Containerless casting molding method of frozen sand mold

A technology of moldless casting and sand molding, which is applied in the direction of casting molding equipment, casting mold components, casting molds, etc., and can solve the problems of high cost, environmental pollution, and easy pollution of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

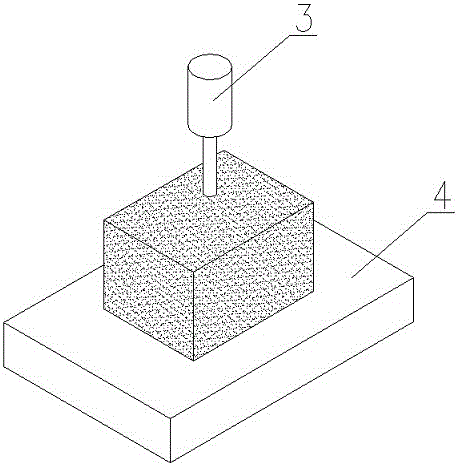

[0019] The implementation process of the present invention will be described in detail below in conjunction with the accompanying drawings.

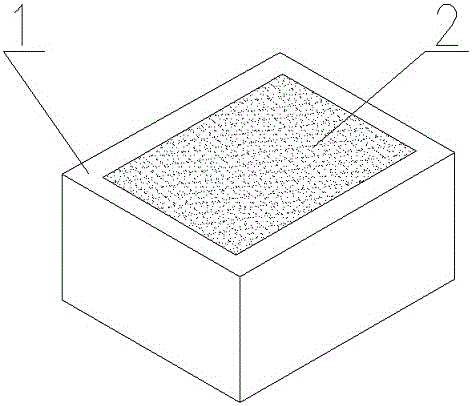

[0020] The present invention is a moldless casting forming method for frozen sand molds. The molding sand (1) can be quartz sand or non-quartz sand according to different requirements of castings, and the mesh number can be 40 / 70, 50 / 100, 70 / 140, 100 / 200, the binder can be water or solution, according to a certain mass fraction of 1%-10%, freeze and solidify at a certain temperature of 0°C-40°C to make a sand blank, and directly cut it into a mold on a forming machine. The specific implementation steps of the method of the present invention are as follows.

[0021] The present invention takes a certain sand mold lower box as an example, and the steps are as follows.

[0022] Step 1: According to the technical requirements of the present invention, select silica sand with a particle size of 70 / 140 mesh commonly used for casting, use wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com