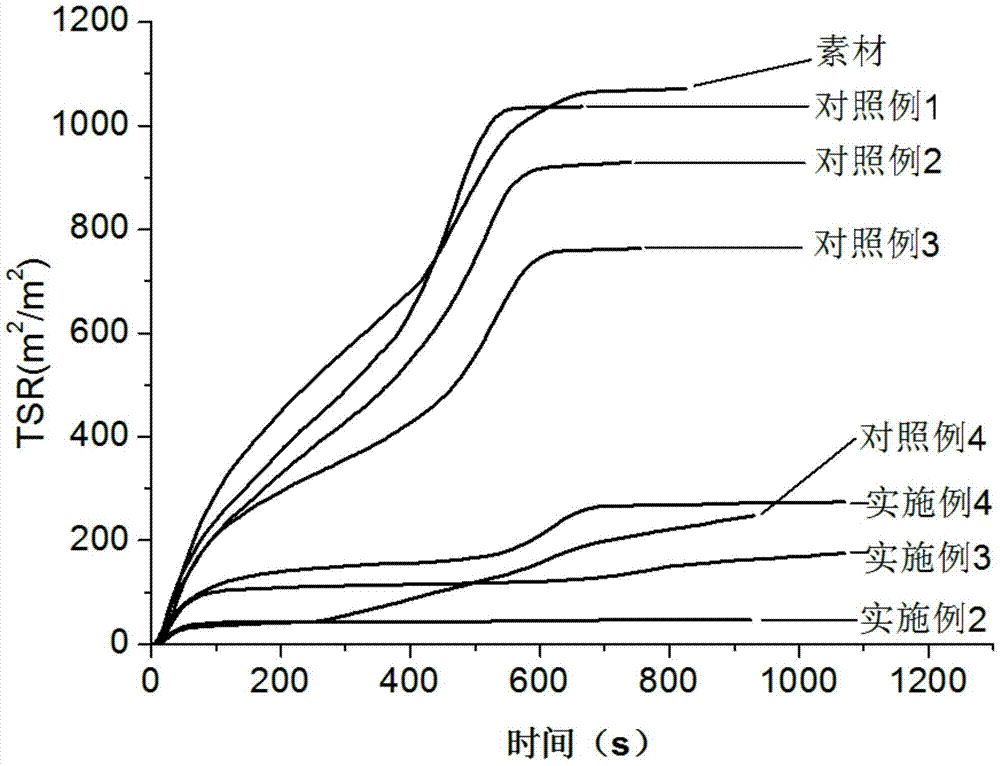

[0107] Example 2 Preparation of flame-retardant thermally modified wood

[0108] 1. Prepare modified flame retardant solution

[0109] The modified nitrogen and phosphorus flame retardant prepared in Example 1 was dissolved in water, stirred and dissolved uniformly to obtain a modified flame retardant solution. The mass percentage concentration of the modified flame retardant solution was 10%, that is, every 10g of modified nitrogen and phosphorus The flame retardant solution is obtained in 90g water.

[0110] In the embodiment of the present invention, the flame retardant solution with a mass percentage concentration of 10% is taken as an example for description, and other flame retardant solutions with a mass percentage concentration of 5-15% are all suitable for the present invention.

[0111] In addition to the modified nitrogen-phosphorus flame-retardant, the flame-retardant used in the impregnation treatment of the present invention is also applicable to the present invention. ...

Embodiment 3

[0127] Example 3 Preparation of flame-retardant thermally modified wood

[0128] 1. Prepare modified flame retardant solution

[0129] The modified nitrogen and phosphorus flame retardant prepared in Example 1 was dissolved in water, stirred and dissolved uniformly to obtain a modified flame retardant solution. The mass percentage concentration of the modified flame retardant solution was 5%, that is, every 5g of modified nitrogen and phosphorus The flame retardant solution is obtained in 95g water.

[0130] 2. Dipping treatment

[0131] 2-1) Vacuum impregnation treatment

[0132] Pour the flame retardant solution into the impregnating tank with fast-growing poplar wood, soak the wood completely, and connect the vacuum pump; turn on the vacuum pump for vacuum treatment to reduce the vacuum in the tank and keep it at -0.09MPa. Vacuum impregnation treatment is performed on the wood under pressure to obtain vacuum impregnated wood, wherein the volume ratio of the wood to the flame retard...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| dimensional stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com