Diffusion Welding Method of Engine Sealing Structure

A diffusion welding and engine technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of easy oxidation, drumming, and peeling off blocks of the sealing coating, so as to avoid welding defects and facilitate welding , The effect of optimizing welding conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Follow the steps below to prepare the engine sealing structure:

[0051] 1. The alloy bushing 200 and the copper-silver-zinc alloy ring 100 are chemically cleaned with hydrochloric acid solution and 40% by volume nitric acid aqueous solution respectively, so as to remove the oxide film and oil stain on the surface of the parts.

[0052] 2. Electroplate a layer of copper on the copper-silver-zinc alloy ring 100 .

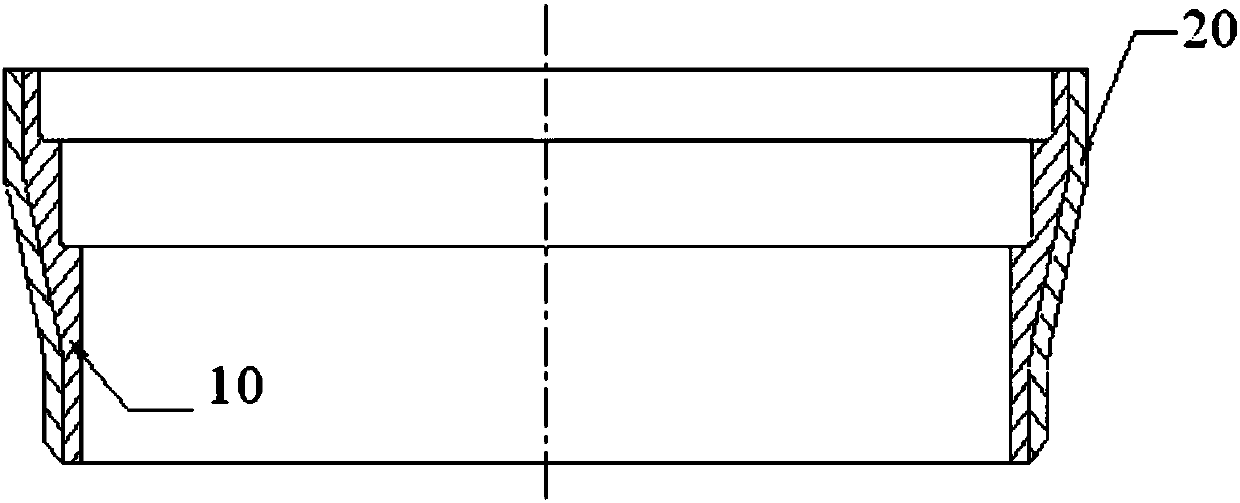

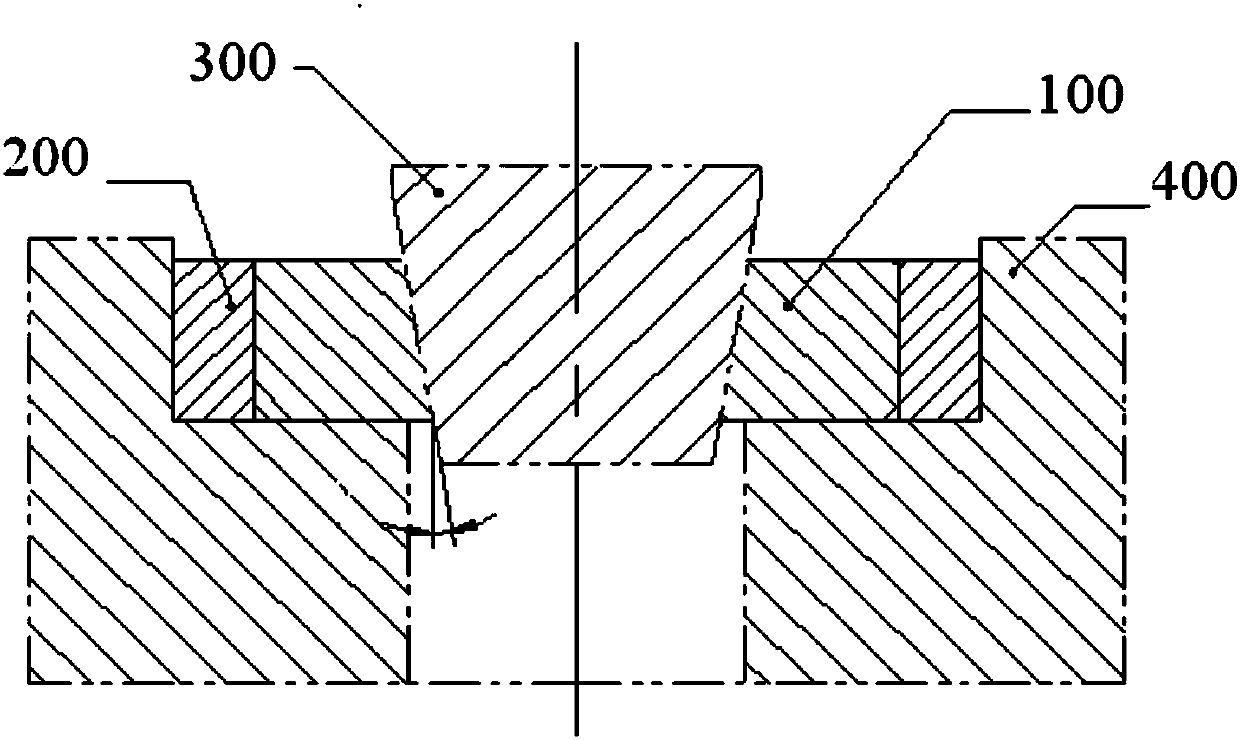

[0053] 3. Brush the flow blocking agent on the contact surface between the mandrel 300 and the copper-silver-zinc alloy ring 100, the copper-silver-zinc alloy ring 100 and the block 400, and the contact surface between the alloy bush 200 and the block 400, and put the alloy bush 200 and copper-silver-zinc alloy ring 100 are assembled. The alloy bushing 200 and the copper-silver-zinc alloy ring 100 are interference fit, and the interference fit is 0.03 mm. Both the inner hole of the copper-silver-zinc alloy ring 100 and the taper of the mandrel 300 are 8°.

...

Embodiment 2

[0056] Follow the steps below to prepare the engine sealing structure:

[0057] 1. The alloy bushing 200 and the copper-silver-zinc alloy ring 100 are chemically cleaned with hydrochloric acid solution and 40% by volume nitric acid aqueous solution respectively, so as to remove the oxide film and oil stain on the surface of the parts.

