Production process of a solid rod high-silicon cast iron anode

A high-silicon cast iron anode and production process technology, applied in the directions of casting molds, casting mold components, manufacturing tools, etc., can solve the problems of difficulty in guaranteeing the quality of castings, high silicon and chromium content, and poor impact resistance. Remove the effects of poor surface quality, good thermal insulation performance, and smooth outer surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

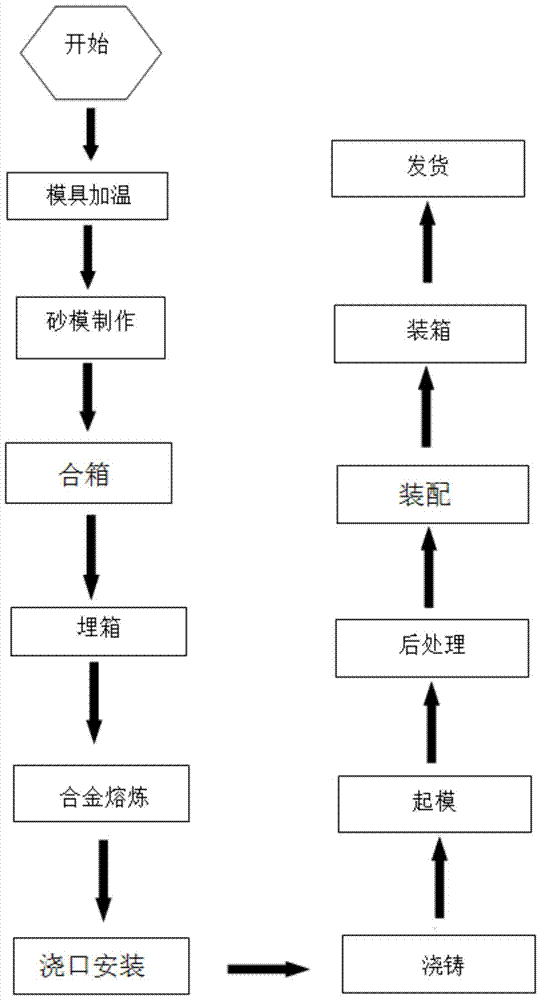

[0024] see figure 1 , in the embodiment of the present invention, a solid rod high-silicon cast iron anode production process, the specific steps are as follows:

[0025] (1) Mold heating: clean the surface of the rod model, and turn on the power to heat the rod model;

[0026] (2) Sand mold making: When the rod model is heated to 190°C, cover the special coated sand on the model according to a certain thickness to ensure uniform coverage, close the cover plate for heating, and the sand core at 200°C Heating for 10 minutes under the same conditions, after confirming that the sand core is sintered and formed, open the sand core for cooling;

[0027] (3) Closing box: install the formed sand mold on the inner sand core, and buckle the upper and lower sand molds together with fasteners;

[0028] (4) Buried box: Put the buckled sand box into the casting sand pile, bury it, press it tightly, and install the casting port;

[0029] (5) Alloy smelting: Put the alloy materials into t...

Embodiment 2

[0037] see figure 1 , a solid rod high-silicon cast iron anode production process, the specific steps are as follows:

[0038] (1) Mold heating: clean the surface of the rod model, and turn on the power to heat the rod model;

[0039] (2) Sand mold making: When the rod model is heated to 200°C, cover the special coated sand on the model according to a certain thickness to ensure uniform coverage, close the cover plate for heating, and the sand core at 200°C Heating for 12 minutes under the same conditions, after confirming that the sand core is sintered and formed, open the sand core for cooling;

[0040] (3) Closing box: install the formed sand mold on the inner sand core, and buckle the upper and lower sand molds together with fasteners;

[0041] (4) Buried box: Put the buckled sand box into the casting sand pile, bury it, press it tightly, and install the casting port;

[0042] (5) Alloy smelting: Put the alloy materials into the melting furnace in proportion and in orde...

Embodiment 3

[0050] see figure 1 , in the embodiment of the present invention, a solid rod high-silicon cast iron anode production process, the specific steps are as follows:

[0051] (1) Mold heating: clean the surface of the rod model, and turn on the power to heat the rod model;

[0052] (2) Sand mold making: When the rod model is heated to 210°C, cover the special coated sand on the model according to a certain thickness to ensure uniform coverage, close the cover plate for heating, and the sand core at 200°C Heating for 15 minutes under the same conditions, after confirming that the sand core is sintered and shaped, open the sand core for cooling;

[0053] (3) Closing box: install the formed sand mold on the inner sand core, and buckle the upper and lower sand molds together with fasteners;

[0054] (4) Buried box: Put the buckled sand box into the casting sand pile, bury it, press it tightly, and install the casting port;

[0055] (5) Alloy smelting: Put the alloy materials into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com