Efficient pulping device

A kind of refining and high-efficiency technology, applied in the direction of grain processing, etc., can solve the problems of waste, soymilk yield reduction, etc., and achieve the effect of low cost, compact structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

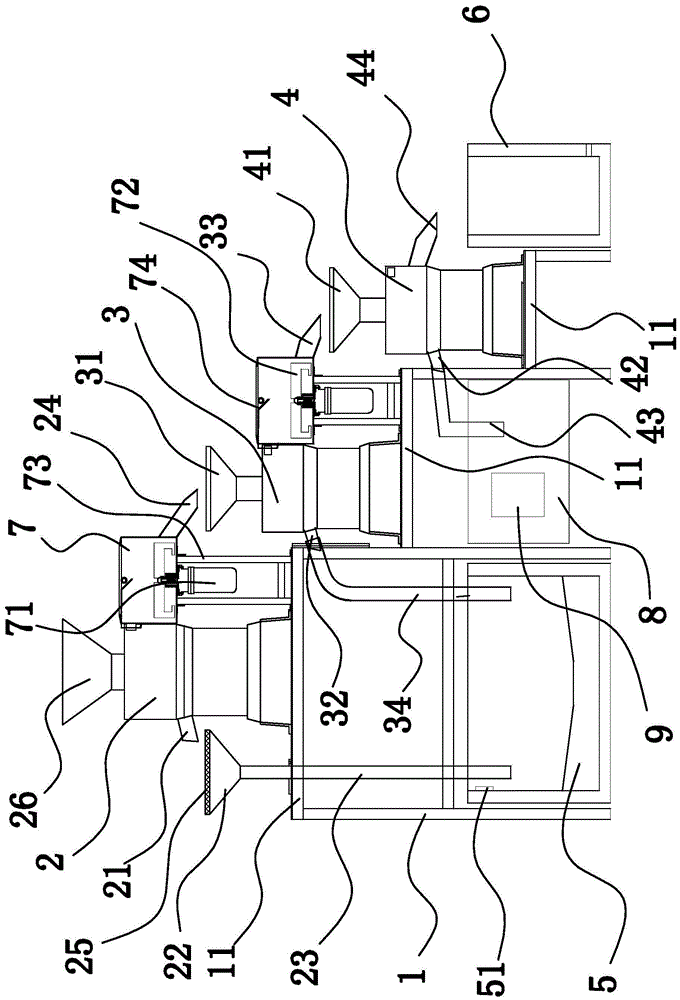

[0020] Such as figure 1 The high-efficiency refining device includes a base 1, a refiner, a slurry collecting tank 5, and a slag collecting tank 6. The slurry collecting tank 5 is located inside the base 1, and the base 1 has three steps 11 with gradually decreasing height. The three refiners are respectively fixed on the three steps 11, and the slurry collecting hopper 22 is provided under the slurry outlet 21 of the No. 1 refiner 2, and the slurry collecting hopper 22 is connected to the slurry tank 5 through the slurry pipe 23. In the middle, the bottom of the slag discharge pipe port 24 of the No. 1 refiner 2 is directly opposite to the feed port 2 31 of the No. 2 refiner 3, and the discharge port 2 32 of the No. 2 refiner 3 extends through the slurry collection pipe 2 34 Into the slurry tank 5, the bottom of the slag discharge pipe port 33 of the second refiner 3 is directly opposite to the feed port 341 of the third refiner 4, and the liquid collection tank is set directl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com