[0058] 2. Electroplate a layer of copper on the alloy bushing 200 .

[0059] 3. Brush the flow blocking agent on the contact surface between the mandrel 300 and the copper-silver-zinc alloy ring 100, the copper-silver-zinc alloy ring 100 and the block 400, and the contact surface between the alloy bush 200 and the block 400, and put the alloy bush 200 and copper-silver-zinc alloy ring 100 are assembled. The alloy bushing 200 and the copper-silver-zinc alloy ring 100 are interference fit, and the interference fit is 0.04 mm. Both the inner hole of the copper-silver-zinc alloy ring 100 and the taper of the mandrel 300 are 10°.

[0060] 4. Inst...

Embodiment 3

[0062] Follow the steps below to prepare the engine sealing structure:

[0063] 1. The alloy bushing 200 and the copper-silver-zinc alloy ring 100 are chemically cleaned with hydrochloric acid solution and 40% by volume nitric acid aqueous solution respectively, so as to remove the oxide film and oil stain on the surface of the parts.

[0064] 2. Electroplate a layer of copper on the copper-silver-zinc alloy ring 100 .

[0065] 3. Brush the flow blocking agent on the contact surface between the mandrel 300 and the copper-silver-zinc alloy ring 100, the copper-silver-zinc alloy ring 100 and the block 400, and the contact surface between the alloy bush 200 and the block 400, and put the alloy bush 200 and copper-silver-zinc alloy ring 100 are assembled. The alloy bushing 200 and the copper-silver-zinc alloy ring 100 are an interference fit, and the interference fit is 0.05 mm. Both the inner hole of the copper-silver-zinc alloy ring 100 and the taper of the mandrel 300 are 12°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com