A glue coating device and glue coating method for damping sheet isolation paper

A technology of gluing device and release paper, which is applied to devices and coatings for coating liquid on the surface, can solve problems such as adhesion of damping sheets, and achieve the effects of facilitating fixing and installation, maintaining tightness and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

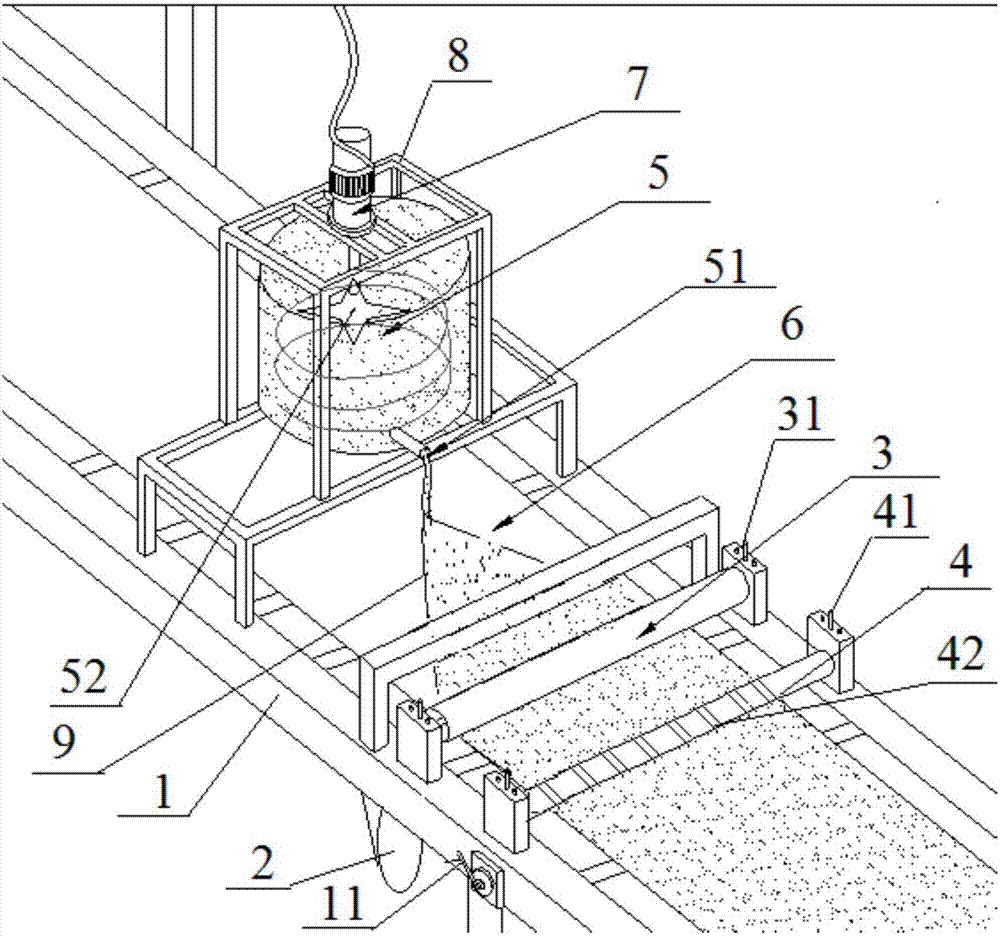

[0040] A kind of damping sheet release paper gluing device of the present embodiment, such as figure 1 As shown, it includes an operation table 1, a release paper roll holder 2 and a water-based glue barrel 5, and also includes a thinning roller 3 and a water-based glue thinning belt 6, wherein: the operation table 1 has a slightly downward-sloping structure, and the release paper roll holder 2 is fixed on The bottom of the console 1; the water-based glue bucket 5 and thinning roller 3 are fixed on the upper surface of the console 1 according to the process sequence; one end of the water-based glue thinning belt 6 is fixed on the bottom of the water-based glue bucket 5, and the discharge port 51 is flushing the water-based glue thinning belt 6. The other end is fixed on the surface of the console 1 at the bottom of the thinning roller 3; after the release paper is unfolded by the release paper roll holder 2, the end passes through the bottom of the thinning roller 3, and the en...

Embodiment 2

[0043] A damping sheet release paper gluing device of this embodiment has the same basic structure as that of Embodiment 1, and the improvement is that it also includes a pressure roller 4 that is parallel to the thinning roller 3 and arranged along the process direction. Distributed with 8 grooves 42, the length of the pressing roller 4 is 330mm, the groove spacing is 30mm, the width is 10mm, and the depth is 2.5mm. Squeeze adjustment mechanisms 41 are arranged at both ends to adjust the gap between the pressing roller 4 and the release paper. between gaps. Pressure-sensitive adhesive viscosity ≤ 15g / min, fluidity 2.0.

[0044] A method for applying glue to the release paper by the damping sheet release paper gluing device of this embodiment, the steps are:

[0045] A. Pull out the end of the silicon-coated release paper on the release paper roll stand 2, pass it through the bottom of the thinning roller 3, and then pass through the bottom of the pressure roller 4, and the s...

Embodiment 3

[0053] The basic structure of the damping sheet release paper gluing device of this embodiment is the same as that of Embodiment 2, and the improvement is that: an agitator 7 is installed in the water-based glue bucket 5; the bottom end of the agitator 7 is fixedly connected with a star-shaped stirring blade 52; the spacing of the grooves 42 is 4cm;

[0054] When the damping sheet release paper gluing device of this embodiment is used specifically, in step B, the agitator 7 is turned on at the same time, the star-shaped agitating blade 52 forms a vortex for the agitation of the rubber material, and a stable flow rate is formed for the discharge port 51. Discharging; in step D, the amount of glue flow can be controlled by reducing the stirring speed of the agitator 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com