Insulation package arrangement for insulating the interior of an aircraft fuselage

A technology for aircraft fuselage and packaging devices, which is applied in the field of fire-proof or fire-proof devices and isolation packaging devices, which can solve the problems of prolonging the fire-resistant time and melting of attachments, and achieve the effect of convenient evacuation and prolonged time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

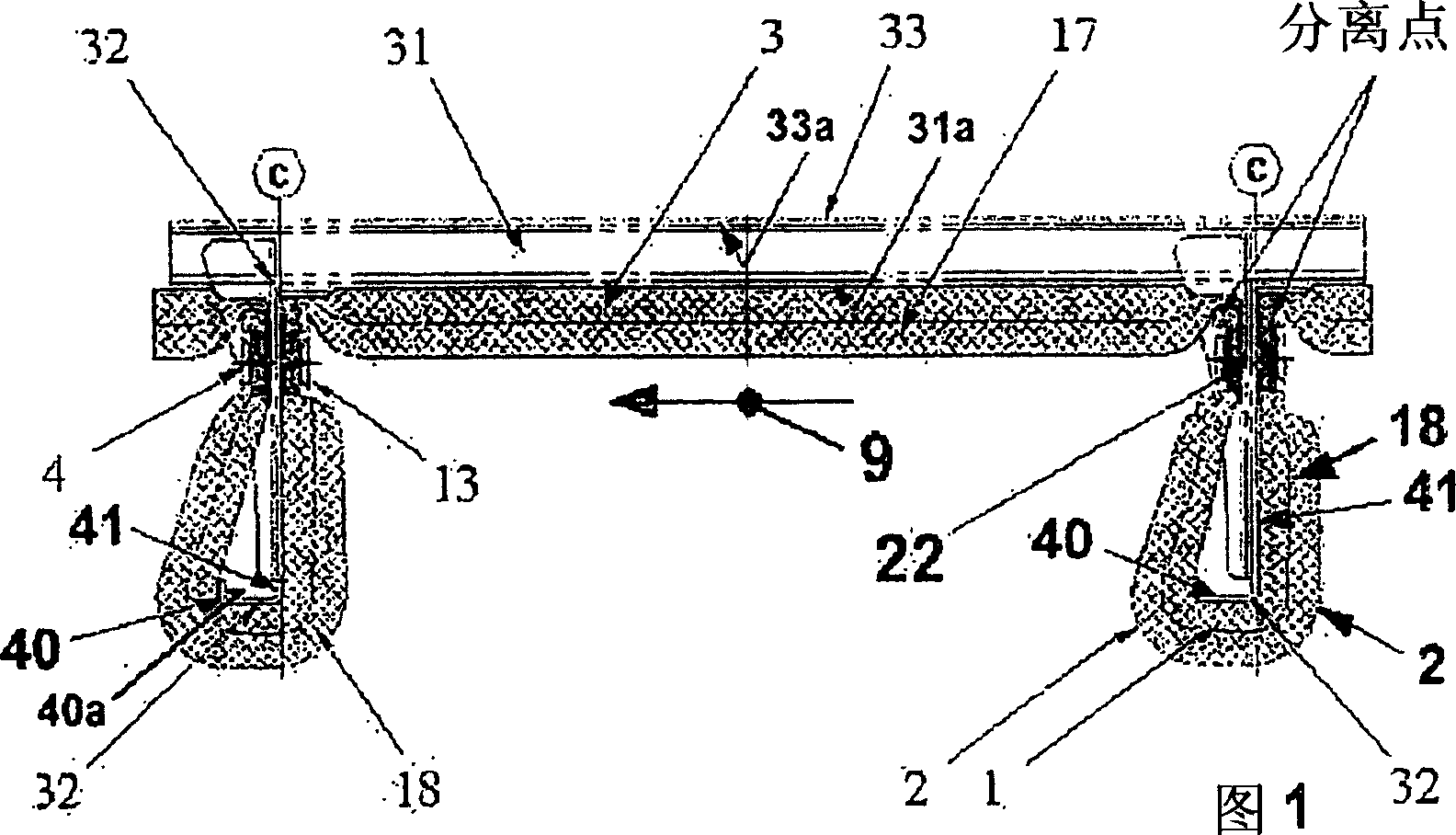

[0026] For an easier understanding of FIG. 1 , which shows a separator, it should be mentioned as an introduction that the structural element of the aircraft fuselage not only includes stringers 31 , but also ribs 32 , wherein with the aid of stringers The strips reinforce all the panels of the outer skin 33 of the aircraft fuselage structure, while the ribs are arranged (approximately) at a distance c perpendicular to the longitudinal axis 9 of the aircraft and are attached to the stringers 31 . A (so-called) rib support 40 is bonded to these ribs 32 at the non-attached end, the rib support 40 extending parallel to the longitudinal axis 9 of the aircraft, wherein the rib support (according to the present embodiment) 40 (unattached free) end is angled perpendicular to the longitudinal axis 9 of the aircraft.

[0027] FIG. 1 shows the insulation package 3 (of the fuselage insulation) in a position (near) on the outer skin 33 of the aircraft (with general reference characteristi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com